Preparation method of double-layer hollow fibrous nanofiltration membrane

A double-layer hollow nanofiltration membrane technology, which is applied in the field of membrane separation, can solve the problems of low yield of nanofiltration membranes, complicated preparation methods, and many factors affecting the process, so as to achieve uniform and stable membrane layers, good separation performance, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

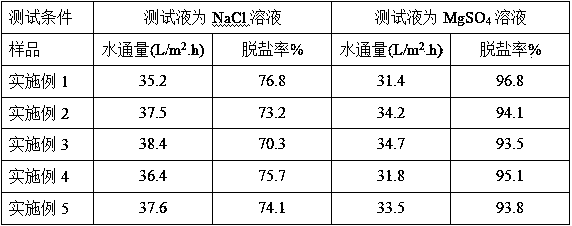

Examples

Embodiment 1

[0016] (1) Mix and stir the high molecular polymer a, organic solvent and dispersant according to the mass ratio of 10%: 45%: 45% to form a uniform and stable casting solution A, and remove the bubbles in the casting solution by vacuum suction ,stand-by.

[0017] (2) Mix and stir the high molecular polymer b, organic solvent and dispersant according to the mass ratio of 20%: 50%: 30% to form a uniform and stable casting solution B, and remove the bubbles in the casting solution by vacuum suction ,stand-by.

[0018] (3) The casting solution A and the casting solution B are ejected through the double-hole spinneret under the pressure drive at the same time. The driving pressure of the casting solution A is 0.05MPa, and the driving pressure of the casting solution B is 0.2MPa. The liquid flow rate is 20ml / min, the air section distance is 10cm, and the spun membrane filaments are formed in the outer gel bath water to obtain a double-layer hollow fiber nanofiltration membrane.

Embodiment 2

[0020] (1) Mix and stir the high molecular polymer a, organic solvent and dispersant according to the mass ratio of 10%: 45%: 45% to form a uniform and stable casting solution A, and remove the bubbles in the casting solution by vacuum suction ,stand-by.

[0021] (2) Mix and stir the high molecular polymer b, organic solvent and dispersant according to the mass ratio of 25%: 50%: 25% to form a uniform and stable casting solution B, and remove the bubbles in the casting solution by vacuum suction ,stand-by.

[0022] (3) The casting solution A and the casting solution B are ejected through the double-hole spinneret under the pressure drive at the same time. The driving pressure of the casting solution A is 0.05MPa, and the driving pressure of the casting solution B is 0.2MPa. The liquid flow rate is 20ml / min, the air section distance is 10cm, and the spun membrane filaments are formed in the outer gel bath water to obtain a double-layer hollow fiber nanofiltration membrane.

Embodiment 3

[0024] (1) Mix and stir the high molecular polymer a, organic solvent and dispersant according to the mass ratio of 10%: 45%: 45% to form a uniform and stable casting solution A, and remove the bubbles in the casting solution by vacuum suction ,stand-by.

[0025] (2) Mix and stir the high molecular polymer b, organic solvent and dispersant according to the mass ratio of 30%: 50%: 20% to form a uniform and stable casting solution B, and remove the bubbles in the casting solution by vacuum suction ,stand-by.

[0026] (3) The casting solution A and the casting solution B are ejected through the double-hole spinneret under the pressure drive at the same time. The driving pressure of the casting solution A is 0.05MPa, and the driving pressure of the casting solution B is 0.2MPa. The liquid flow rate is 20ml / min, the air section distance is 10cm, and the spun membrane filaments are formed in the outer gel bath water to obtain a double-layer hollow fiber nanofiltration membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com