Reciprocating type vibratory forced ramming hammer

A reciprocating, rammer technology, applied in the field of soft foundation treatment in the civil engineering industry, can solve the problems of foundation soil structure damage, no multi-level vibration effect, unfavorable pore water removal, etc., to reduce the number of times of ramming, increase the unit Sub-strong compaction, anti-damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

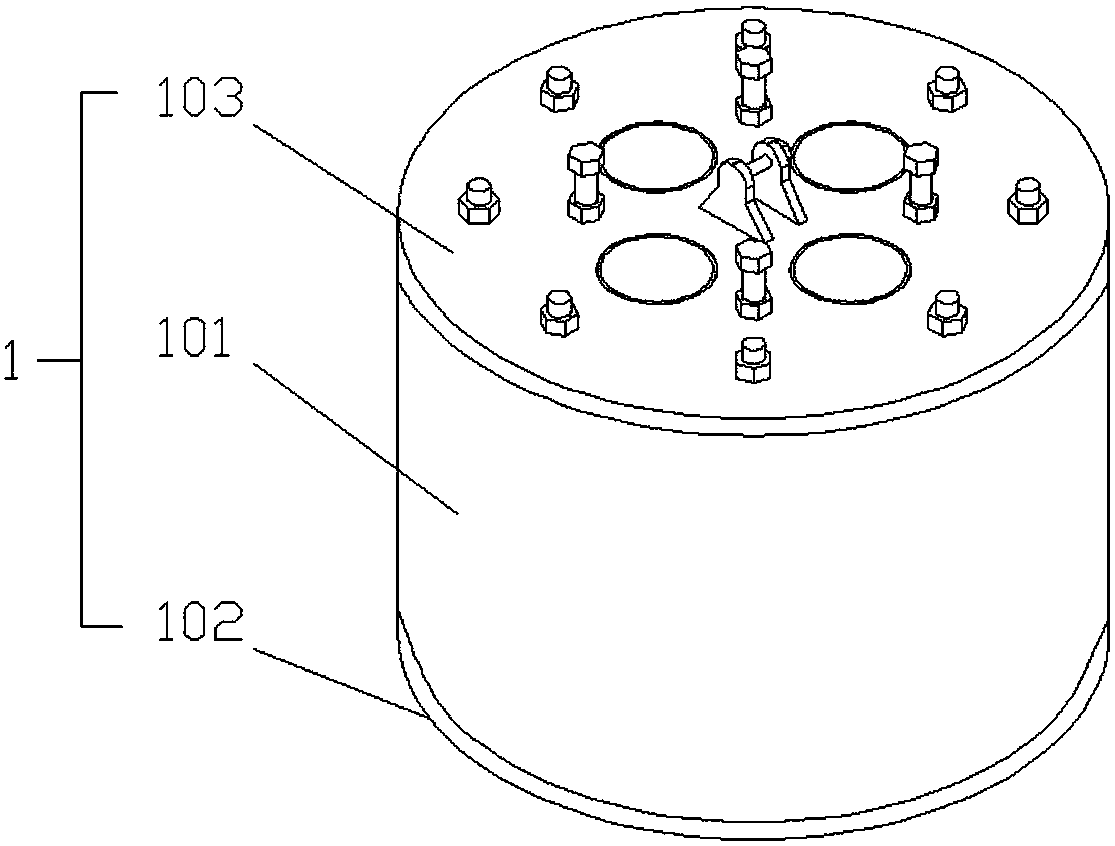

