Oil product blending apparatus

A technology for oil products and blending tanks, applied in mixers, transportation, packaging, dissolution, etc., can solve problems such as static electricity, and achieve the effects of improving efficiency, increasing safety, and reducing static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

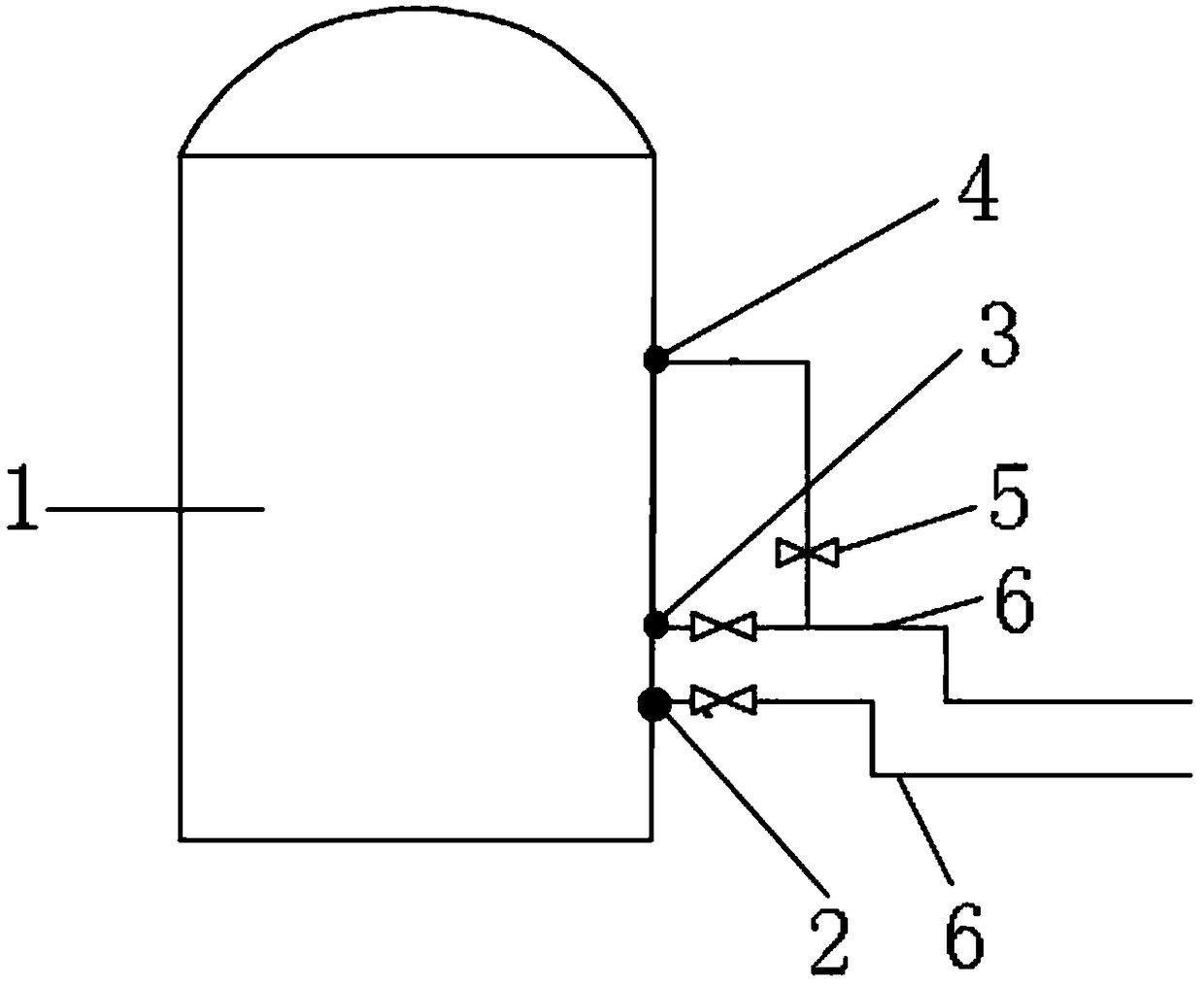

[0017] An oil blending device includes a blending tank (1), an oil outlet (2), a bottom feed port (3), a middle and upper feed port (4), a blending pipeline (6) and a valve (5 ). The oil outlet (2) is set at the bottom of the blending tank (1), the bottom feed port (3) is set at one-third of the height of the tank body, and the middle and upper feed port (4) is set at the bottom of the tank body height. two thirds. The oil outlet (2), the bottom feed port (3), and the middle and upper feed port (4) are respectively connected to the blending pipeline (6), and a valve (5) is installed on the blending pipeline (6). The blending pipelines (6) of the bottom feeding port (3) and the middle and upper feeding port (4) share one blending pipeline (6) after being controlled by the valve (5) to realize the same blending pipeline , the purpose of entering the tank at dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com