Non-transfer arc plasma gun and plasma device with non-transfer arc plasma gun

A plasma gun and non-transferred arc technology, applied in the ion field, can solve the problems of high power supply and system requirements, complex structure design, high cost of use, etc., and achieve the effect of convenient hand-held operation, convenient operation, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

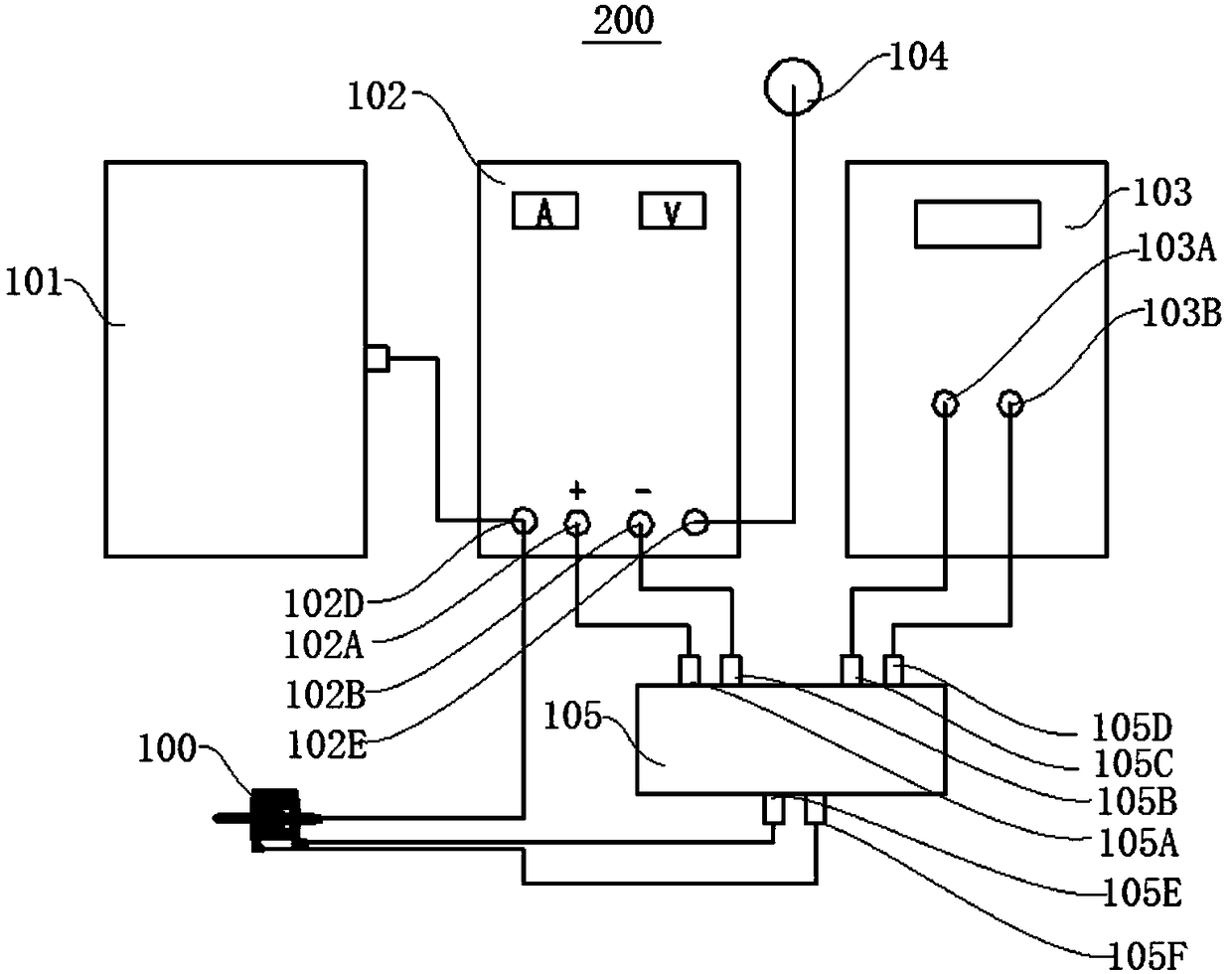

[0067] Such as figure 2 As shown, the plasma equipment 200 includes: an air compressor 101 , a plasma cutting machine power supply 102 , an arc ignition switch 104 , a chiller 103 , an adapter device 105 and a non-transferred arc plasma torch 100 .

[0068] The plasma cutting machine power supply 102 is provided with a positive electrode interface 102A, a negative electrode interface 102B, a gas interface 102D and an arc strike interface 102E. The chiller 103 is provided with a water outlet 103A and a water return port 103B. The switching device 105 is provided with a first interface 105A, a second interface 105B, a third interface 105C, a fourth interface 105D, a fifth interface 105E and a sixth interface 105F. Wherein, the air compressor 101 is connected with the gas interface 102D, and the gas interface 102D is connected with the intake pipe 2 . The positive interface 102A is connected to the first interface 105A, the negative interface 102B is connected to the second in...

