Cutting energy-absorbing mechanism for passenger car

A passenger car and fixed sleeve technology, which is applied to steering mechanism, steering control mounted on the car, vehicle components, etc., can solve the problems of insufficient connection rigidity, discomfort, excessive deformation, etc., and achieve the effect of stable energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

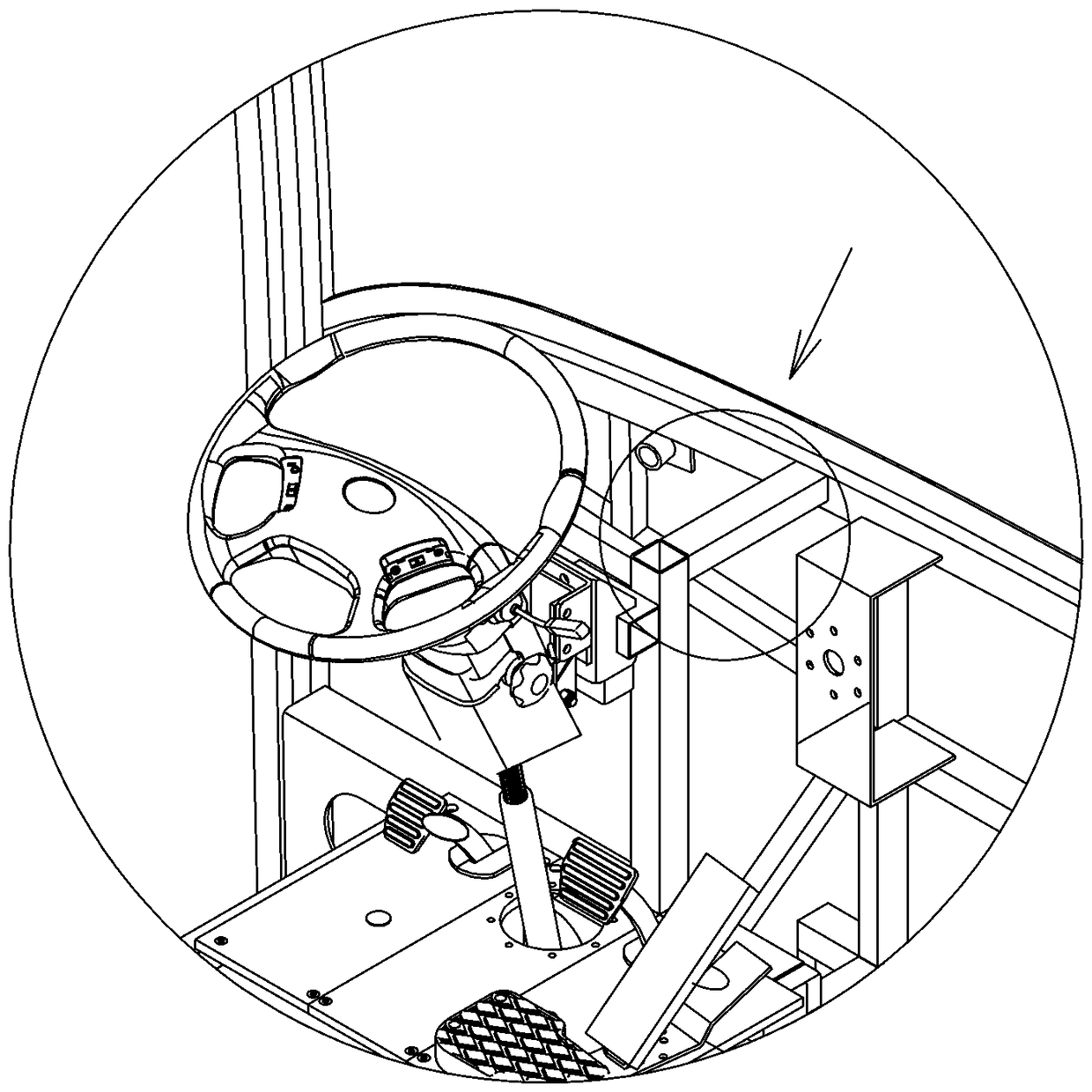

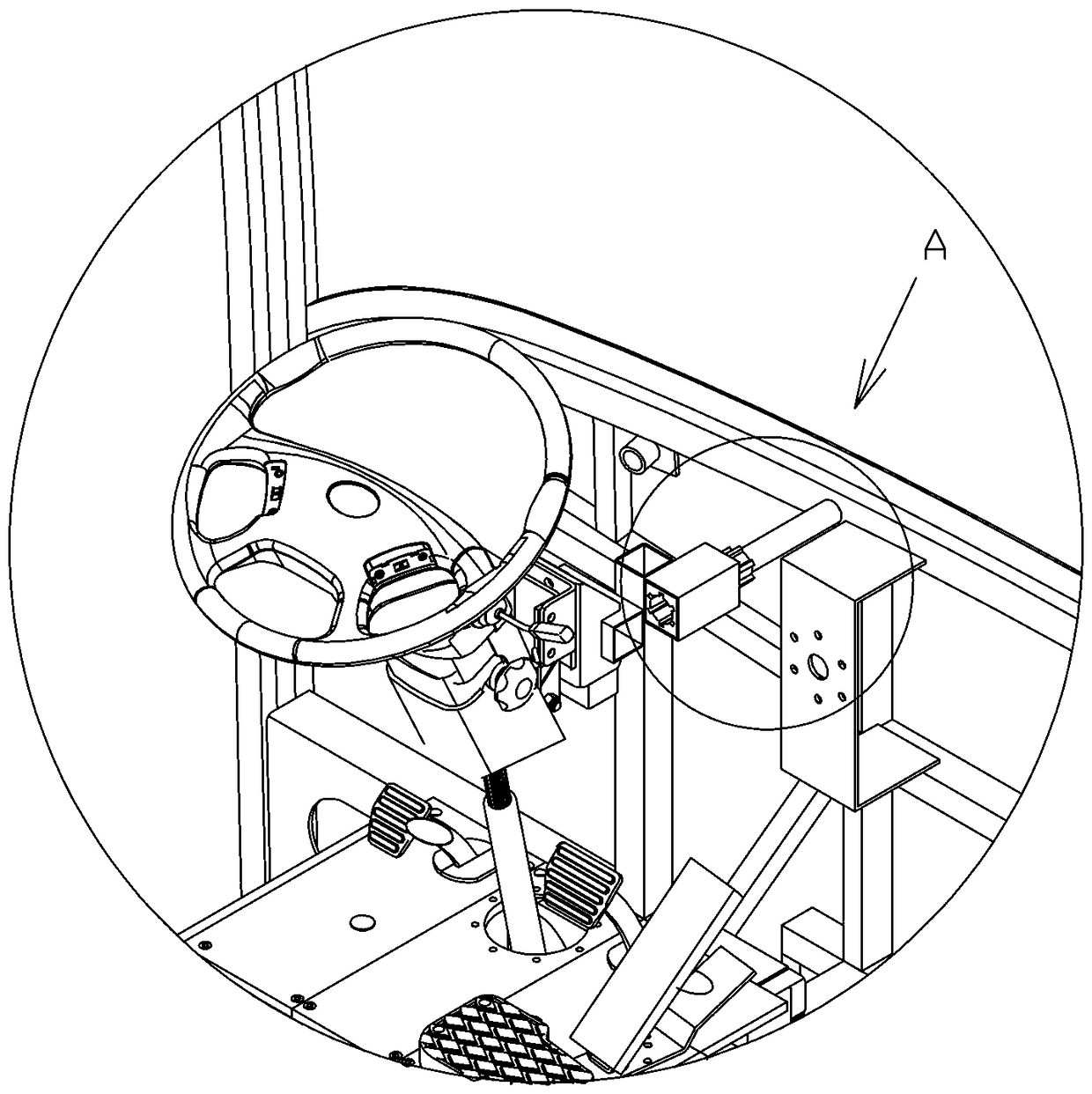

