Ultrafine powder full-automatic bag feeding and bag expanding packaging machine

A fully automatic, ultra-fine powder technology, applied in packaging, transportation and packaging, packaging types and other directions, can solve problems such as increased lung disease, powder diffusion, and impact on health, to prevent material leakage, ensure work safety, Control accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

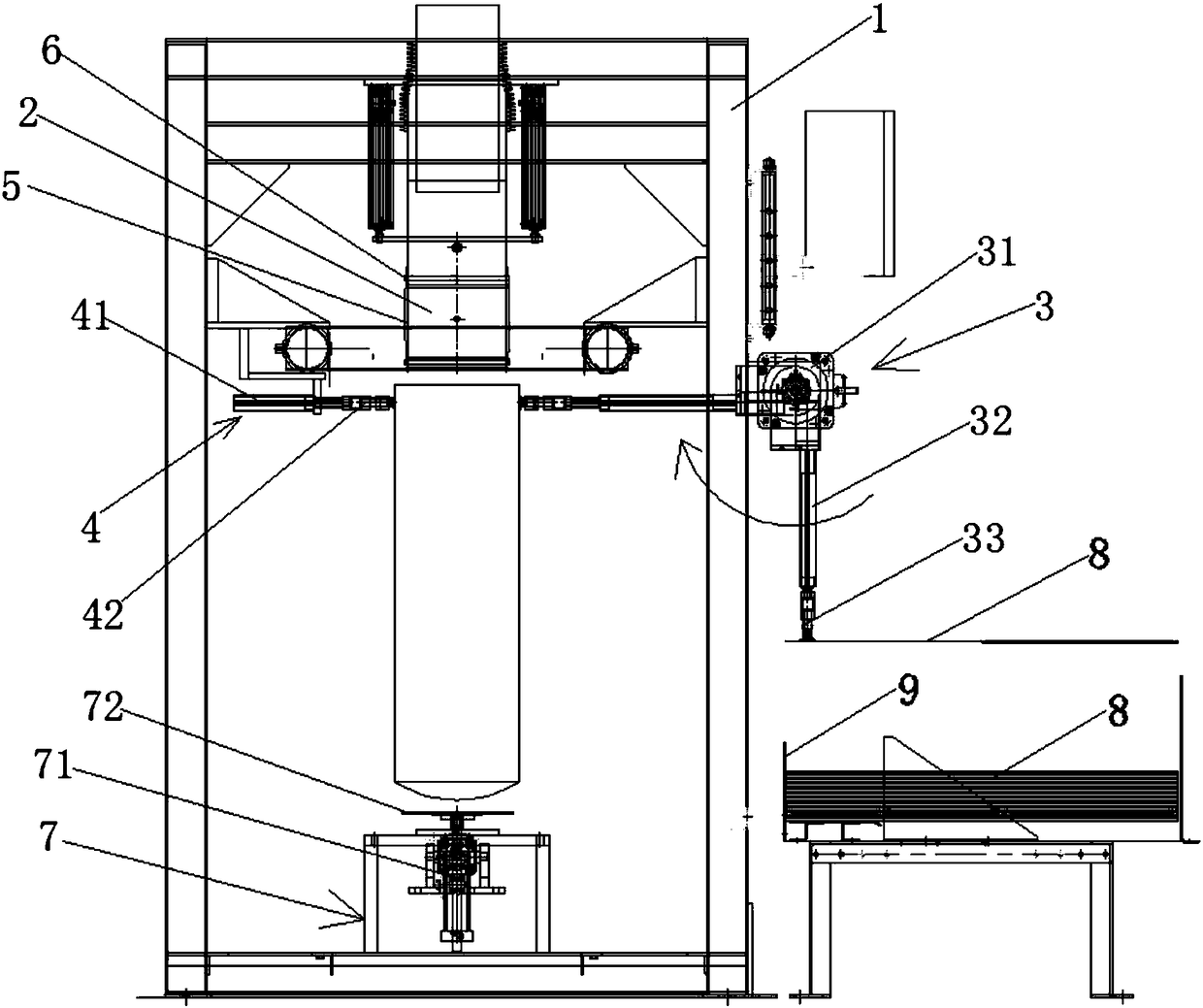

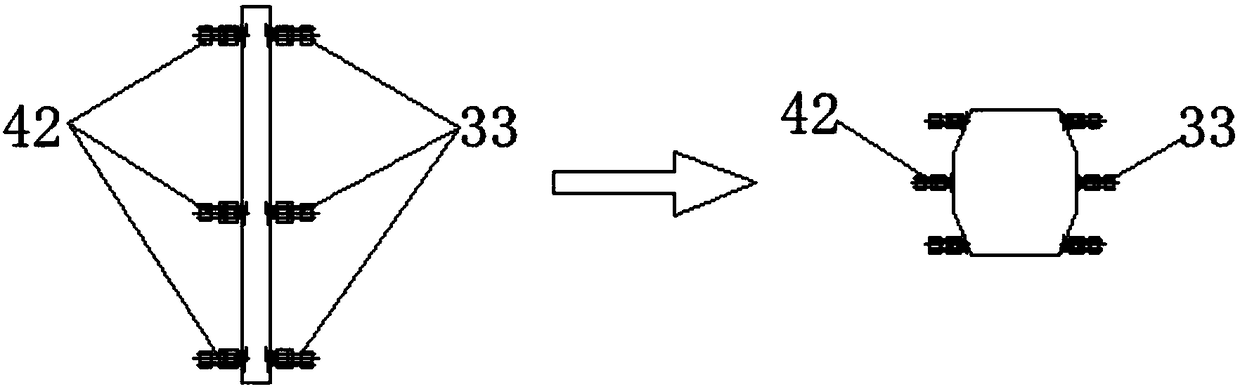

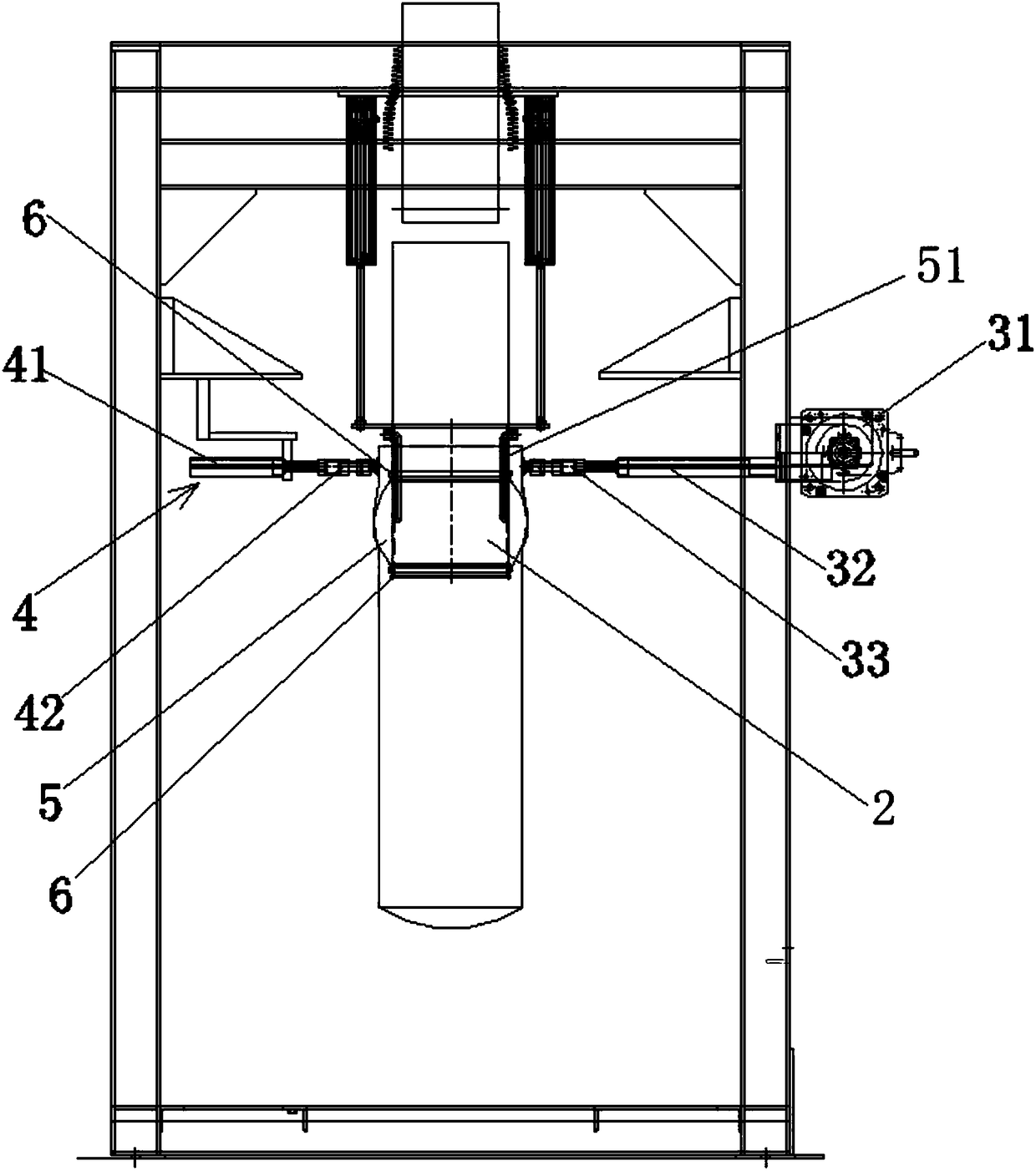

[0025] figure 1 It is a schematic diagram of the overall structure of the ultra-fine powder automatic bagging and bagging packaging machine according to an embodiment of the present invention, which shows the structural diagrams of the two states of bag taking and bag opening, focusing on the servo motor in the bag taking mechanism The state of the packaging bag in different positions; figure 2 yes figure 1 The schematic diagram of the transition of the bag opening state of the ultrafine powder automatic bagging and bagging packaging machine shown; image 3 yes figure 1 Shown is a schematic diagram of the structure of the ultrafine powder automatic bagging bagging packaging machine when the bagging bag is opened; the focus is on the structure of the bagging bag in the state of inflation.

[0026] This embodiment describes a kind of superfine powder automatic bag-up bag packing machine, such as figure 1 As shown, it can generally include a support frame 1, and a feeding tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com