Phi 20*35 aluminum-shelled high ripple-resistant electrolytic capacitor

A technology of electrolytic capacitors and aluminum shells, applied in capacitor electrodes, capacitor dielectric layers, capacitor parts, etc., can solve the problem of using conditions and various properties that fail to meet customer-specific requirements, does not meet actual use requirements, and electrochemical performance. General and other problems, to achieve the effect of excellent electrochemical performance, reasonable overall structure setting and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

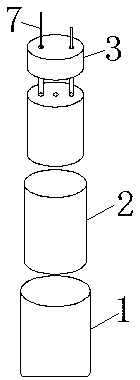

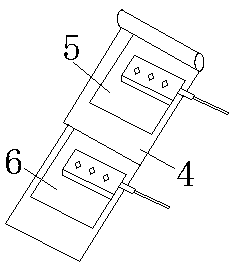

[0015] like figure 1 and figure 2 As shown, the high-ripple-resistant electrolytic capacitor with a φ20×35 aluminum shell of the present invention includes a rubber tube 1, and an aluminum shell 2 of φ20×35 is arranged in the rubber tube 1, and a A core pack, colloidal particles 3 are arranged above the core pack, the core pack includes electrolytic paper 4, and a positive foil 5 and a negative foil 6 arranged on the electrolytic paper 4, in which the positive foil 5 and the negative foil 6 There are guide pins 7 on them, the height ratio between the core package and the rubber particles 3 is (3.2-4.2): 1, and the width ratio between the positive foil 5 and the electrolytic paper 4 is (0.78-0.85): 1, so The width ratio of the negative foil 6 to the electrolytic paper 4 is (0.78-0.85): 1, the width of the positive foil 5 and the negative foil 6 are th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com