Method adopting robot for automatic recognition and additive forming of uneven surface

A technology of additive forming and robotics, which is applied in the fields of machine vision and additive forming, can solve problems such as lack of perception ability and scheduled task failure, and achieve the effects of high flexibility, easy operation and wide field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention more clear and definite, the present invention will be further stated below in conjunction with the accompanying drawings and specific embodiments.

[0034] The following examples serve to illustrate the invention, but do not limit the invention.

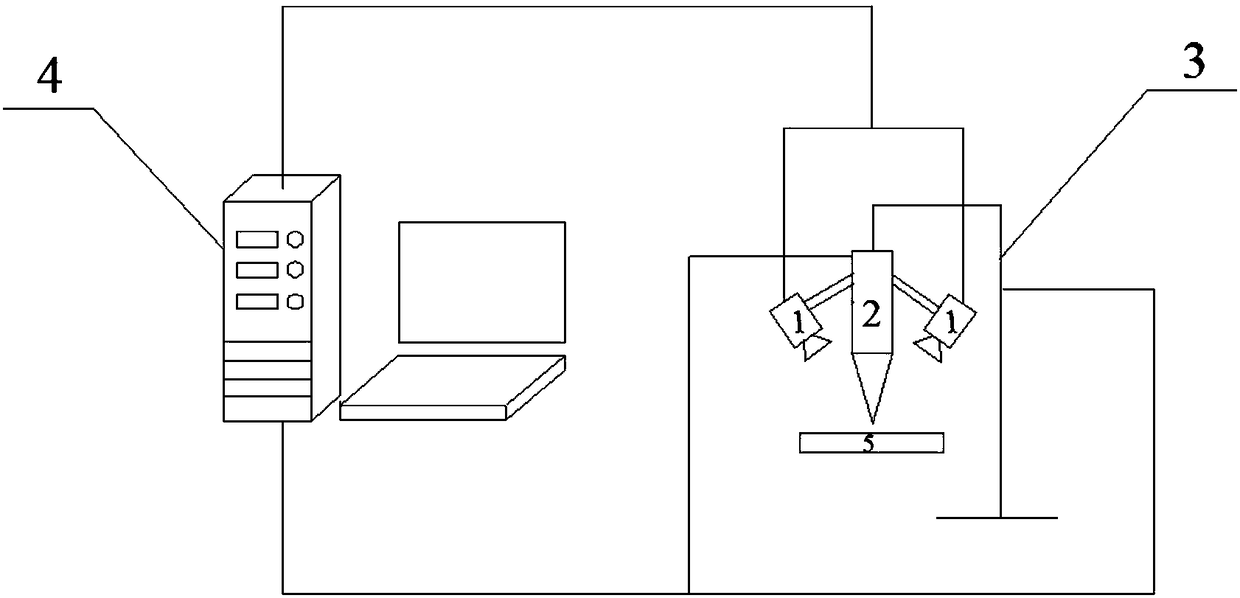

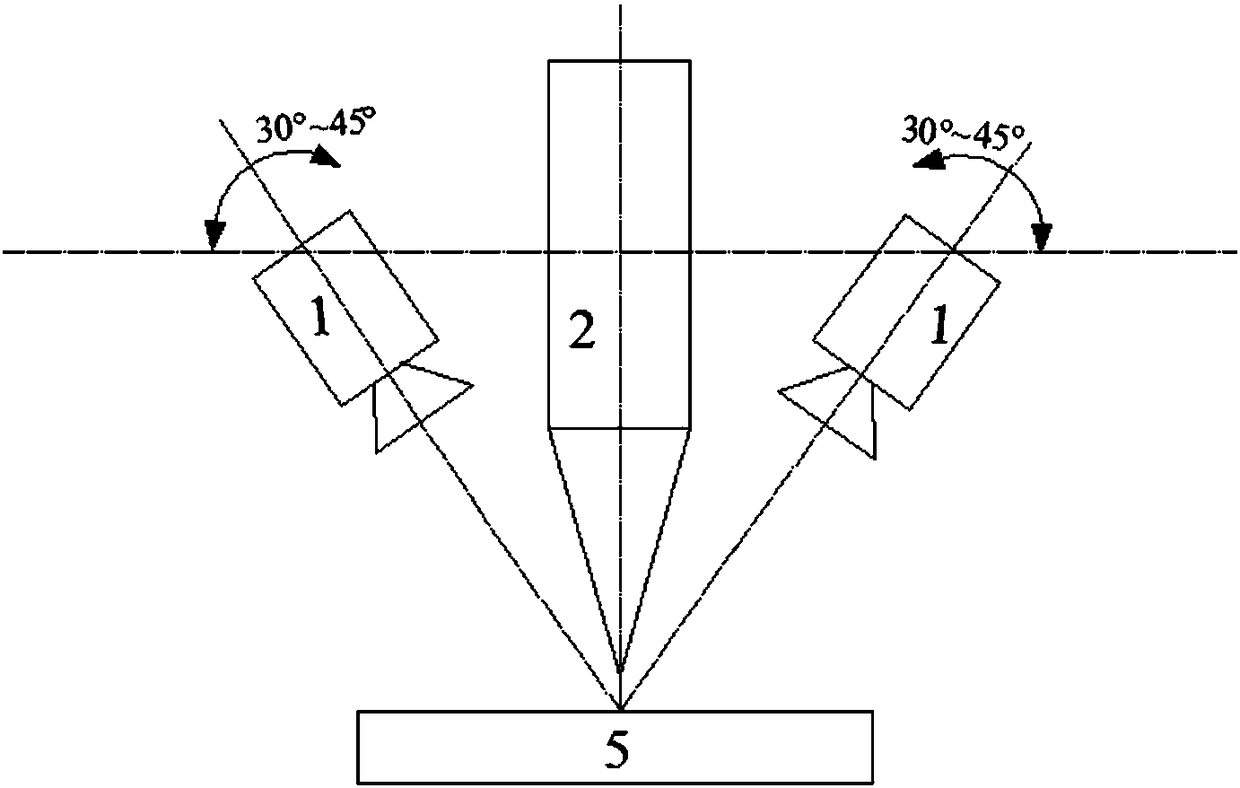

[0035] Such as figure 1 As shown, the device of the present invention based on the method of autonomous recognition of non-flat surfaces by robots for adding materials mainly includes: two left and right CCD cameras 1, an additive gun 2, a six-axis robot 3, a controller 4, and a workpiece 5 to be added. Among them, the two left and right CCD cameras 1 are fixed on both sides of the additive gun 2 with fixtures at an angle of 30° to 45° between the normal of the lens end face and the normal of the workpiece surface, and the additive gun 2 is installed at the end of the six-axis robot. The controller 4 is connected to the two left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com