Road separation zone pruning machine

A technology of isolation belts and pruning machines, applied to agricultural machinery and tools, equipment for trimming hedges, cutting tools, etc., can solve the problems of waste of human resources, waste of manpower, and high noise, so as to reduce equipment operation noise and block noise The effect of the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

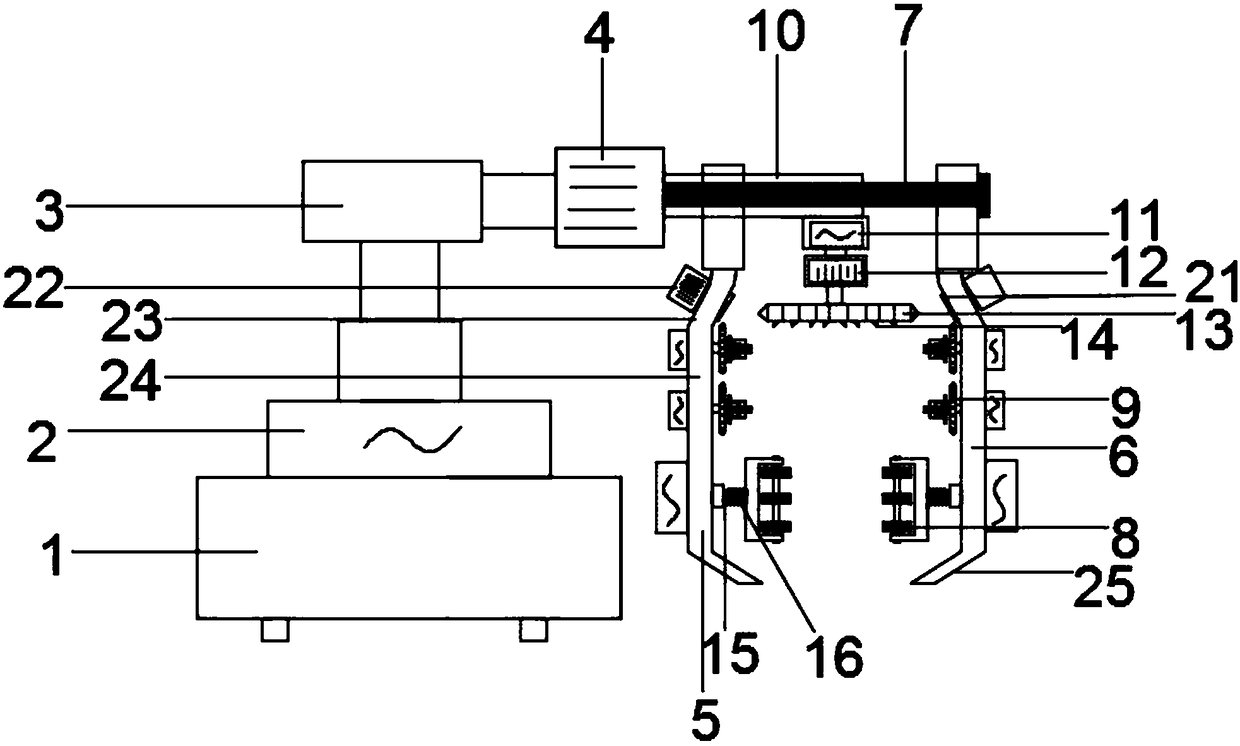

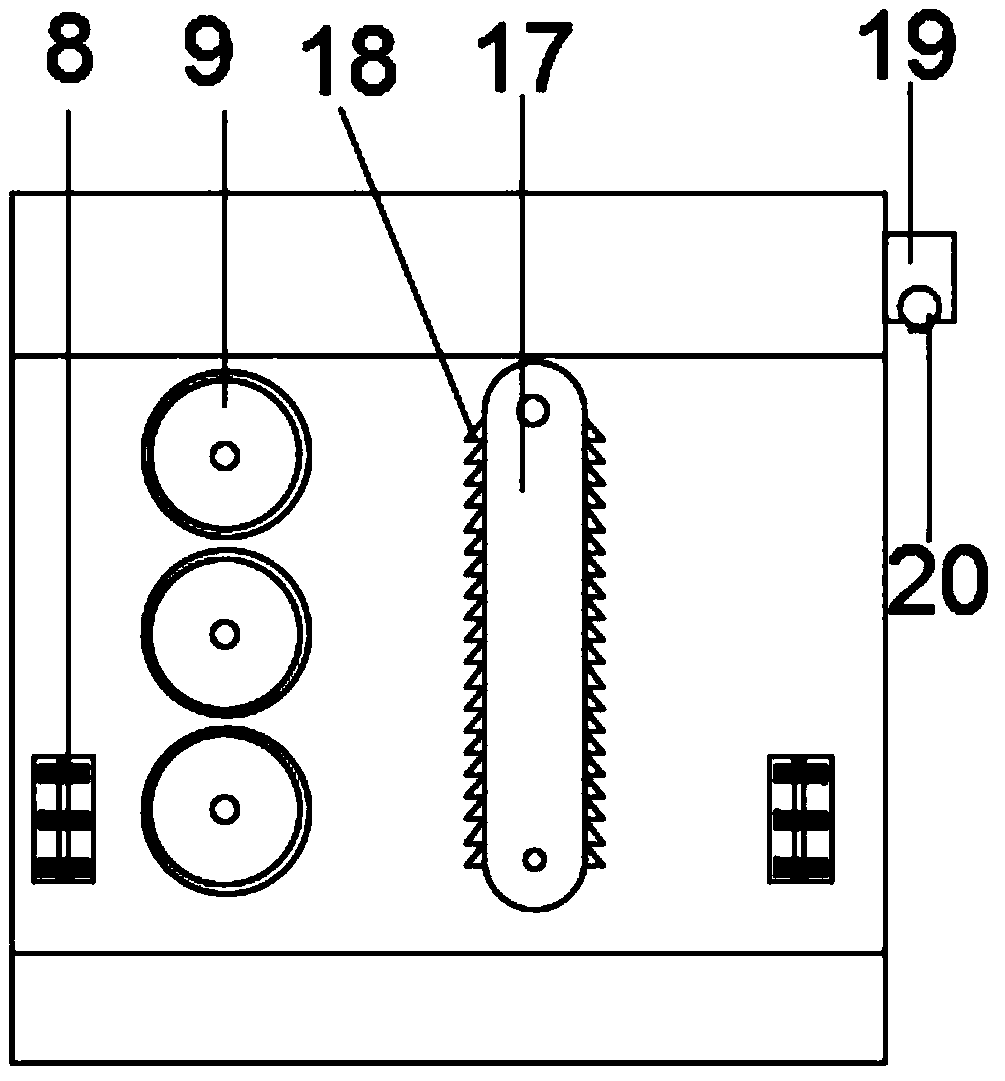

[0037] As a preferred embodiment, the vertical cutting knife sets 9 are three sets, and they are vertically located on the same straight line.

[0038] The advantage of setting like this is: the setting of multiple sets of cutting knife sets is to ensure that the working span of a single cutting single set will not be too large, and the single force borne is relatively small, which plays the role of protecting the cutting knife set 9 .

[0039] The principle (action process) of this device is: ① through the lifting cylinder 2, the entire equipment can be adjusted up and down to adapt to the isolation belts of different heights; Clamping of shrubs on the isolation belts of different widths; ③During operation, the carrier vehicle 1 moves forward slowly, and the shrubs are squeezed by the front side rollers 8 and contract inwardly; control the descending cylinder 11 to slowly lower the cutting disc 13, and through the cutting The cutting teeth 14 on the side of the disc 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com