Embodiment 2

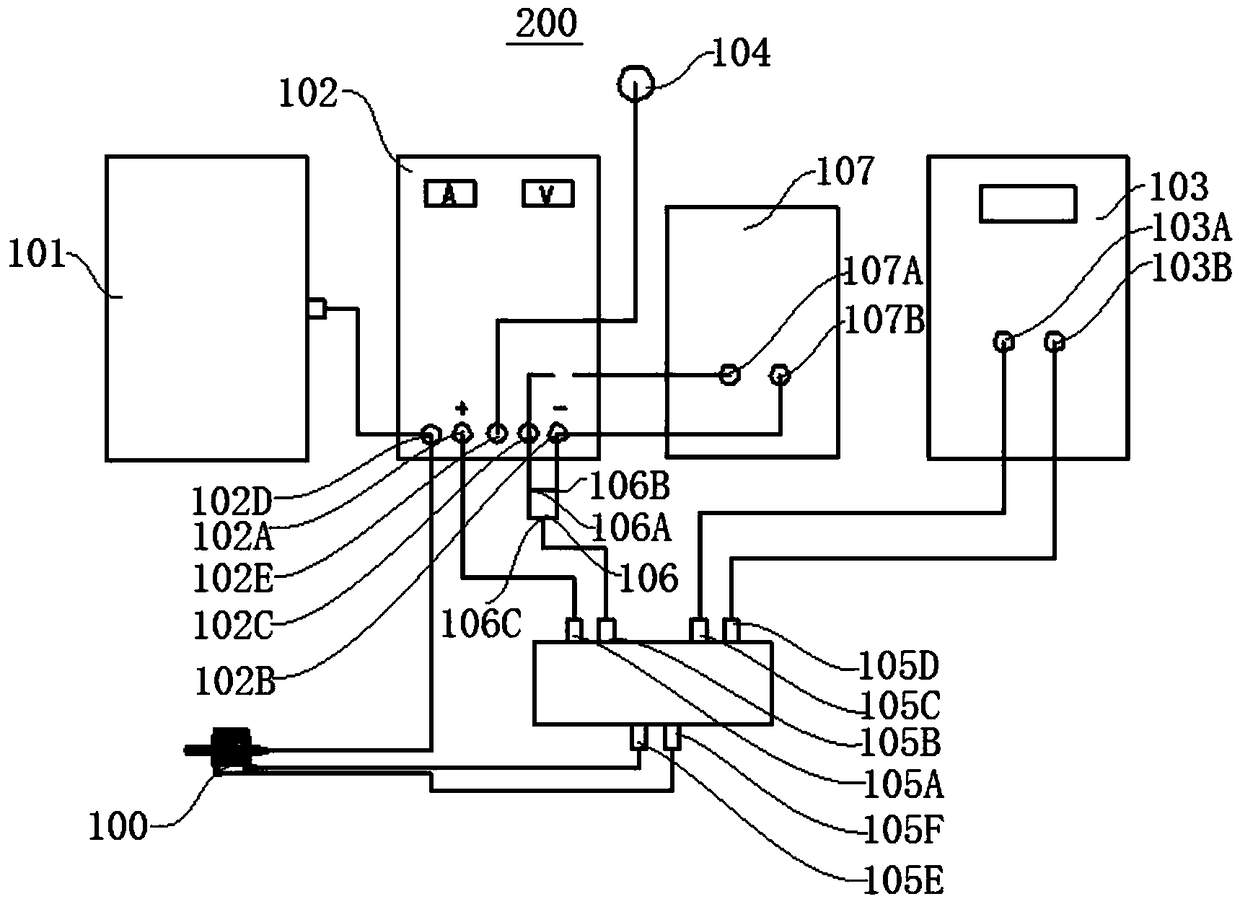

[0071] Such as image 3 As shown, the plasma equipment 200 includes: an air compressor 101 , a plasma cutter power supply 102 , an arc switch 104 , a water tank 107 , a chiller 103 , an adapter 105 , an adapter 106 and a non-transferred arc plasma torch 100 .

[0072] The plasma cutting machine power supply 102 is provided with a positive electrode interface 102A, a negative electrode interface 102B, a water and electricity interface 102C, a gas interface 102D and an arc starting interface 102E. The adapter device 105 is provided with a first interface 105A, a second interface 105B, a third interface 105C, a fourth interface 105D, a fifth interface 105E and a sixth interface 105F, and the water tank 107 is provided with an inlet 107A and an outlet 107B. 103 is provided with a water outlet 103A and a water return port 103B. One end of the adapter device 105 is provided with an adapter 106 , and the adapter 106 is provided with a first port 106A, a second port 106B and a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com