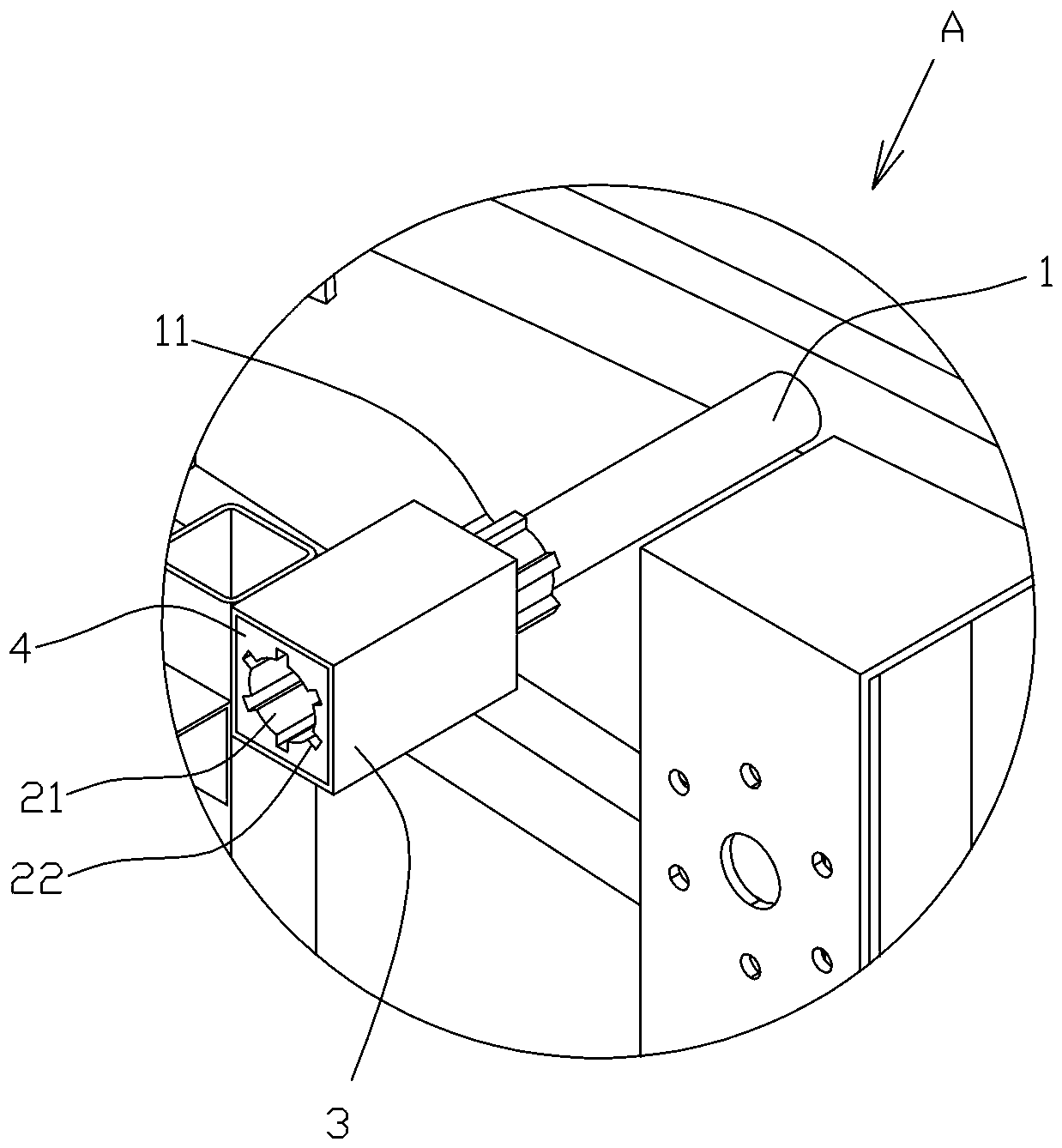

[0026] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

[0027] Such as Figure 2 to Figure 6 As shown, a cutting energy-absorbing mechanism for a passenger car includes a spline shaft 1, a spline sleeve 2, a fixed sleeve 3 and a baffle plate 4, and the spline shaft 1 is installed on the In the spline sleeve 2, the spline sleeve 2 is movably nested in the fixed sleeve 3, the baffle plate 4 is fixedly installed at the tail end of the fixed sleeve 2, and the spline shaft 1 The tail end of the bus is fixedly connected with the dash rod of the passenger car, and the fixed sleeve 3 is fixedly connected with the column of the steering platform of the passenger car.

[0028] Further, the front end of the spline shaft 1 is evenly arranged with several cutting bits 11 along its peripheral edge, and a spline channel 21 is provided in the spline sleeve 2 along its axial direction, and the periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com