Method and system capable of utilizing methyl alcohol as additional energy to realize regeneration of particle catcher

A technology of particle trap and methanol, which is applied in the direction of machine/engine, electric control of exhaust treatment device, exhaust treatment, etc., can solve the problem that the collection efficiency of particle oxidation catalyst cannot meet the requirements of use, and improve the utilization efficiency, reduce frequency, and reduce vehicle and fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

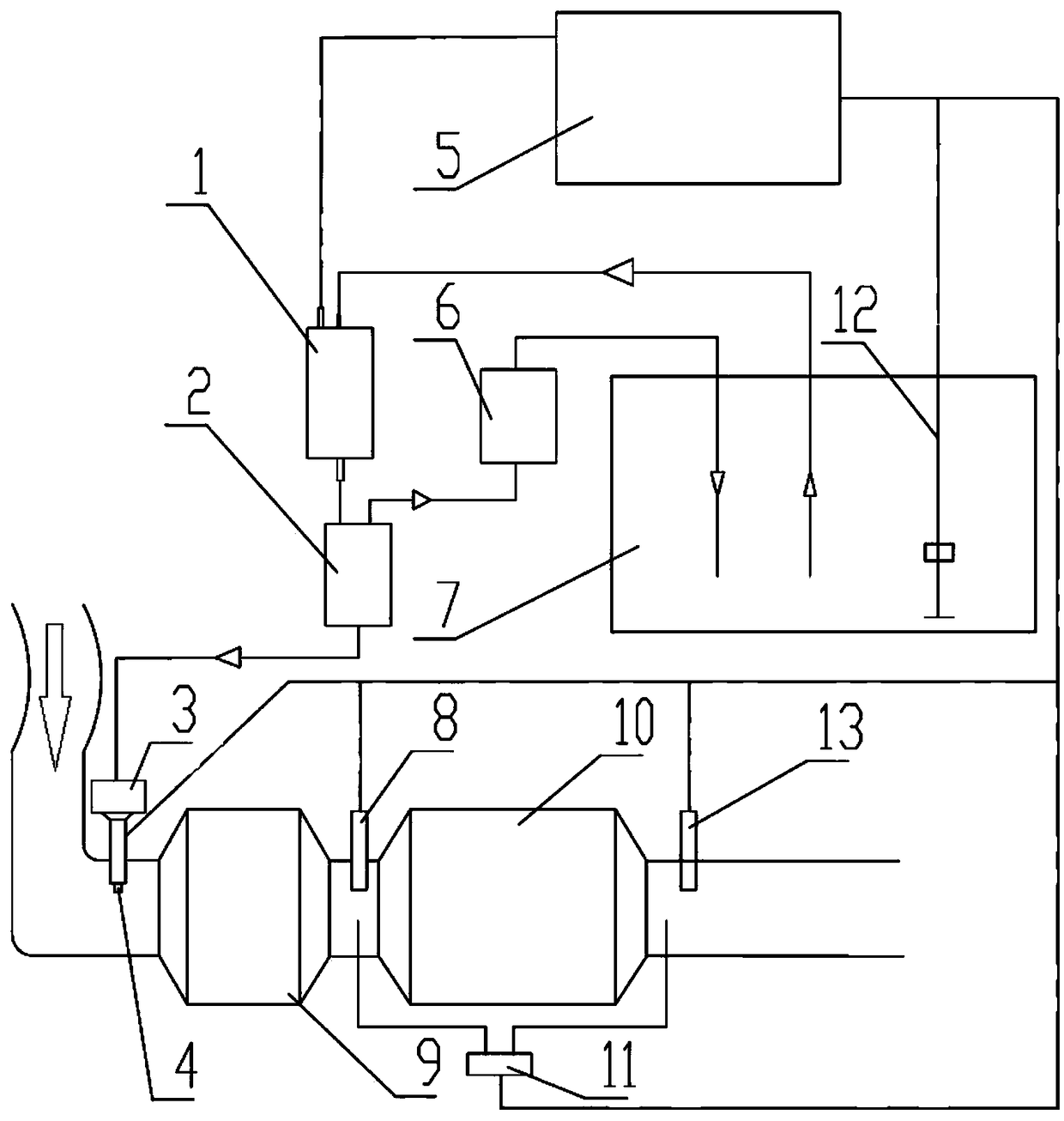

[0030] combine Figure 1-2 , to specifically describe the embodiments of the present invention.

[0031] A control system for realizing the regeneration of the diesel particulate filter, which includes: integrating a DOC post-processor 9 and a DPF post-processor 10 on the engine exhaust pipe, and installing an alcohol storage rail 3 and a methanol nozzle 4 upstream of the DOC post-processor; Methanol is sucked out of the methanol tank 7 by the methanol pump 1. After passing through the methanol filter 2, tiny impurities can be filtered out, and one path flows to the alcohol storage rail 3 and the methanol nozzle 4, and the other path flows to the pressure limiting valve 6. Methanol with a pressure exceeding 5 bar is returned to the methanol Box 7, the supply system can ensure that there is a stable and sufficient methanol with a pressure of 5 bar in the pipeline; the DOC post-processor 9 is installed downstream of the engine exhaust, with cordierite as the carrier, and the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com