Primary epitaxial growth dual-wavelength semiconductor laser device

An epitaxial growth, dual-wavelength technology, used in semiconductor lasers, semiconductor laser excitation devices, lasers, etc., can solve the problems of low yield of semiconductor bonding processes, many influencing factors, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

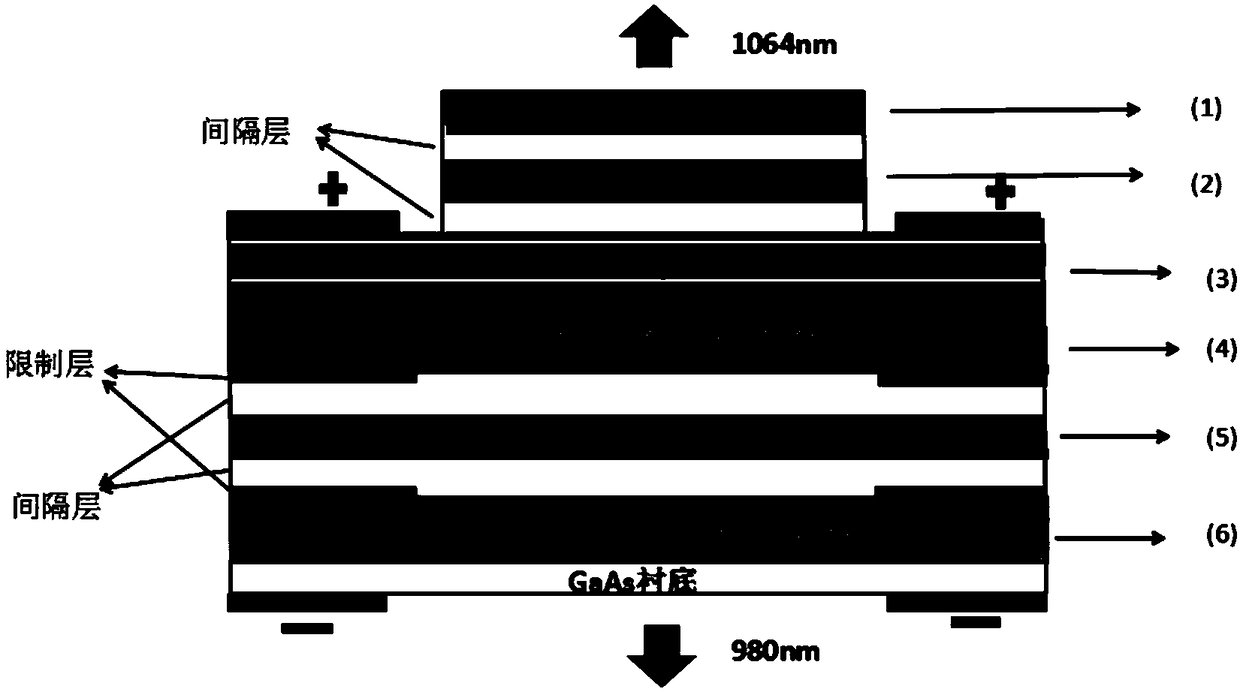

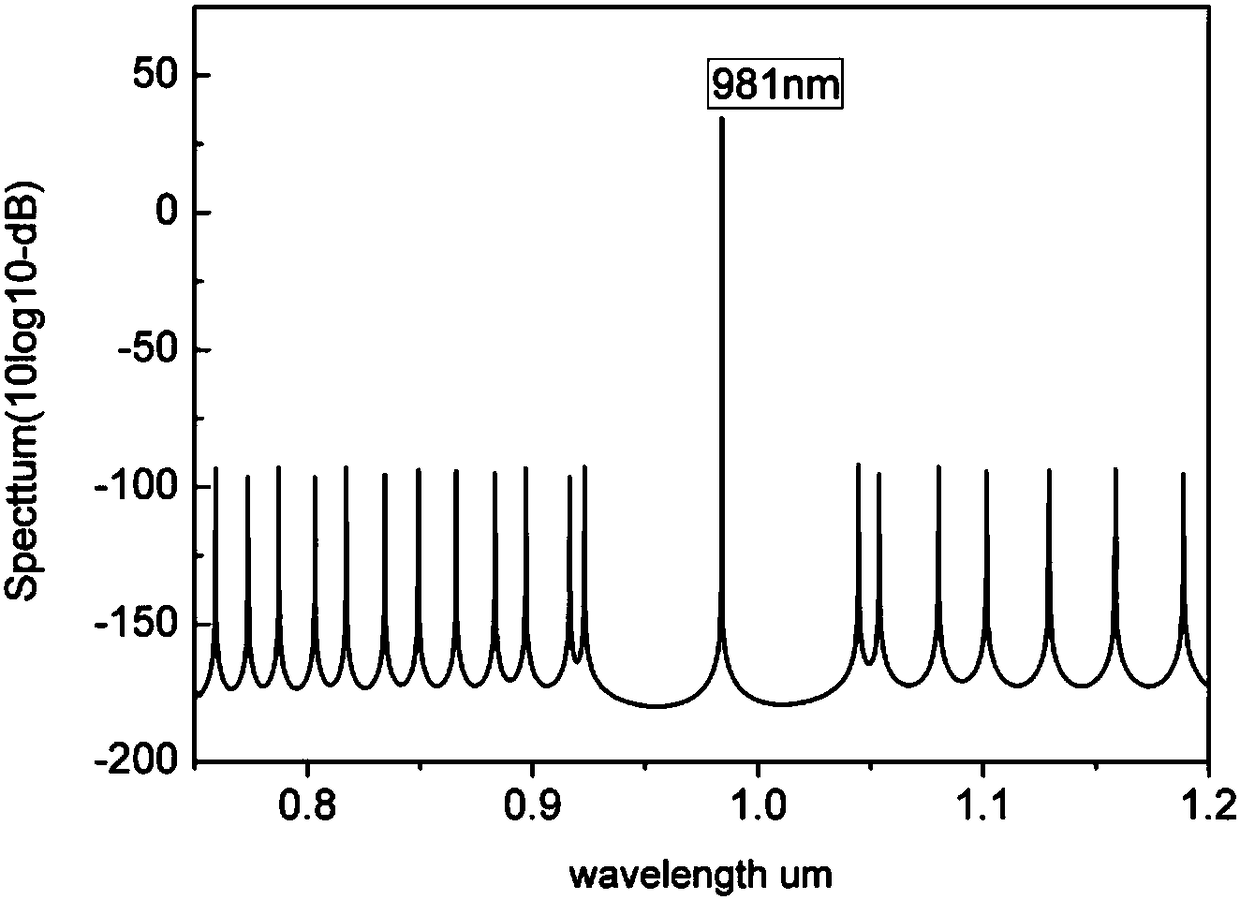

[0046] In this embodiment, the pump light vertical cavity and the excited vertical cavity respectively adopt an integrated vertical cavity structure combining a 980nm vertical cavity and a 1064nm vertical cavity, and the 980nm vertical cavity includes two parts of GaAs / Al 0.9 GaAs DBR, AlGaAs spacer layer, InGaAs / GaAs multi-quantum active region, oxidation confinement layer. 1064nm vertical cavity includes upper and lower parts GaAs / Al 0.9 GaAs DBR, AlGaAs spacer layer, InGaAs / GaAs multi-quantum active region, in order to make the 980nm vertical cavity emit light simultaneously, so the design of the lower DBR is 22 pairs, and the reflectivity is 99.86%. Considering the lower DBR of the 1064nm vertical cavity The reflection of 980nm light is affected, so when using Crosslight software to simulate, the lower DBR of the 1064nm vertical cavity is added to the simulated structure, such as Figure 11 As shown, optimize the number of DBRs on the 980nm vertical cavity, and determine ...

