Grinding-head upper mechanism for ceramic polishing machine

A ceramic polishing machine and grinding head technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of unfavorable workpiece quality, large friction coefficient, and slow running speed, etc. It achieves the effects of convenient inspection and maintenance, small friction coefficient and high limit speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

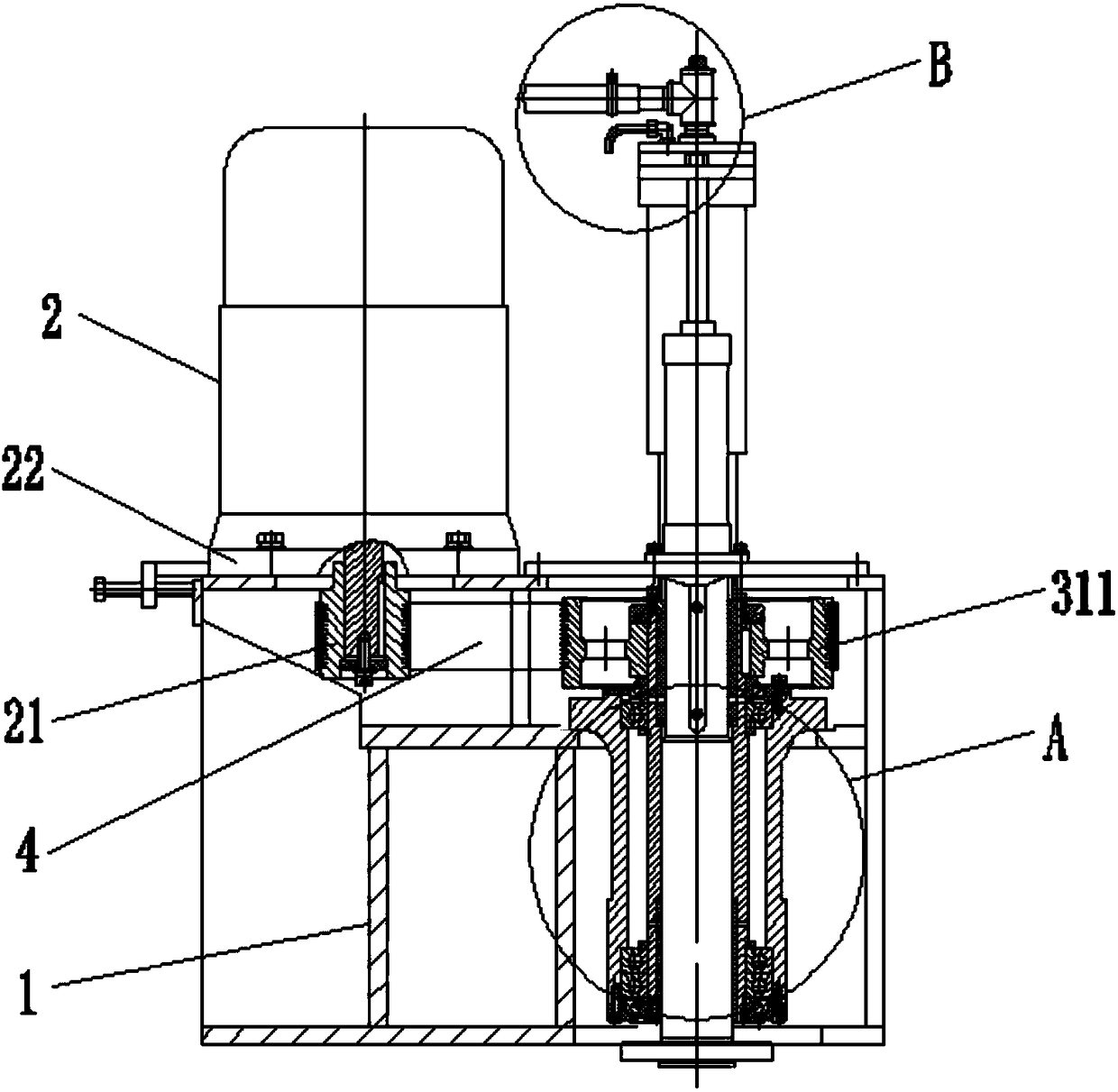

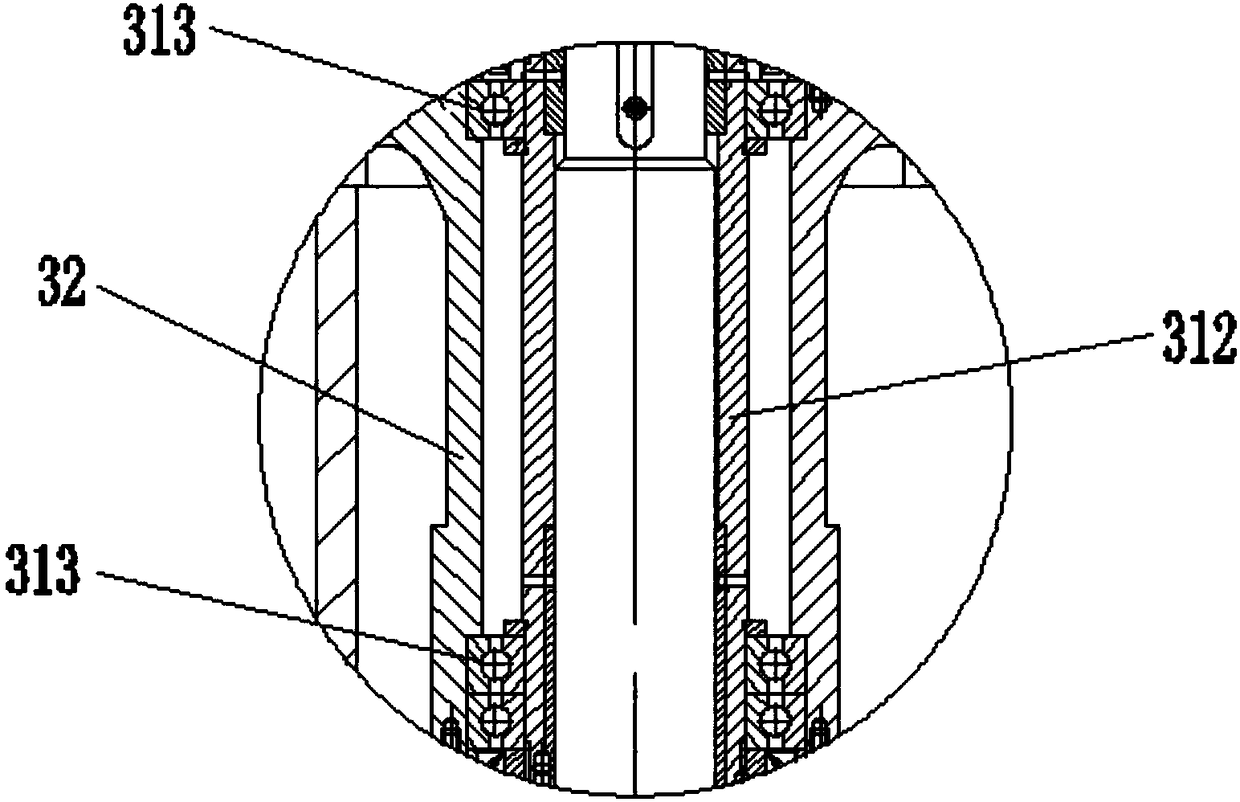

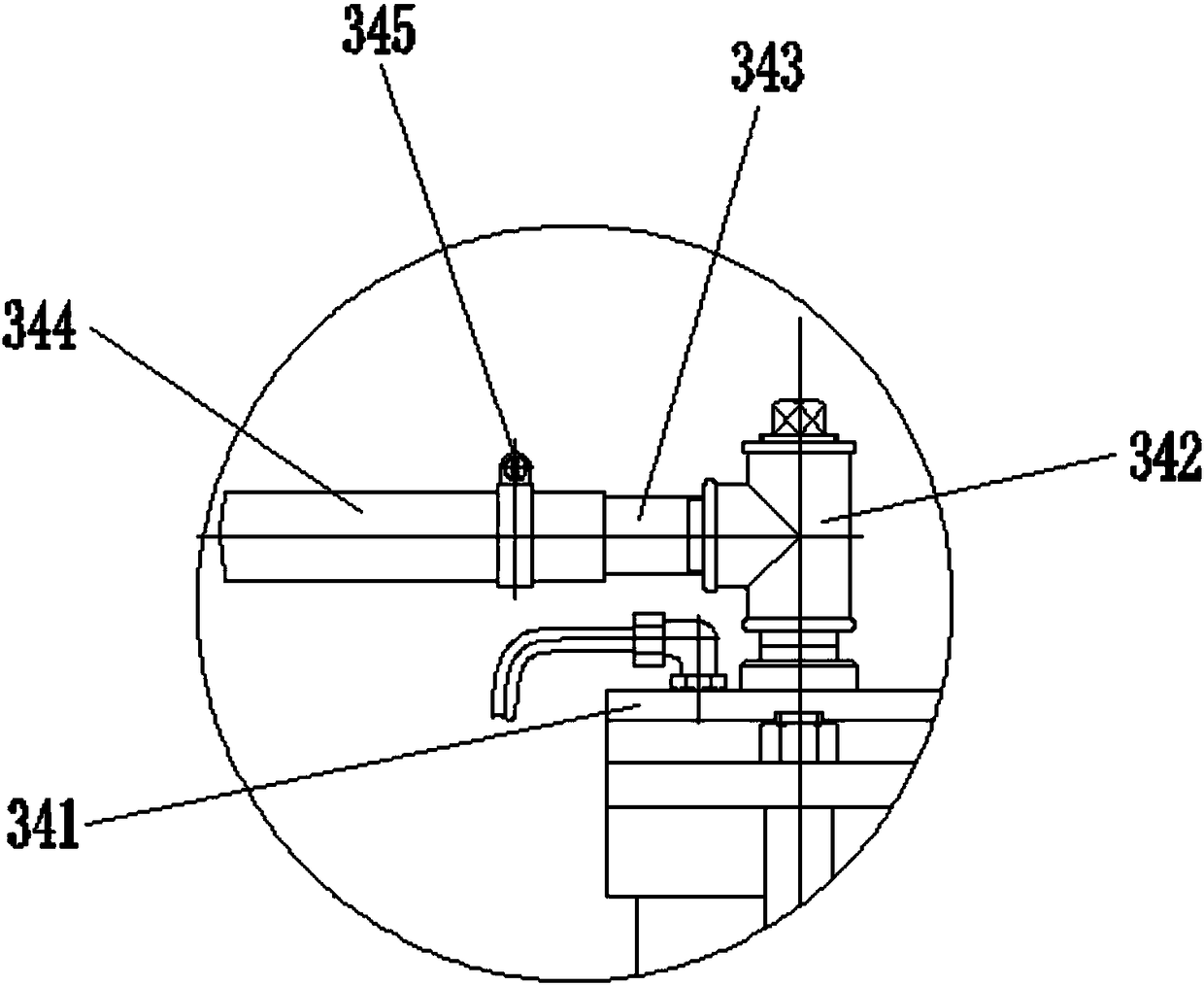

[0024] Such as Figure 1-Figure 6 As shown, the present invention is used for the upper mechanism of the grinding head of the ceramic polishing machine including frame 1, motor 2 and grinding head upper assembly 3, wherein:

[0025] Both the motor 2 and the grinding head upper assembly 3 are arranged on the frame 1, and a vibration-damping pad 22 is arranged between the motor 2 and the frame 1. The vibration-damping pad 22 includes a rubber vibration-damping plate 221 and is arranged in the rubber vibration-damping plate 221. The spring 222, the spring 222 is equally spaced and evenly distributed in the rubber damping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com