Ecological blanket for fixing heavy metal and method of removing heavy metal in soil through combination of ecological blanket and phytoremediation

An ecological blanket and heavy metal technology, applied in the restoration of polluted soil, etc., can solve the problems of secondary pollution, long repair time, low biomass, etc., and achieve enhanced adsorption and treatment capacity, improved adsorption capacity, and high removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

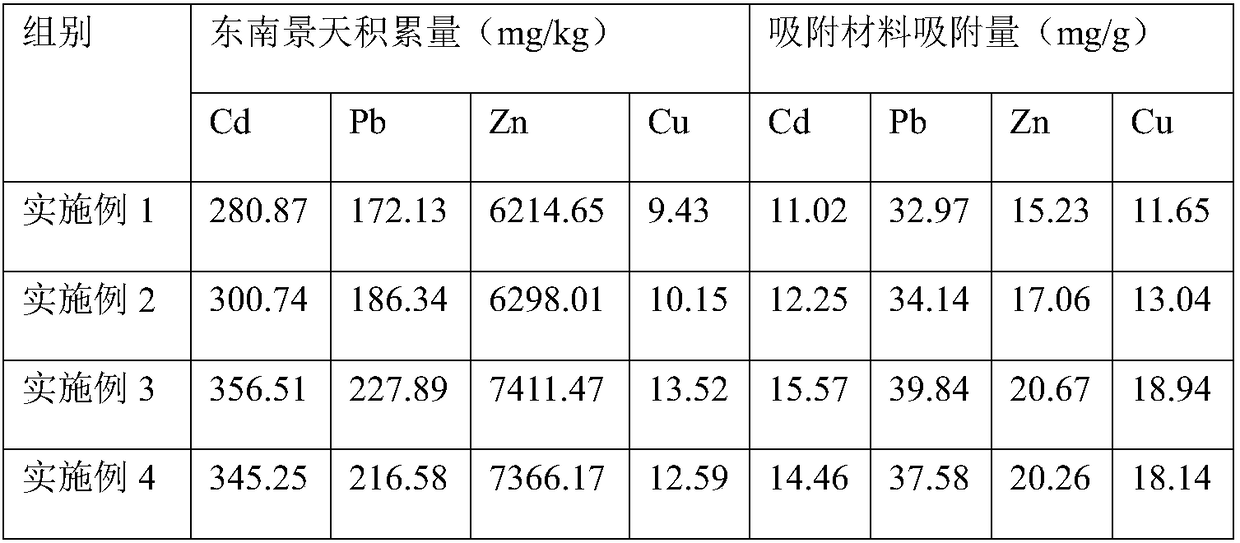

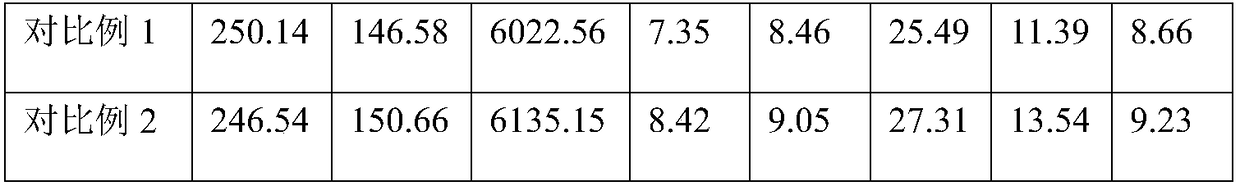

Examples

Embodiment 1

[0035](1) Preparation of interlayer zeolite: Add natural zeolite to 0.5mol / L NaCl solution, shake in a water bath at a constant temperature of 80°C for 5 hours, centrifuge and wash with deionized water; add the washed zeolite to 0.1 Treat in mol / L hydrochloric acid for 24 hours, wash with deionized water until neutral, shake at 160rpm at a constant temperature of 25°C for 30min, put the modified zeolite in an oven after cleaning, dry at 105°C for 2h; roast at 460°C for 3h, cool to room temperature, washed with deionized water, filtered, and dried at 105°C for 5 hours to obtain Na-type-acid-heat-treated modified zeolite with strong adsorption.

[0036] (2) Preparation of ecological blanket 1: two layers of polypropylene staple fiber needle-punched nonwoven geotextiles (purchased from Dezhou Xibei New Material Co., Ltd., product specification: SNGPP100) are laminated, and polyester filament spunbonded geotextiles are used on the upper and lower sides. Cloth (purchased from Dongg...

Embodiment 2

[0038] (1) Preparation of interlayer zeolite: Add natural zeolite to 1mol / L NaCl solution, shake in a water bath at a constant temperature of 80°C for 5 hours, centrifuge and wash with deionized water; add the washed zeolite to 0.3mol / L hydrochloric acid for 24 hours, washed with deionized water until neutral, oscillating at 160rpm at a constant temperature of 25°C for 30min, after cleaning, put the modified zeolite in an oven, dry at 105°C for 2h; roast at 450°C for 3h, and cool to At room temperature, wash with deionized water, filter, and dry at 105°C for 5 hours to obtain Na-type-acid-heat-treated modified zeolite with strong adsorption.

[0039] (2) Preparation of ecological blanket 2: Laminate two layers of polypropylene staple fiber needle-punched nonwoven geotextiles, cover the outer layer with polyester filament spunbonded geotextiles up and down, sew the edges of the four layers of geotextiles together, and the middle layer The modified zeolite prepared by filling s...

Embodiment 3

[0041] (1) Preparation of interlayer zeolite: Add natural zeolite to 1mol / L NaCl solution, shake in a water bath at a constant temperature of 80°C for 5 hours, centrifuge and wash with deionized water; add the washed zeolite to 0.3mol / L hydrochloric acid for 24 hours, washed with deionized water until neutral, oscillating at 160rpm at a constant temperature of 25°C for 30min, after cleaning, put the modified zeolite in an oven, dry at 105°C for 2h; roast at 450°C for 3h, and cool to At room temperature, wash with deionized water, filter, and dry at 105°C for 5 hours to obtain Na-type-acid-heat-treated modified zeolite with strong adsorption.

[0042] (2) Preparation of the middle layer adsorption material: inoculate phosphate solubilizing bacteria (purchased from Guangdong Institute of Microbiology) on hydroxyapatite (purchased from Shanghai Kanglang Biotechnology Co., Ltd., CAS number: 1306-06-5, heavy metal: ≤ 0.001%), mixed with the Na type-acid-heat-treated modified zeoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com