Embodiment 2

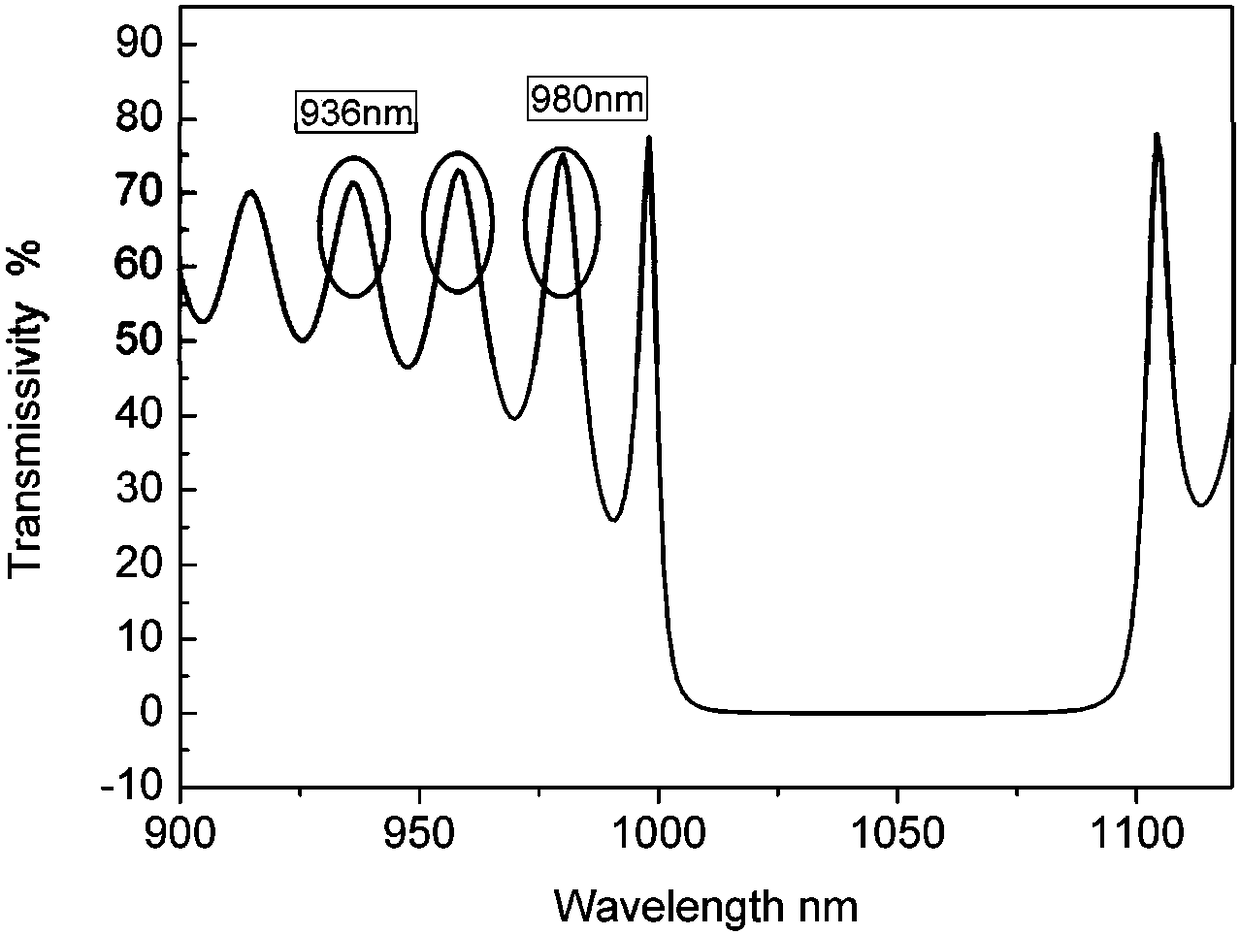

[0048] In this embodiment, the pump light vertical cavity and the excited vertical cavity respectively adopt an integrated vertical cavity structure combining a 936nm vertical cavity and a 1064nm vertical cavity, and the 936nm vertical cavity includes two parts of GaAs / Al 0.9 GaAs DBR, AlGaAs spacer layer, InGaAs / GaAs multi-quantum active region, oxidation confinement layer. 1064nm vertical cavity includes upper and lower parts GaAs / Al 0.9 GaAs DBR, spacer layer, InGaAs / GaAs multi-quantum active region, DBR logarithms designed for pump light sources of different wavelengths are different. In order to make the 936nm vertical cavity emit light simultaneously in the upper and lower directions, the number of lower DBRs is designed to be 21 pairs. The ratio is 99.835%, and considering the influence of the lower DBR of the 1064nm vertical cavity on the reflection of 936nm light, the lower DBR of the 1064nm vertical cavity is also added to the simulated structure during the simulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com