Bio-organic fertilizer fermentation preparation

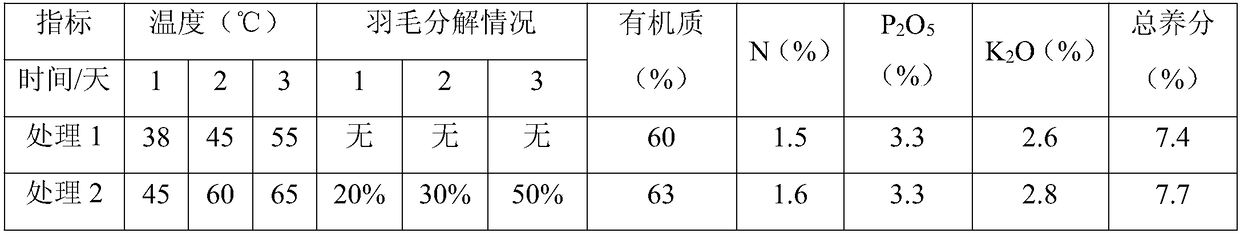

A bio-organic fertilizer and fermentation agent technology, applied in the field of bio-organic fertilizer fermentation agents, can solve the problems that poultry manure and poultry feathers cannot be fermented synchronously, cannot complete the fermentation and transformation of poultry feathers, and the poultry feathers are not fully utilized, etc. Pathogenic microorganisms, less total nutrient loss in compost, and the effect of solving production difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The bio-organic fertilizer fermenting agent of the present invention, its active component comprises following bacterial species: preservation number is Bacillus amyloliquefaciens K1 of CICC.NO.10888, preservation number is Bacillus subtilis D1 of preservation number CICC.NO.10073, preservation number is Bacillus subtilis D2 with CICC.NO.10090, Bacillus licheniformis S1 with preservation number CICC.NO.10037, Bacillus licheniformis S2 with preservation number CICC.NO.10092, thermophile with preservation number ACCC.NO.30346 Sporotrichum T1.

[0037] The preparation method of seed bacterial agent of the present invention is:

[0038] 1) Inoculate Bacillus amyloliquefaciens K1 in medium I with a pH of 7.0 prepared with 3 g of peptone, 2 g of beef extract, 3 g of NaCl, 10 g of agar, and 0.8 L of distilled water, and culture on a shaking table at 35°C 1 day, the shaking speed was 100rpm, and the Bacillus amyloliquefaciens seed agent N1 was obtained;

[0039] 2) Inoculate ...

Embodiment 2

[0048] The bio-organic fertilizer fermenting agent of the present invention, its active component comprises following bacterial species: preservation number is Bacillus amyloliquefaciens K1 of CICC.NO.10888, preservation number is Bacillus subtilis D1 of preservation number CICC.NO.10073, preservation number is Bacillus subtilis D2 with CICC.NO.10090, Bacillus licheniformis S1 with preservation number CICC.NO.10037, Bacillus licheniformis S2 with preservation number CICC.NO.10092, thermophile with preservation number ACCC.NO.30346 Sporotrichum T1.

[0049] The preparation method of seed bacterial agent of the present invention is:

[0050] 1) Inoculate Bacillus amyloliquefaciens K1 in medium I with a pH of 7.0 prepared with 4 g of peptone, 3 g of beef extract, 4 g of NaCl, 12 g of agar, and 0.9 L of distilled water, and culture on a shaking table at 36°C For 2 days, the shaking speed was 120rpm, and Bacillus amyloliquefaciens seed agent N1 was obtained;

[0051] 2) Inoculate...

Embodiment 3

[0061] The bio-organic fertilizer fermenting agent of the present invention, its active component comprises following bacterial species: preservation number is Bacillus amyloliquefaciens K1 of CICC.NO.10888, preservation number is Bacillus subtilis D1 of preservation number CICC.NO.10073, preservation number is Bacillus subtilis D2 with CICC.NO.10090, Bacillus licheniformis S1 with preservation number CICC.NO.10037, Bacillus licheniformis S2 with preservation number CICC.NO.10092, thermophile with preservation number ACCC.NO.30346 Sporotrichum T1.

[0062] The preparation method of seed bacterial agent of the present invention is:

[0063] 1) Inoculate Bacillus amyloliquefaciens K1 in medium I with a pH of 7.0 prepared with 5 g of peptone, 4 g of beef extract, 5 g of NaCl, 14 g of agar, and 1 L of distilled water, and culture it on a shaking table at 37°C for 3 days, the shaking speed was 140rpm, and the Bacillus amyloliquefaciens seed agent N1 was obtained;

[0064] 2) Inoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com