Hole sealing device used for deep coal gas extraction and capable of sealing boreholes twice, injecting once and exhausting once and application method

A technology for coal seam gas extraction and drilling, which is used in gas discharge, safety devices, mining equipment, etc., can solve the problems of easy formation of air pockets, hindering grouting by grouting pumps, and reducing the effective plugging length. Slurry pressure, improve pumping concentration, improve the effect of sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

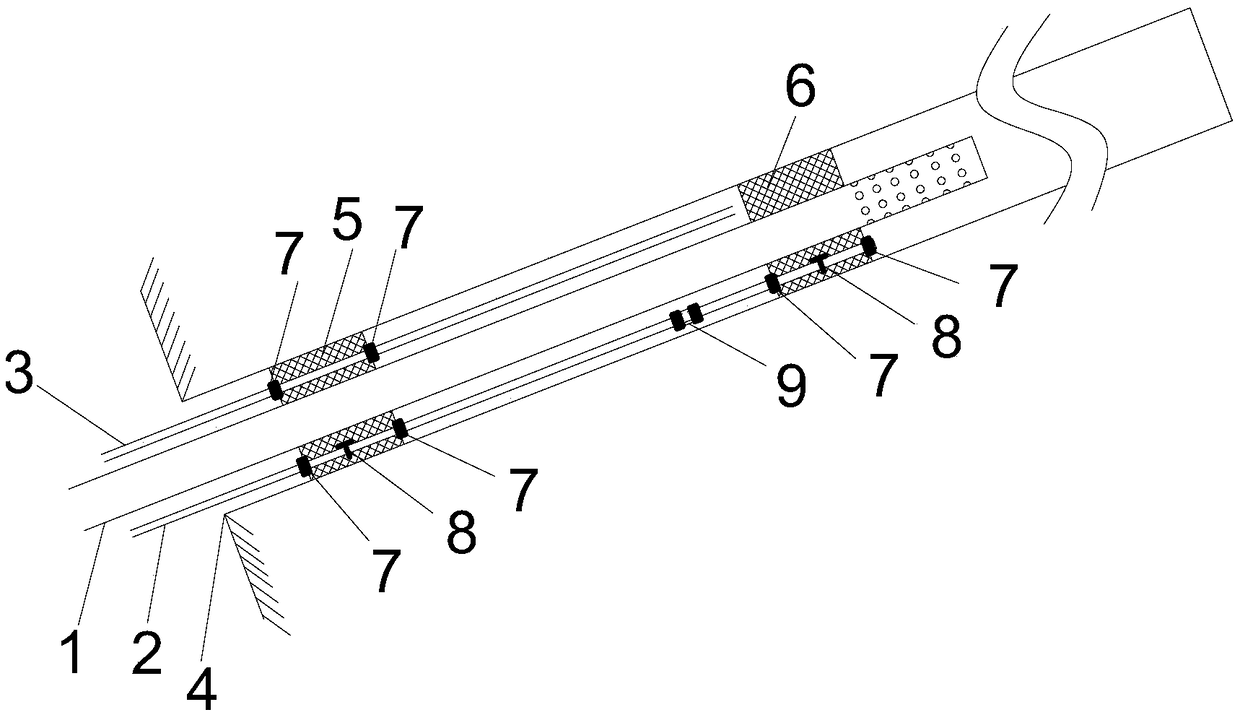

[0031] The structure of the deep coal seam gas drainage borehole is as follows: figure 1 As shown, it includes an outer plugging bag 5, an inner plugging bag 6, a drainage pipe 1 and a grouting pipe 2 arranged in the borehole 4, and the borehole 4 is an ascending borehole; The space between the outer sealing bag 5 and the inner sealing bag 6 is the grouting section; the extraction pipe 1 passes through the outer sealing bag 5 and the inner sealing bag 6; the grouting pipe 2 passes through the outer The sealing bag 5 and the inner blocking bag 6 are parallel to the axis of the extraction pipe 1;

[0032] The grouting pipe 2 is located in the pipeline inside the outer sealing bag 5 and the inner sealing bag 6, and a check valve 8 is respectively arranged in the pipeline, and a slurry outlet is respectively arranged on the pipe wall, so that the slurry is injected After the slurry pipe 2 passes through the one-way valve 8, it flows into the outer sealing bag 5 and the inner seal...

