Method for preparing polyacrylate Pickering emulsion

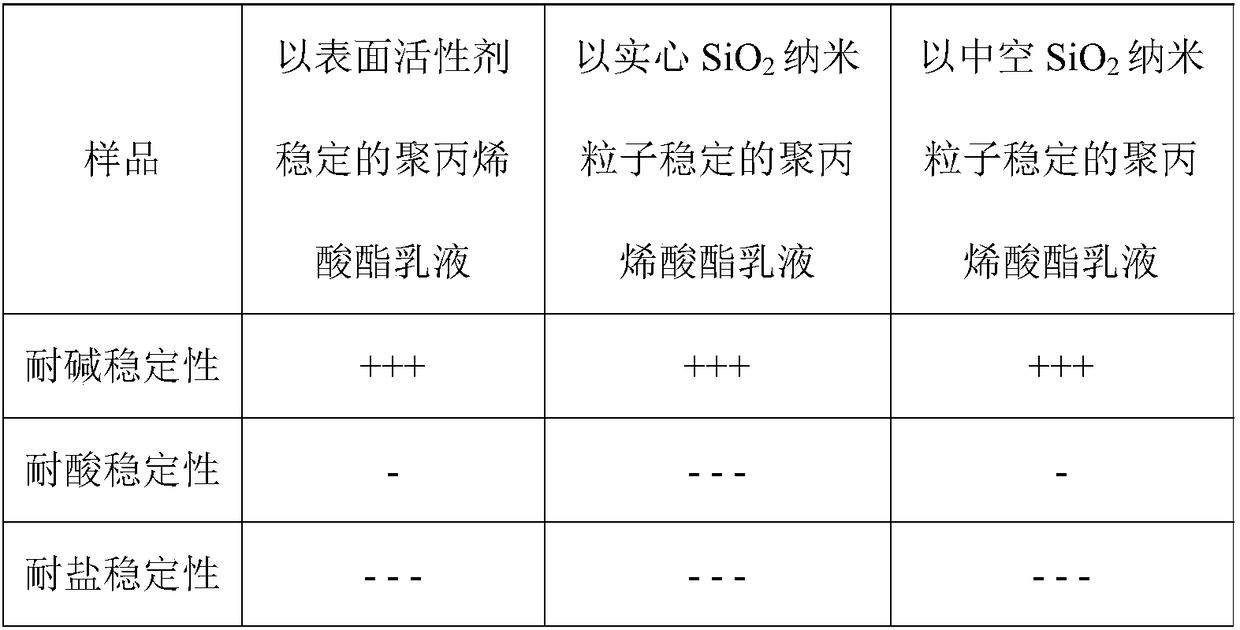

A technology of polyacrylate emulsion and polyacrylate, applied in the field of emulsion preparation, can solve the problems of surfactant toxicity, decrease in stability and mechanical properties, poor water resistance of film, etc., and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

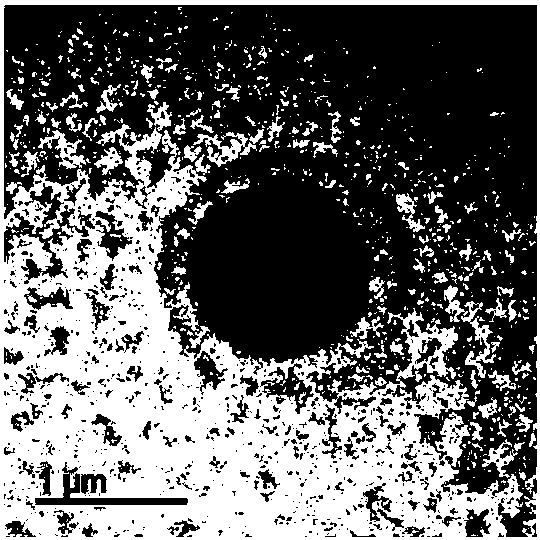

[0028] (1) Hollow SiO 2 Modification of Nanoparticles

[0029] 30nm hollow SiO 2 Add nanoparticles into 80mL of absolute ethanol, disperse evenly by ultrasonication at 40W for 20min, heat up to 55°C, add hydrophobic modifier, keep warm for 2h, wash and dry to obtain modified hollow SiO 2 Nanoparticles;

[0030] Among them, the hollow SiO 2 The mass ratio of the nanoparticles to the hydrophobic modifier is 1.5g:0.06g, and the hydrophobic modifier is hexamethyldisilazane.

[0031] (2) Preparation of polyacrylate Pickering emulsion

[0032] ammonium persulfate and modified hollow SiO 2 The nanoparticles are added into water, and then methyl methacrylate, butyl acrylate and acrylic acid are added, the temperature is raised to 50° C., and the reaction is kept for 0.5 h to prepare the seeds of the polyacrylate emulsion. Among them, methyl methacrylate, butyl acrylate, acrylic acid, modified hollow SiO 2 The mass ratio of nanoparticles, ammonium persulfate and water is 0.529g:...

Embodiment 2

[0037] (1) Hollow SiO 2 Modification of Nanoparticles

[0038] 50nm hollow SiO 2 Nanoparticles were added to 80mL of absolute ethanol, dispersed evenly by ultrasonication at 60W for 15min, heated to 60°C, added hexamethyldisilazane, kept for 4h, washed and dried to obtain modified hollow SiO 2 nanoparticles; among them, hollow SiO2 The mass ratio of nanoparticles to hexamethyldisilazane is 1.7g:0.08g.

[0039] (2) Preparation of polyacrylate Pickering emulsion

[0040] ammonium persulfate and modified hollow SiO 2 The nanoparticles are added into water, and then methyl methacrylate, butyl acrylate and acrylic acid are added, the temperature is raised to 55° C., and the reaction is kept for 0.5 h to prepare the seeds of the polyacrylate emulsion. Among them, methyl methacrylate, butyl acrylate, acrylic acid, modified hollow SiO 2 The mass ratio of nanoparticles, ammonium persulfate and water is 0.529g: 1.462g: 0.060g: 0.041g: 0.065g: 30g;

[0041] Then the temperature was...

Embodiment 3

[0045] (1) Hollow SiO 2 Modification of Nanoparticles

[0046] 100nm hollow SiO 2 Nanoparticles were added to 90mL of absolute ethanol, sonicated at 80W for 10min to disperse uniformly, heated to 65°C, added trimethylchlorosilane, kept for 5h, washed and dried to obtain modified hollow SiO 2 nanoparticles; among them, hollow SiO 2 The mass ratio of nanoparticles to trimethylchlorosilane is 2.0g:0.10g.

[0047] (2) Preparation of polyacrylate Pickering emulsion

[0048] ammonium persulfate and modified hollow SiO 2 The nanoparticles were added into water, and then methyl methacrylate, butyl acrylate and acrylic acid were added, the temperature was raised to 60° C., and the reaction was kept for 40 minutes to prepare the seeds of the polyacrylate emulsion. Among them, methyl methacrylate, butyl acrylate, acrylic acid, modified hollow SiO 2 The mass ratio of nanoparticles, ammonium persulfate and water is 0.521g: 1.444g: 0.059g: 0.051g: 0.064g: 30g;

[0049] Then the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com