Numerical control machine tool for machining short shaft

A technology of CNC machine tools and short shafts, which is applied in metal processing equipment, manufacturing tools, accessories of toolholders, etc., can solve the problems of inability to improve conveying efficiency, difficult to use manipulators, and occupy a large space, and achieves simple structure and conveying distance. Short, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

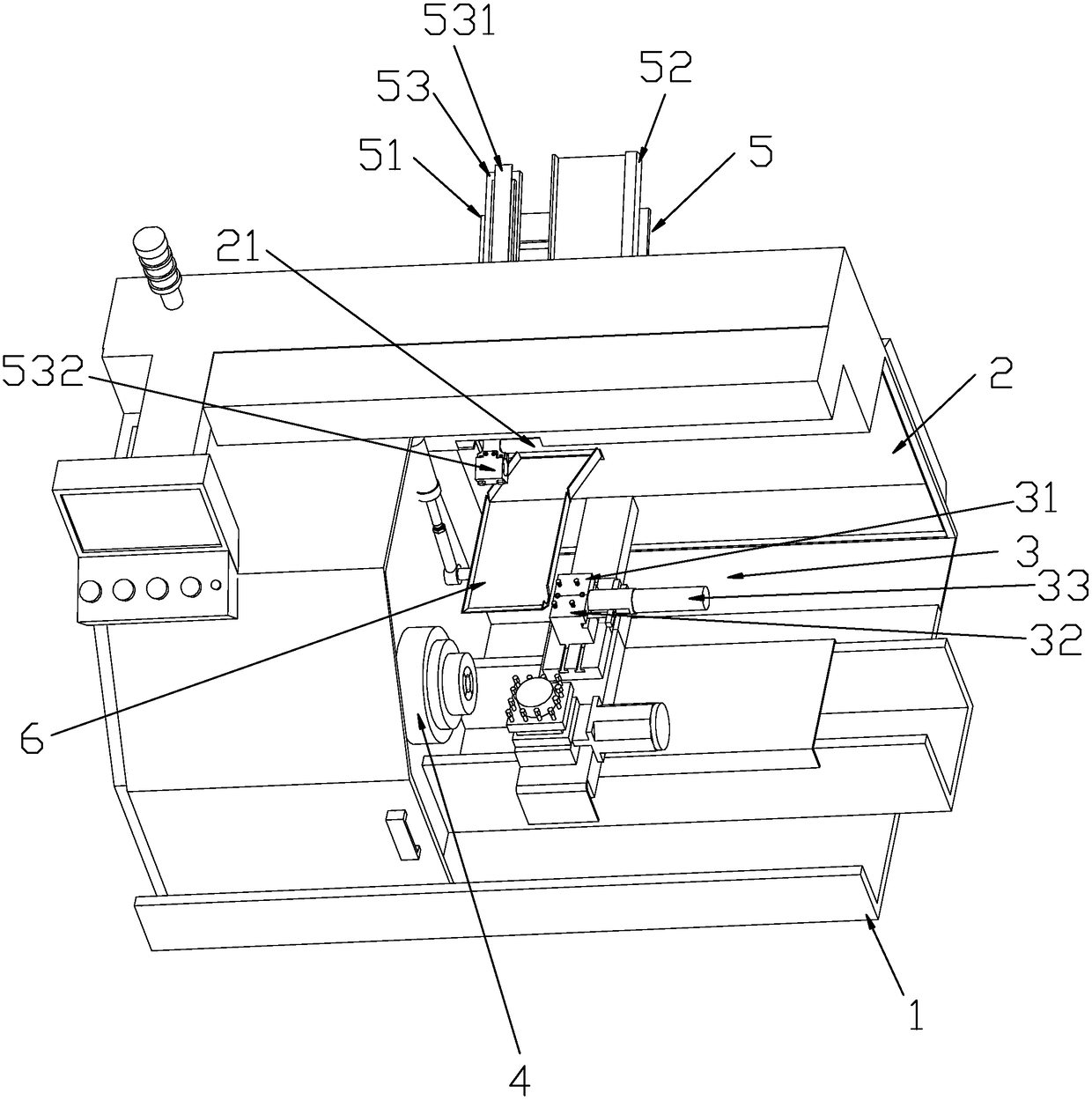

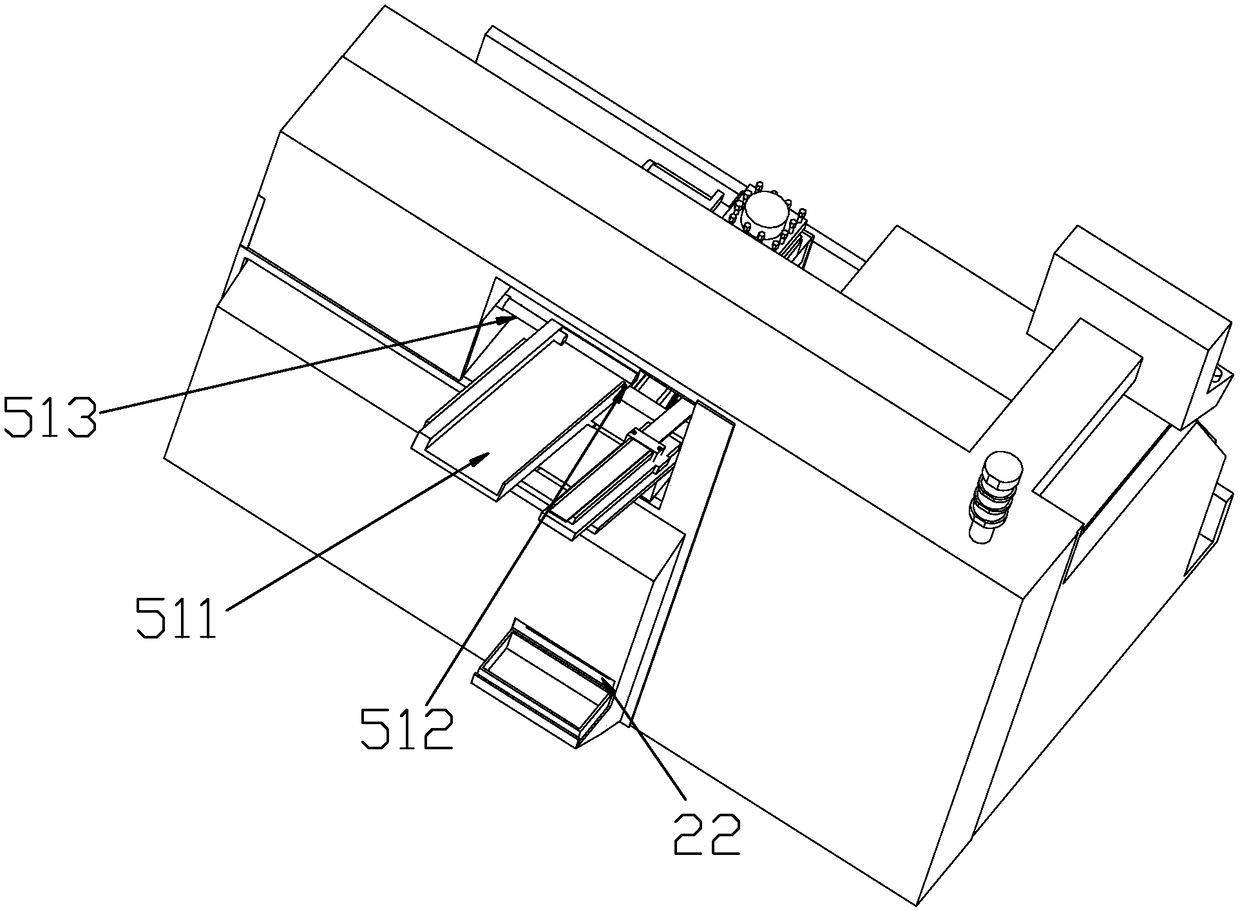