Embodiment 2

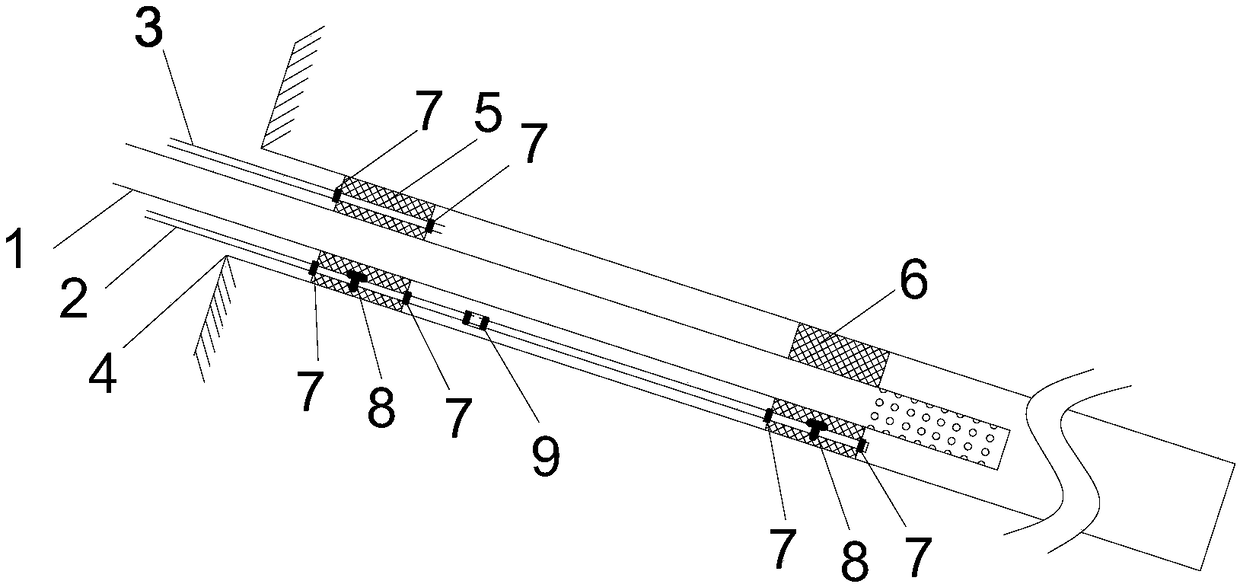

[0043] The structure of the deep coal seam gas drainage borehole is as follows: figure 2 As shown, the borehole 4 is a downward borehole; the inner mouth of the slurry discharge pipe is close to the outer sealing bag side, and the distance between the outer sealing bag is 8cm; the blasting valve is close to the outer sealing bag one side side, and the distance 25cm between the outer blocking pouch; all the other are the same as embodiment 1;

[0044] Method is with embodiment 1.

Embodiment 3

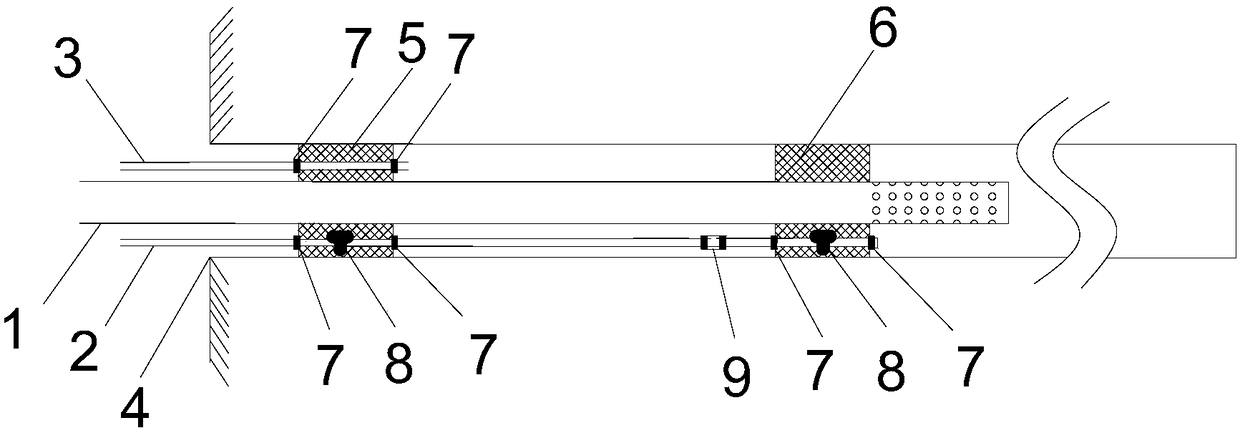

[0046] The structure of the deep coal seam gas drainage borehole is as follows: image 3 As shown, the borehole 4 is a horizontal borehole; the inner mouth of the slurry discharge pipe is close to the side of the outer sealing bag, and the distance between the outer sealing bag is 10cm; the blasting valve is close to the inner sealing bag. side, and the distance between the inner plugging bag is 15cm; the grout discharge pipe is located above the extraction pipe, and the grout injection pipe is located below the extraction pipe. All the other are with embodiment 1;

[0047] Method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com