Non-standard part purchasing decision-making system based on manufacturing capability and relation chain

A technology of manufacturing capability and decision-making system, applied in marketing, equipment, business, etc., can solve the problems of supplier evaluation methods, human intervention, lack of scientific basis, etc., and achieve the effect of reliable decision-making support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

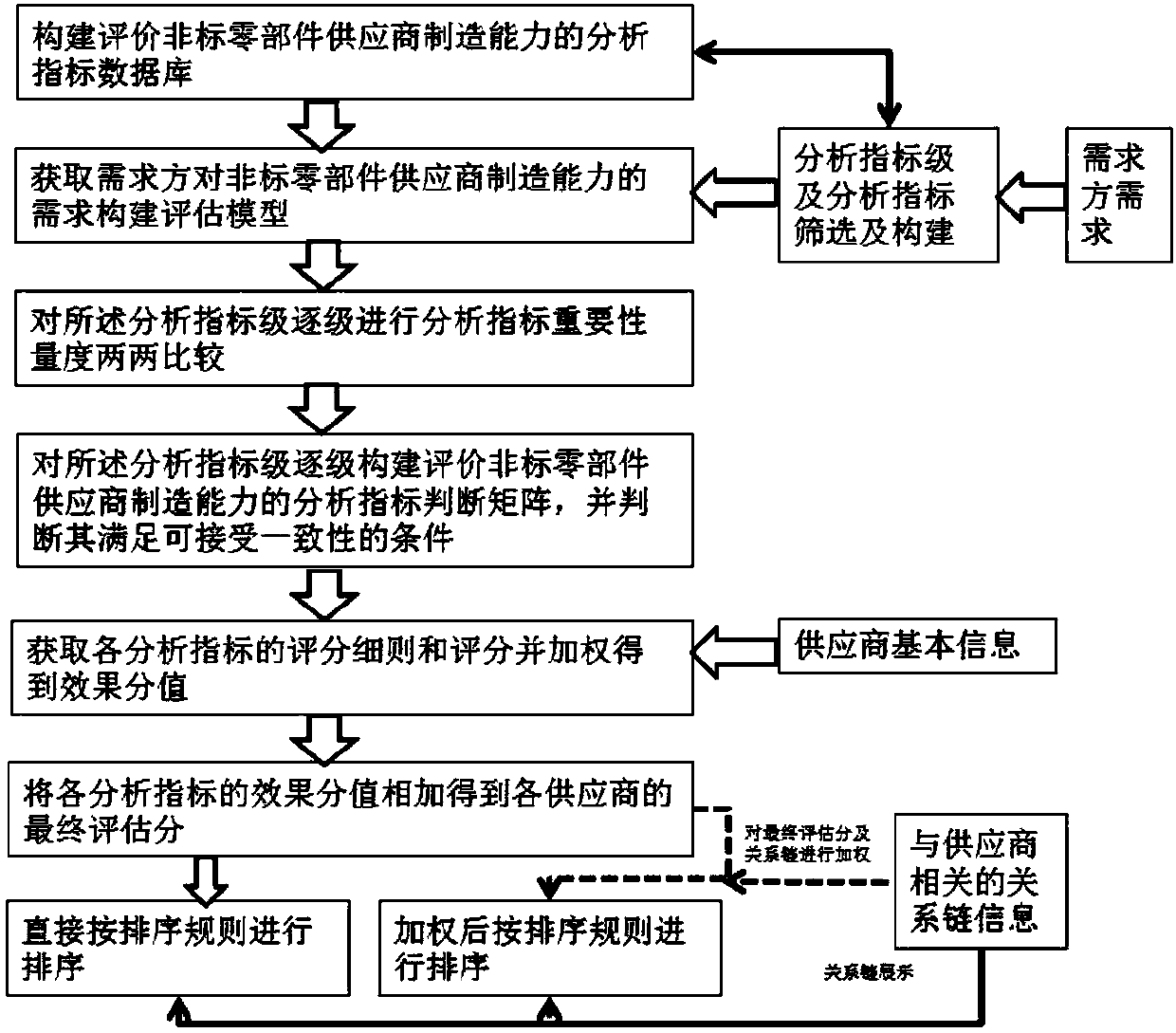

[0020] Below in conjunction with embodiment and with reference to accompanying drawing Figure 1-4 The present invention is described in further detail.