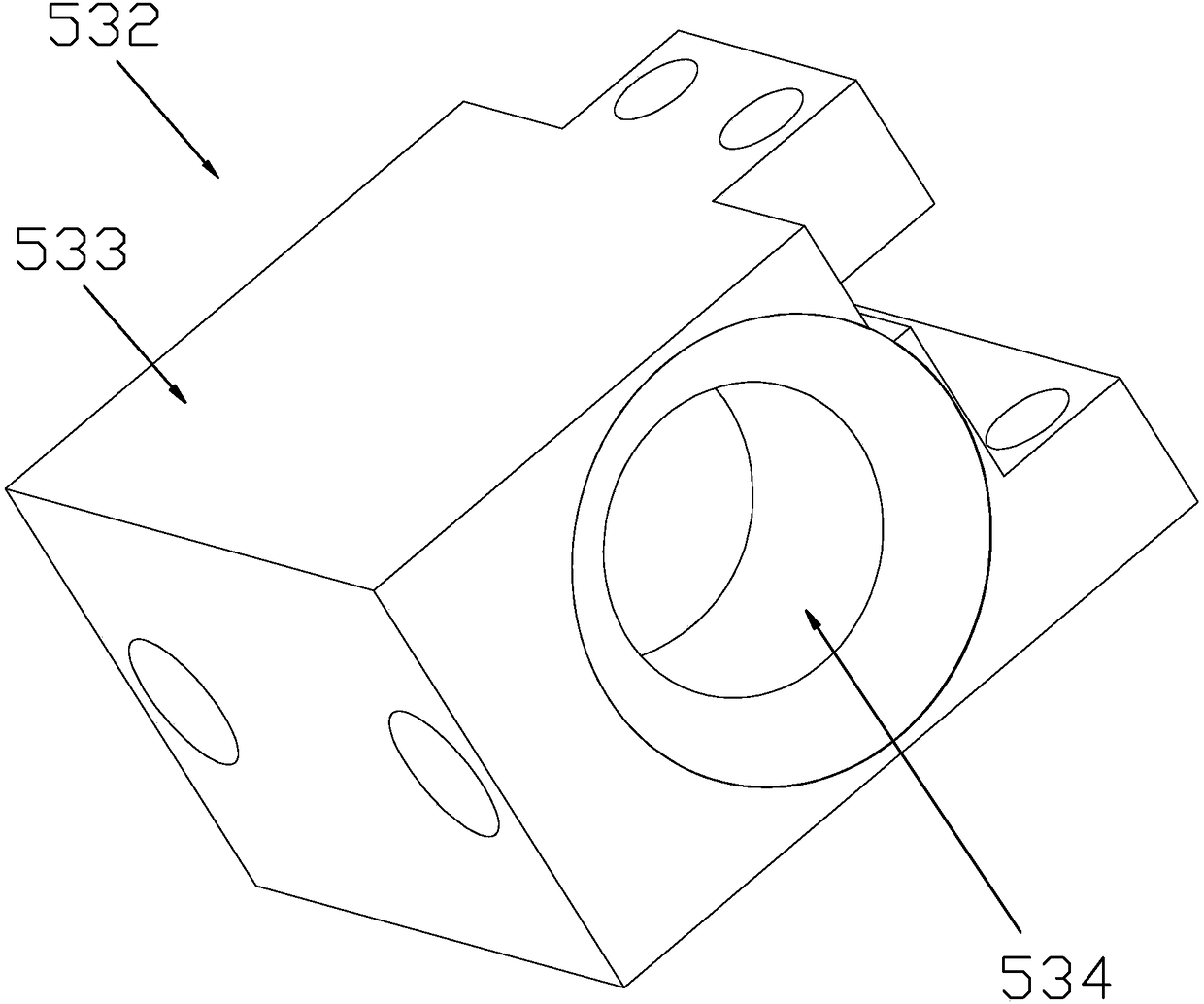

[0023] see Figure 1-Figure 4 As shown: a CNC machine tool for machining short shafts, including a CNC machine tool body 1, a baffle plate 2 is provided on the periphery of the CNC machine tool body 1, and a clamping station for clamping the short shaft is provided on the CNC machine tool body 1 3. The clamping station 3 includes a first clamping part 31 for clamping the short shaft before processing and a second clamping part 32 for clamping the processed short shaft. One side of the position 3 is provided with a processing station 4 for processing the short shaft on the clamping station 3, and the end of the first clamping part and the second clamping part away from the processing station is provided with a driving first clamping part And the driving cylinder 33 of the second clamping part, the top of the baffle plate 2 is provided with a conveying station 5 that reciprocates up and down along the plane where the vertical clamping station 3 is located between the clamping st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com