Intermediate cache device control system

A device control and caching technology, applied in general control systems, control/adjustment systems, program control, etc., can solve non-automation problems, avoid abnormal conditions, reduce personnel operating frequency, and avoid disconnection and no-load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

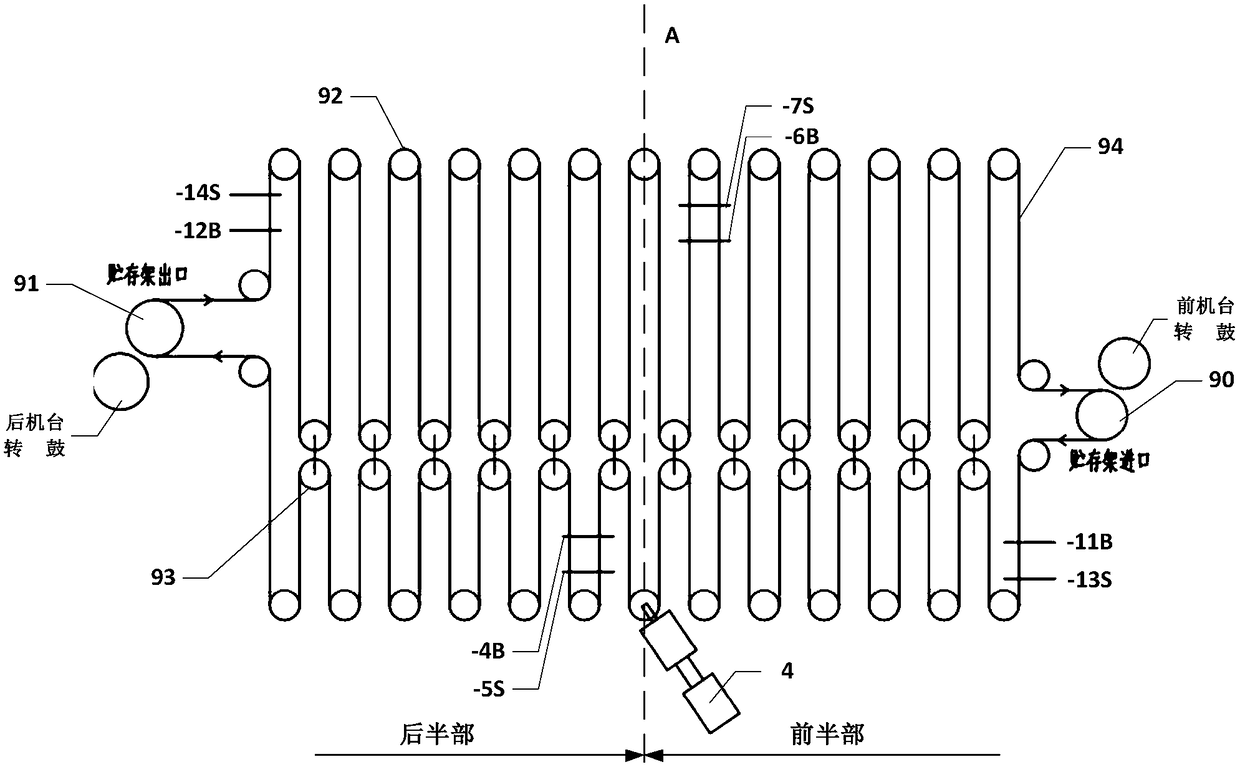

[0028] The embodiment of the present invention provides an intermediate buffer device control system, which is installed on the storage rack 9 on the aluminum can production line, and is used to control the storage tank of the storage rack 9 and automatically enter and exit the tank. Its main structure may include:

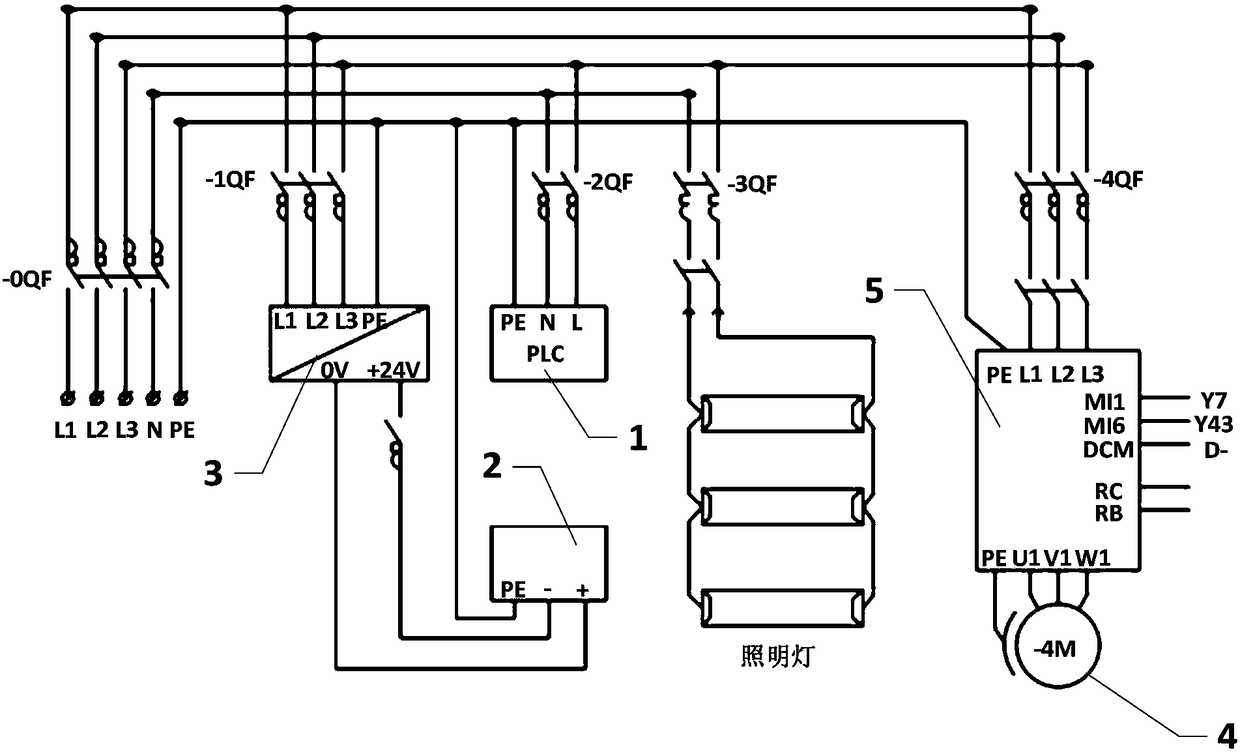

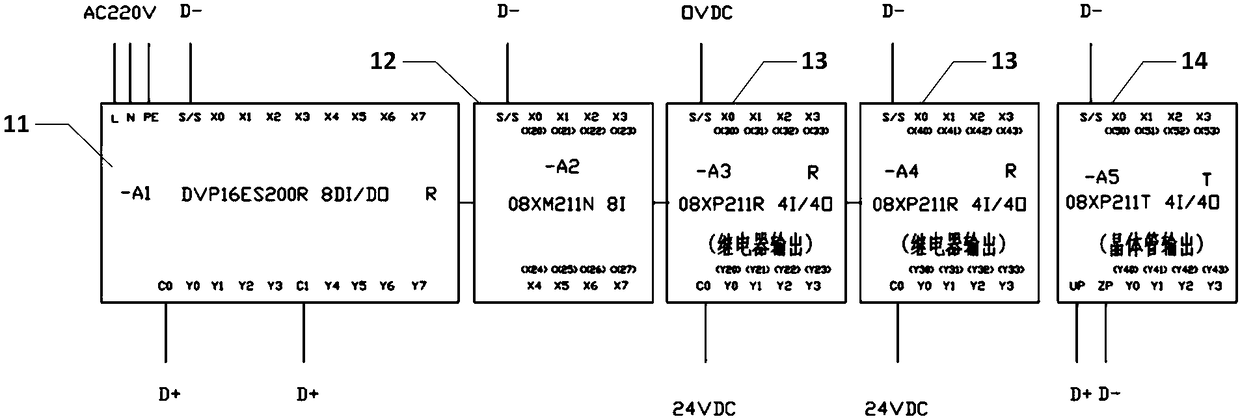

[0029] PLC control module 1, touch screen 2, switching power supply 3, motor with gear box 4, frequency converter 5, multiple proximity switches and multiple travel switches;

[0030] Such as figure 1 As shown in the main circuit diagram of , the switching power supply 3 is connected to the main line of the control system of the intermediate buffer device to provide working power for the control system of the intermediate buffer device; the PLC control module 1, the touch screen 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com