Two-stage screw compressor and compression method

A screw compressor, screw technology, applied in the field of compressors, to achieve the effect of easy disassembly, reduce the risk of gas and water leakage, and avoid mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0019] Examples.

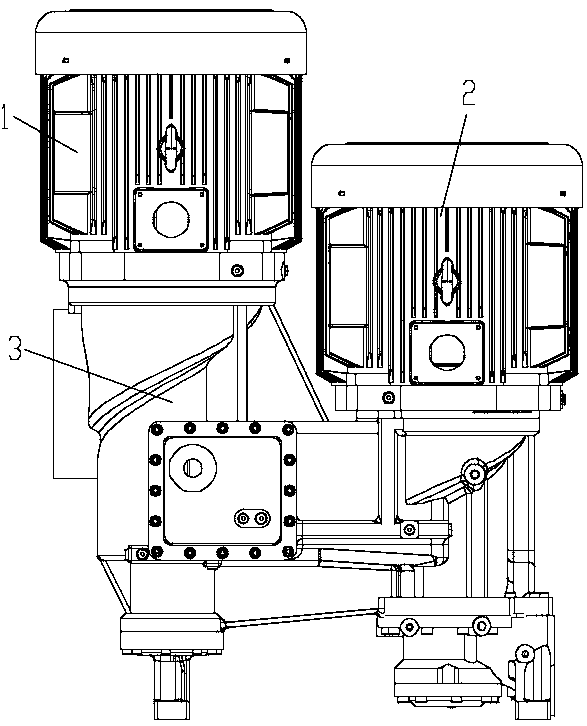

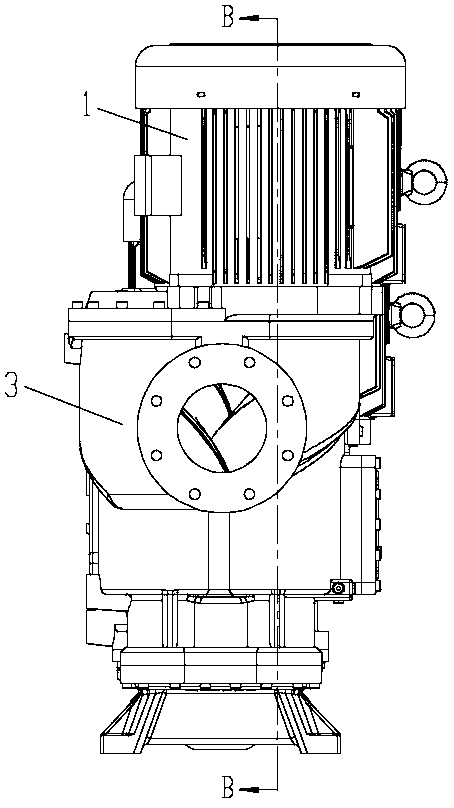

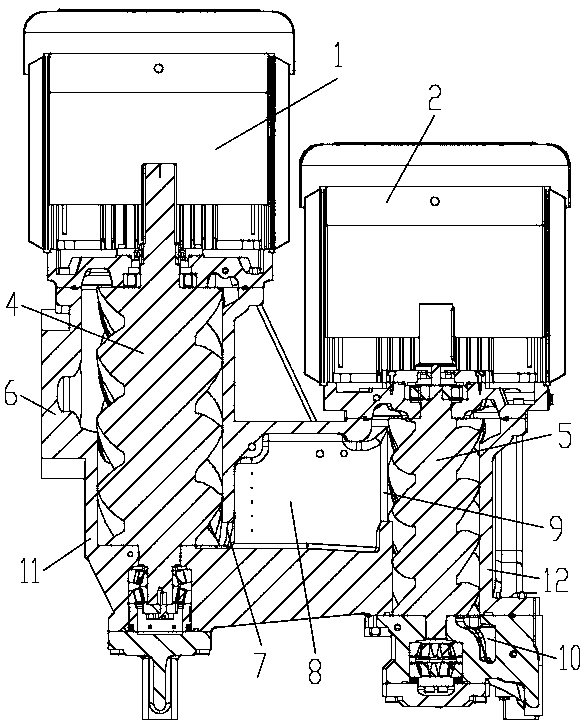

[0020] See Figure 1 to Figure 3 The two-stage screw compressor in this embodiment includes a main engine 3, a low-pressure stage drive 1 and a high-pressure stage drive 2. The two-stage screw compressor adopts a vertical structure, and the low-pressure stage drive 1 and the high-pressure stage drive 2 are both located above the main engine 3. , That is, the driver is on the top and the host 3 is on the bottom.

[0021] The host 3 in this embodiment includes a low-pressure stage housing 11, a high-pressure stage housing 12, a low-pressure stage screw 4 for first-stage compression of gas, and a stage for cooling the gas after the first-stage compression. The intermediate passage 8 and the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com