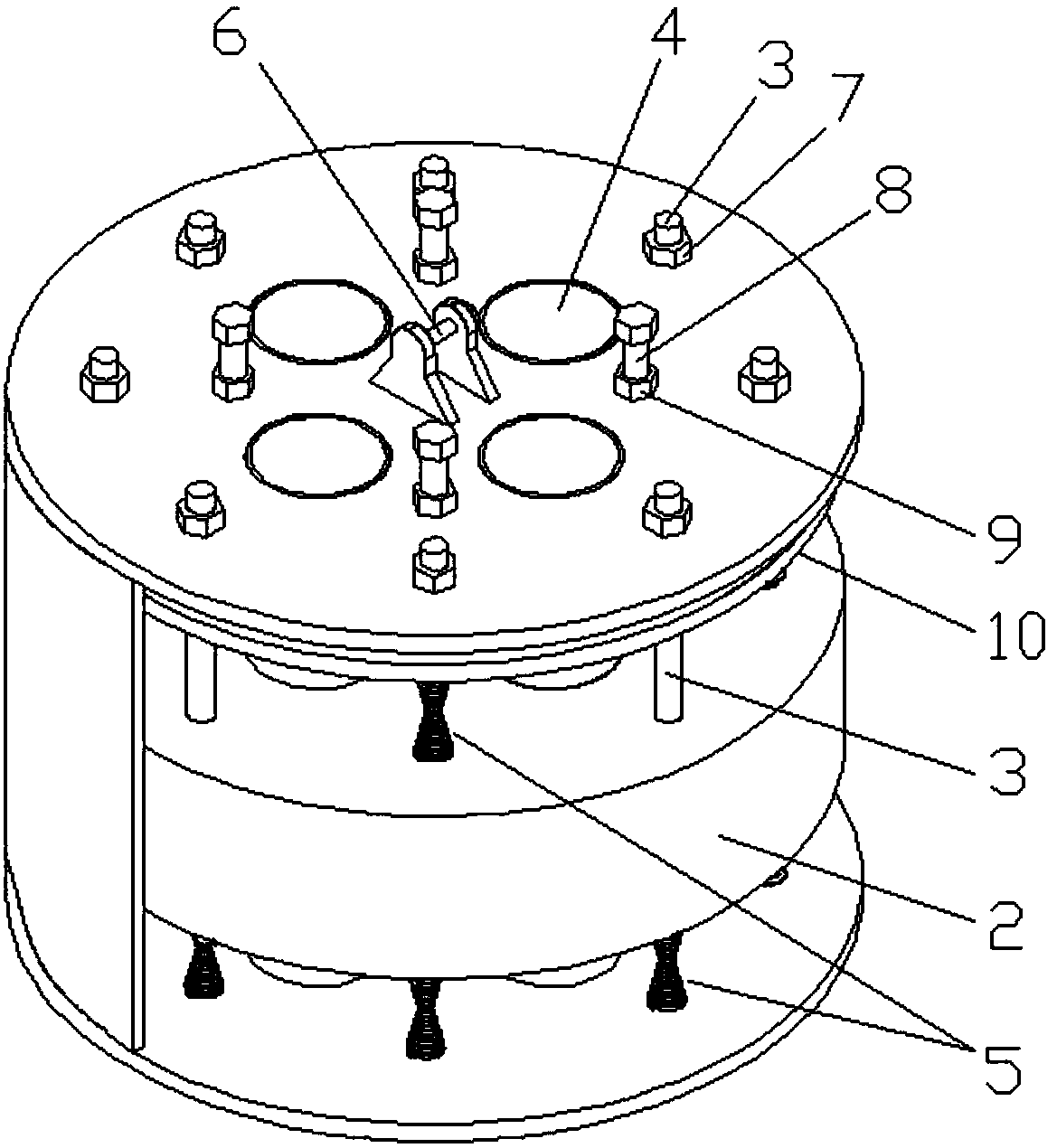

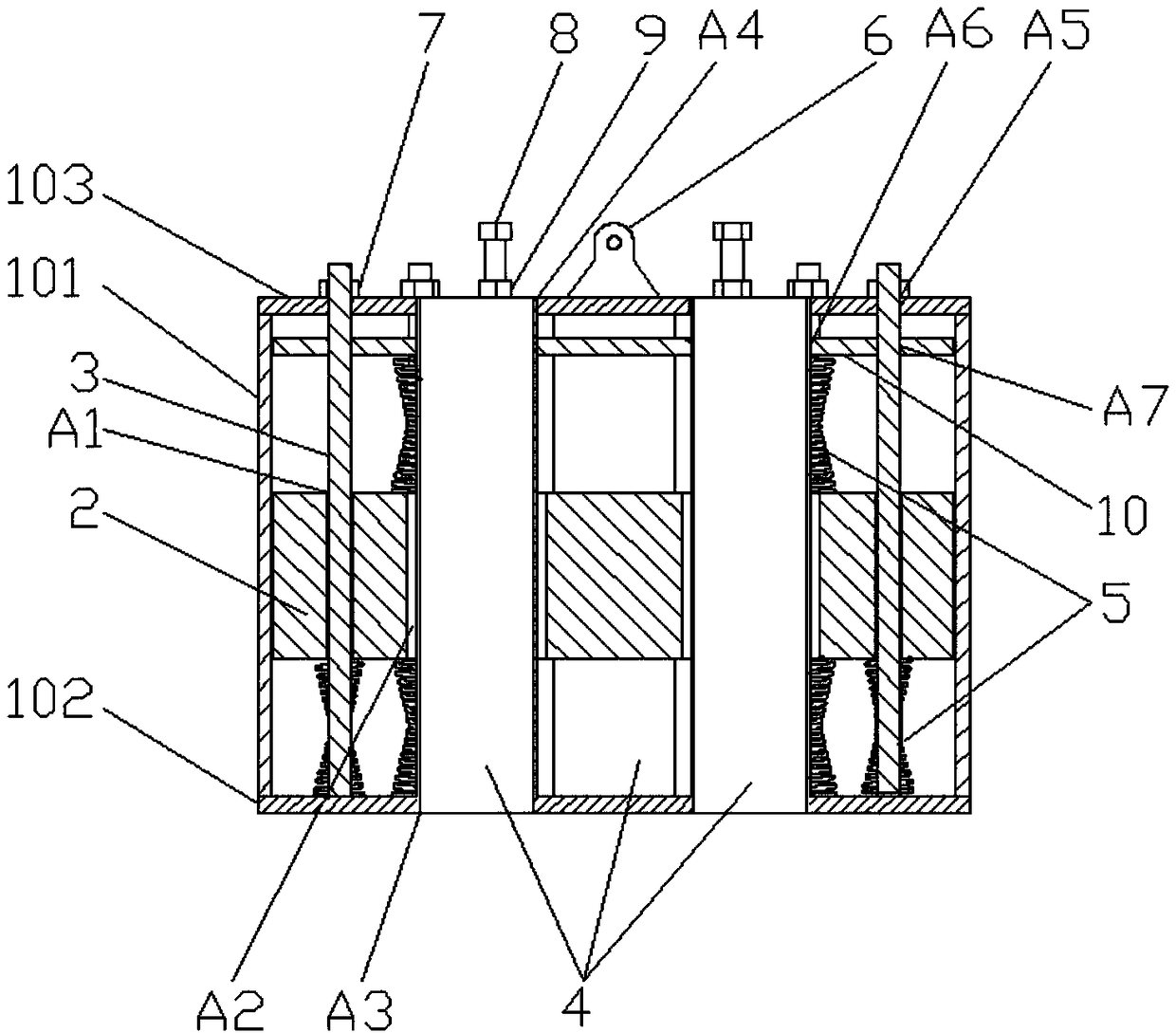

[0016] The structure of this embodiment includes a housing 1, a central vibrator 2, a guide rod 3, an exhaust cylinder 4, and a spring 5. The inside of the housing 1 is a cylindrical cavity, and the central vibrator 2 is arranged in the housing 1. The central vibrator 2 is provided with a plurality of first through holes A1, and a plurality of guide rods 3 respectively pass through the first through holes A1, and the upper and lower ends are respectively connected to the top and bottom of the housing 1, and the guide rods below the central vibrator 2 Section 3 is covered with a spring 5, the central vibrator 2 is also provided with a plurality of second through holes A2, the bottom of the housing 1 is provided with a third through hole corresponding to the second through hole A2, and the top of the housing 1 There is a fourth through hole corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com