An environmental protection smoke exhaust device applied to a molding machine

A technology of smoke exhaust device and molding machine, which is applied in the direction of exhaust gas exhaust device, smoke and dust removal, cleaning method and utensils, etc., which can solve the problems affecting the quality of film production, and achieve the effect of avoiding pollution of the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

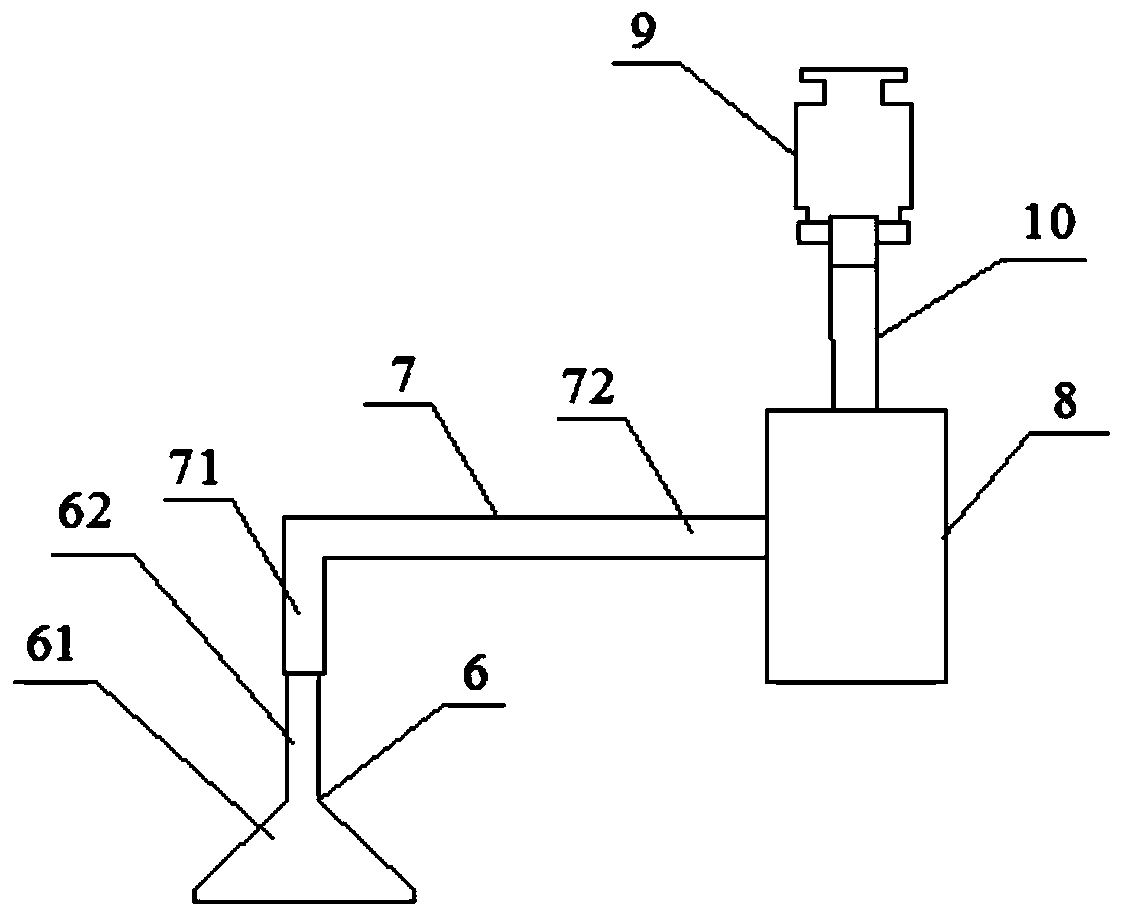

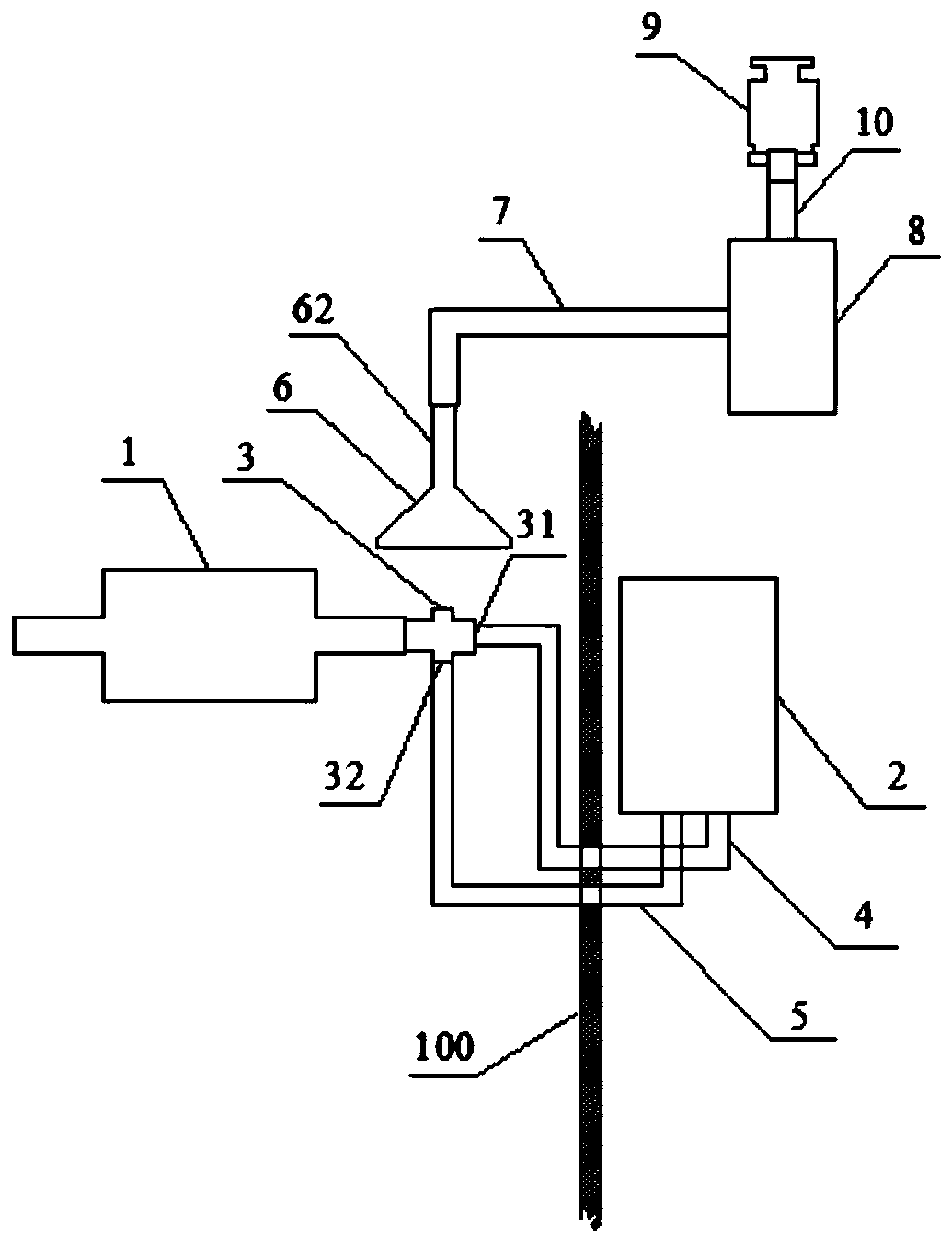

[0038] figure 2 Schematic diagram of the structure of the environmental protection smoke exhaust device applied to the molding machine provided by the embodiment of the present invention; image 3 The implementation scene diagram of the environmental protection smoke exhaust device applied to the molding machine provided by the embodiment of the present invention; Figure 4 Schematic diagram of the structure of the fume exhaust hood provided by the embodiment of the present invention.

[0039] see figure 2 and image 3 The environmental protection smoke exhaust device applied to the molding machine provided by the embodiment of the present invention includes: a smoke exhaust hood 6 , a first smoke exhaust pipeline 7 , a smoke exhaust fan 8 , a fume filter 9 and a second smoke exhaust pipeline 10 . After the environment-friendly smoke exhaust device provided in this embodiment is applied to the molding machine, it is used for real-time adsorption of oil fume generated at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com