The preparation method of zinc dibutyl dithiocarbamate

A technology of zinc dibutyldithiocarbamate and xylene, which is applied in the direction of organic chemistry, can solve the problems of low solvent and product recovery, waste liquid pollution of the environment, and cumbersome steps, and achieve manpower saving, high-efficiency production, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for preparing zinc dibutyl dithiocarbamate, wherein carbon disulfide is added dropwise to a reaction solution containing zinc oxide, dibutylamine, a dispersant and a first organic solvent for reaction, and dibutyl is obtained after the reaction is completed. Zinc dithiocarbamate;

[0029] The first organic solvent is insoluble in water, and the obtained zinc dibutyldithiocarbamate is insoluble or slightly soluble in the first organic solvent.

[0030] It should be noted that when the zinc dibutyldithiocarbamate is slightly soluble in the first organic solvent, the solubility of the zinc dibutyldithiocarbamate in the first organic solvent is not more than 1g / 100g.

[0031] The reaction materials used in the preparation method of the present invention are as follows:

[0032] Carbon disulfide: colorless or light yellow transparent liquid, pure product has the taste of ether, volatile, insoluble in water, soluble in most organic solvents suc...

Embodiment 1

[0055] This embodiment is a method for preparing zinc dibutyl dithiocarbamate, which includes the following steps:

[0056] Step a): At 15℃, add 240mL xylene, 5.15g zinc oxide, 0.027g fatty alcohol polyoxyethylene ether AEO-7 and 27.2g into a 1000mL four-necked flask equipped with electric stirring and dropping funnel. Dibutylamine is stirred and mixed uniformly to obtain a reaction solution;

[0057] Step b): Dissolve 16.07g of carbon disulfide in 12ml of xylene, maintain the temperature at 15°C, add the mixed solution of carbon disulfide and xylene dropwise to the reaction solution obtained in step a) for 0.6h, after the addition is complete, Continue to stir and react for 15 minutes, then heat to 26°C and react for 0.4 hours to end the reaction; the product is filtered, the filter cake is dried and crushed to obtain zinc dibutyl dithiocarbamate;

[0058] Step c): The first organic solvent is separated to remove the generated water and reused again.

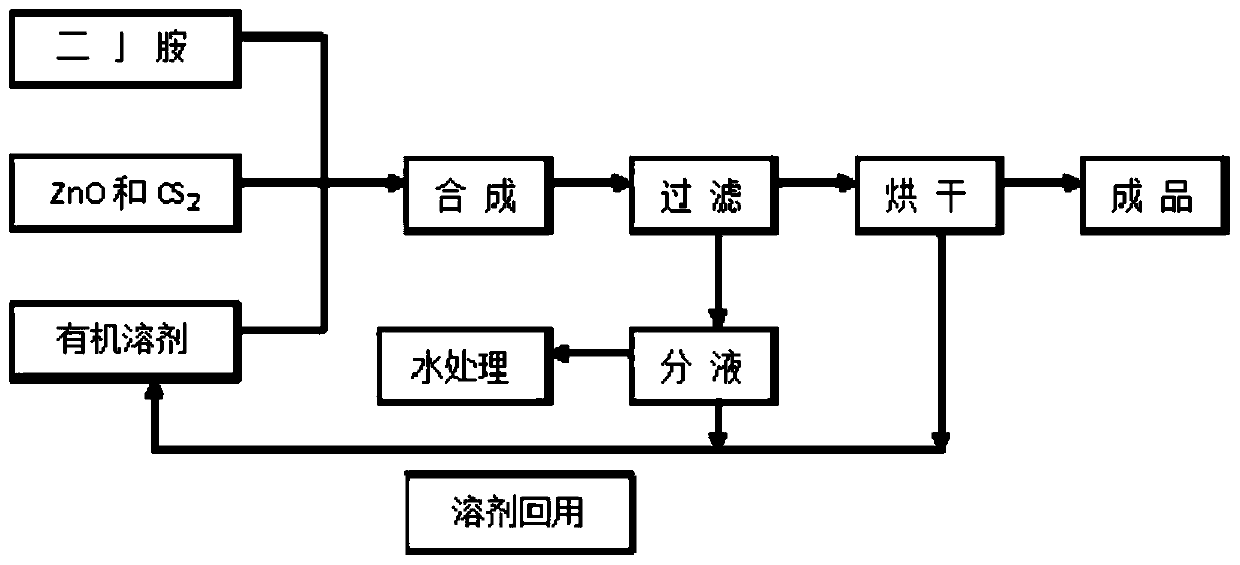

[0059] The process flow diagra...

Embodiment 2

[0061] This embodiment is a method for preparing zinc dibutyl dithiocarbamate, which includes the following steps:

[0062] Step a): Add 805 mL xylene, 12.02 g zinc oxide, 3.85 g fatty alcohol polyoxyethylene ether AEO-9 and 27.2 g in a 1000 mL four-neck flask equipped with electric stirring and dropping funnel at 13°C Dibutylamine is stirred and mixed uniformly to obtain a reaction solution;

[0063] Step b): Dissolve 20.89g of carbon disulfide in 112ml of xylene, maintain the temperature at 13°C, and add the mixed solution of carbon disulfide and xylene dropwise to the reaction solution obtained in step a) for 6.7 hours. After the addition is complete, Continue to stir and react for 50 minutes, then heat to 55°C and react for 2 hours to end the reaction; the product is filtered, the filter cake is dried and crushed to obtain zinc dibutyl dithiocarbamate;

[0064] Step c): The first organic solvent is separated to remove the generated water and reused again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com