Method for using submarine propeller thruster capable of deeply diving over kilometers at tail end of submarine main body of seat cabin

A technology of propeller propellers and submarines, which is applied in the direction of underwater ships, warships, special-purpose ships, etc., and can solve problems such as short cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

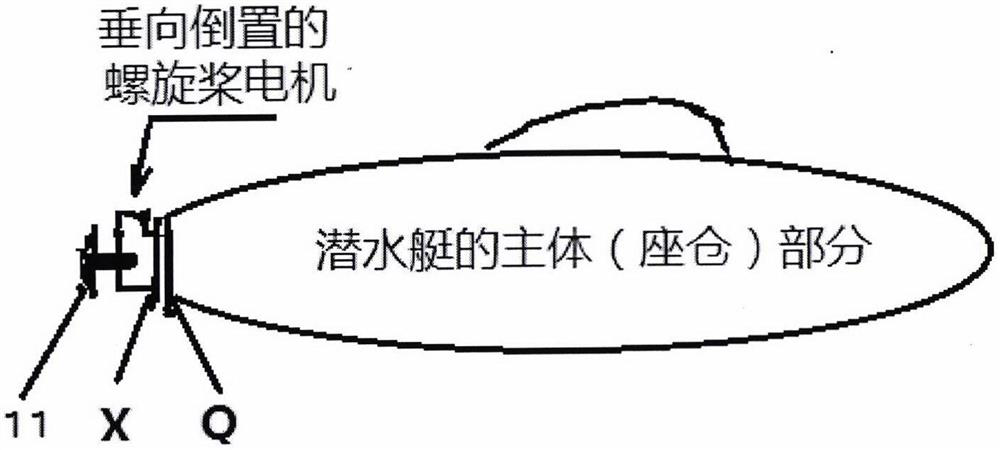

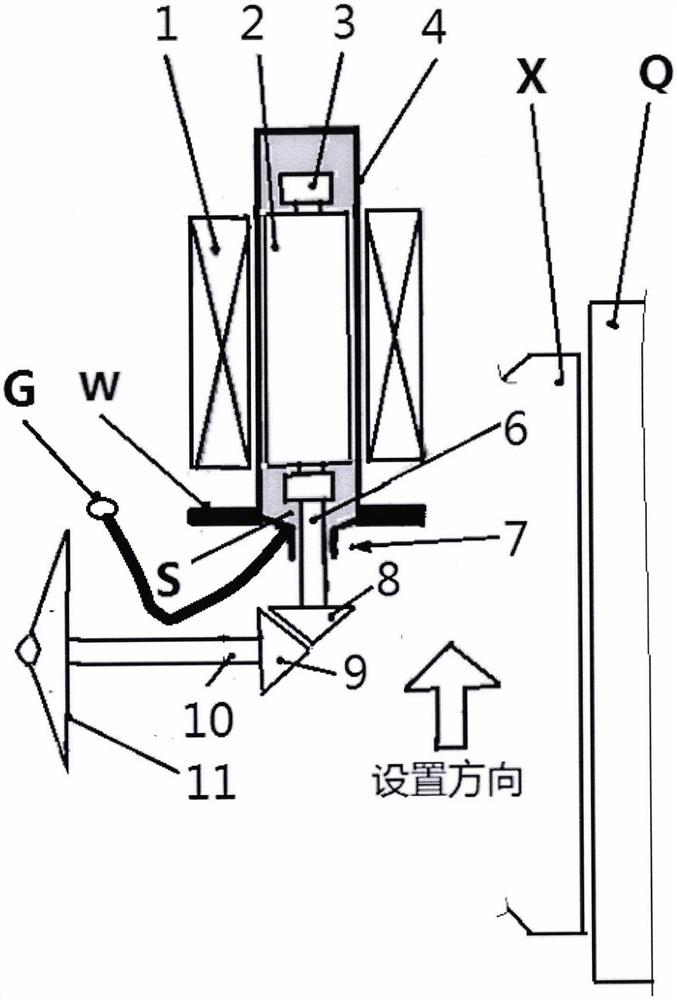

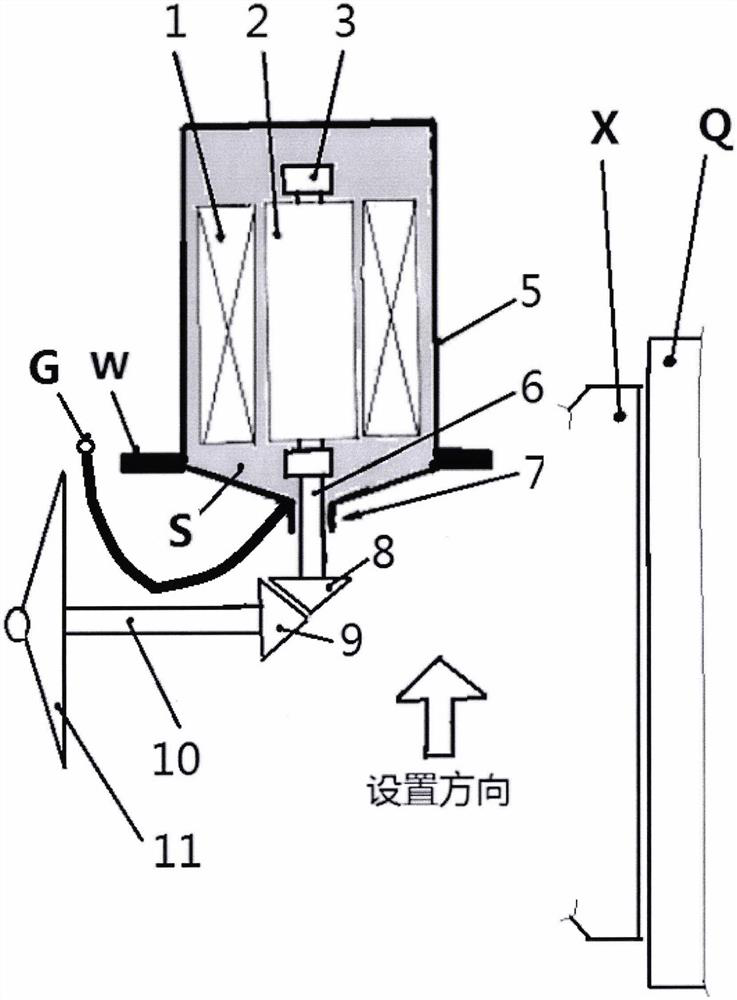

[0020] according to figure 1 Schematic representation: the electric propeller propeller of the submarine as an independent part of the present invention is equipped with the tail of another submarine main body (cockpit) part as an independent part, and belongs to the detachable connecting plate between the two independent entities Mechanism "X-Q" is removable. - This is advantageous for the waterproof sealing effect under the condition of extremely high pressure difference. Below, combine figure 2 A more detailed analysis can be made.

[0021] In order to realize the above-mentioned purpose of the present invention, intend to adopt following technical scheme:

[0022] The present invention includes:

[0023] (1) A motor made of both the rotor 2 and the stator 1 embedded in the winding, and the vertical gear 8 of the vertical shaft 6 in the motor is coupled with the horizontal gear 9 of the screw rod 10 and the motor torque is output to the screw rod 10 propeller 11;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com