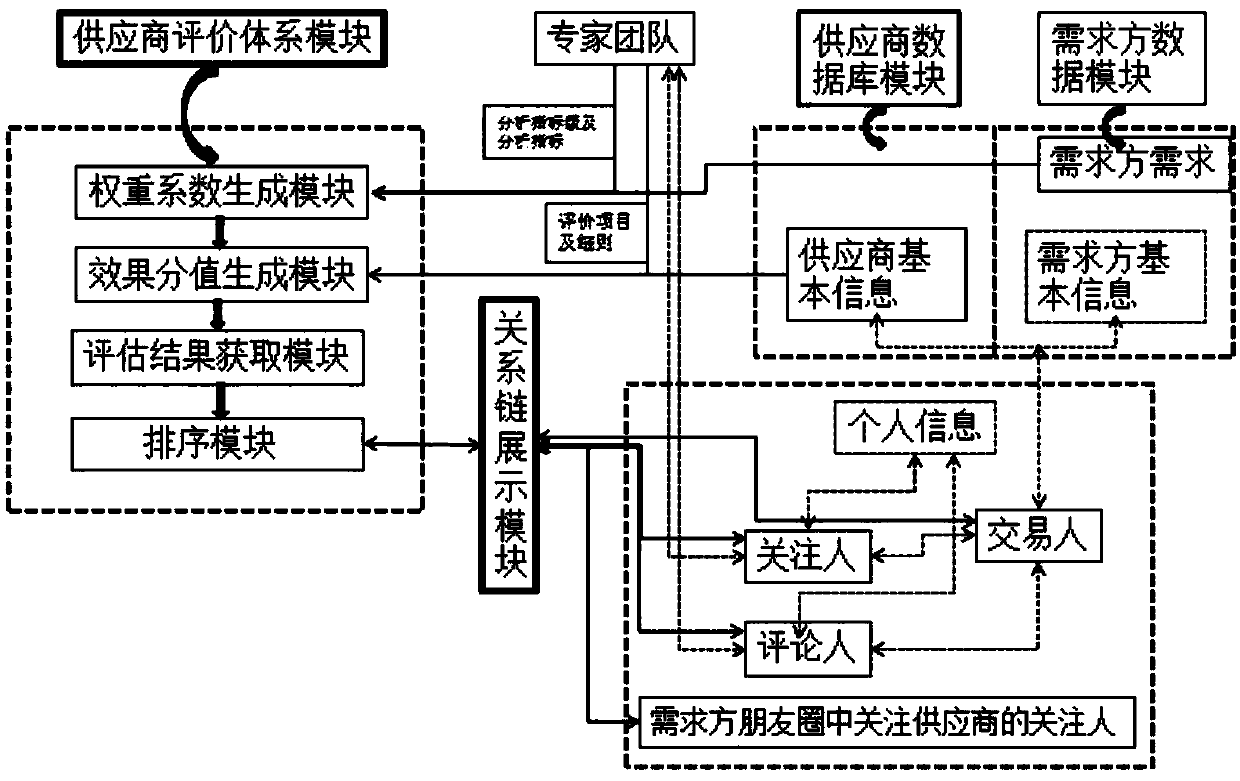

[0021] A non-standard component procurement decision-making system based on manufacturing capabilities and relationship chains invented, characterized in that the system includes a supplier database module, a supplier evaluation system module, and a relationship chain display module, and the supplier database module includes Various data of all suppliers, the supplier evaluation system module is based on the supplier database module and converts various data of suppliers into evaluation scores of 0-10, calculates the total score of each supplier according to the evaluation scores, and finally evaluates The suppliers are sorted, and the relationship chain display module displays the relationship chain information associated with each supplier.

[0022] Further, in the non-standard spare parts procurement system based on manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com