Maintenance method of chute port of coking furnace

A chute and chute technology, applied in the field of coking, can solve the problems of inability to completely replace the brick body and complex brick shape, and achieve the effects of meeting normal production needs, prolonging service life and improving heating uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

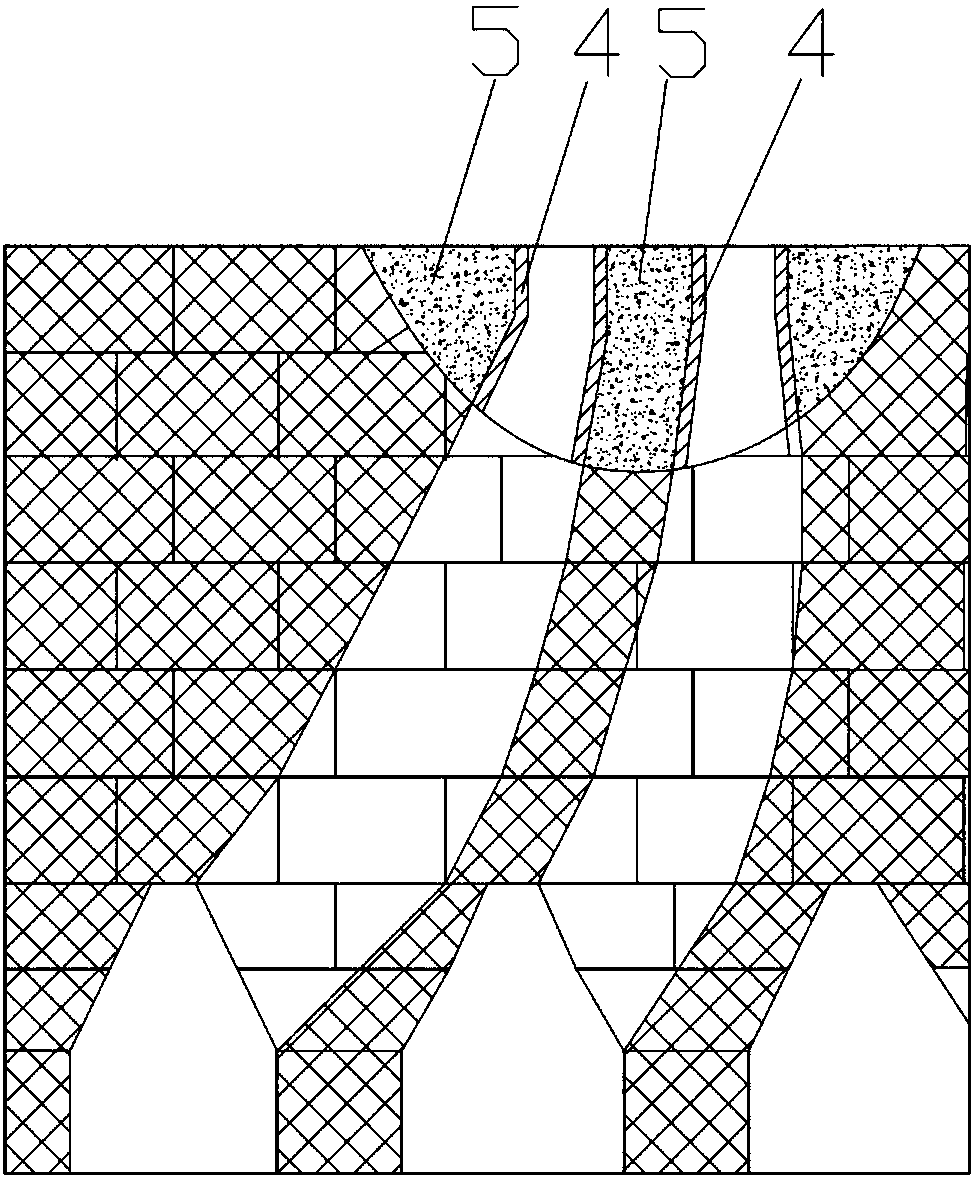

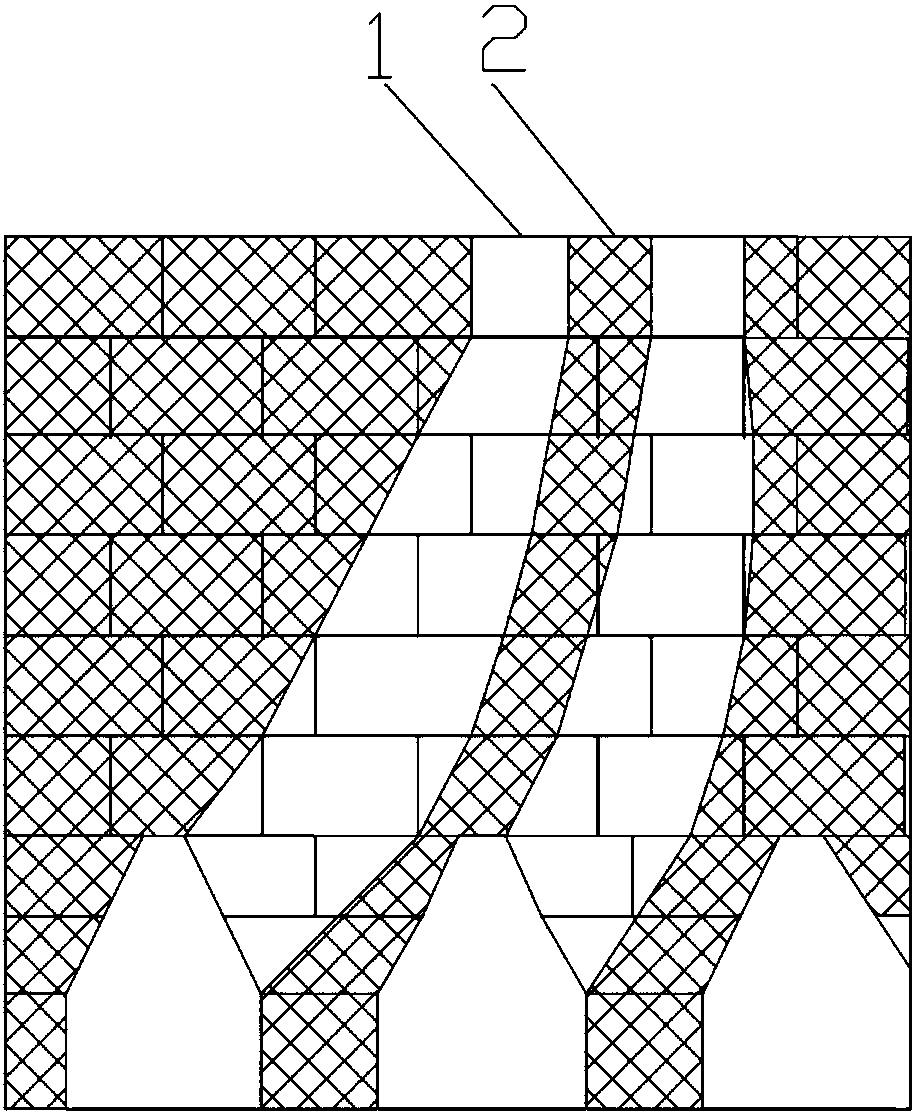

[0024] See Figure 1-6 , the present invention relates to a maintenance method for a coke oven chute, characterized in that it comprises the following steps:

[0025] 1) Remove the wall of the carbonization chamber corresponding to the chute of the coke oven to be repaired;

[0026] 2) Dredge and clean up the silica brick burnt material 3 at the chute mouth 1 to make the chute unimpeded;

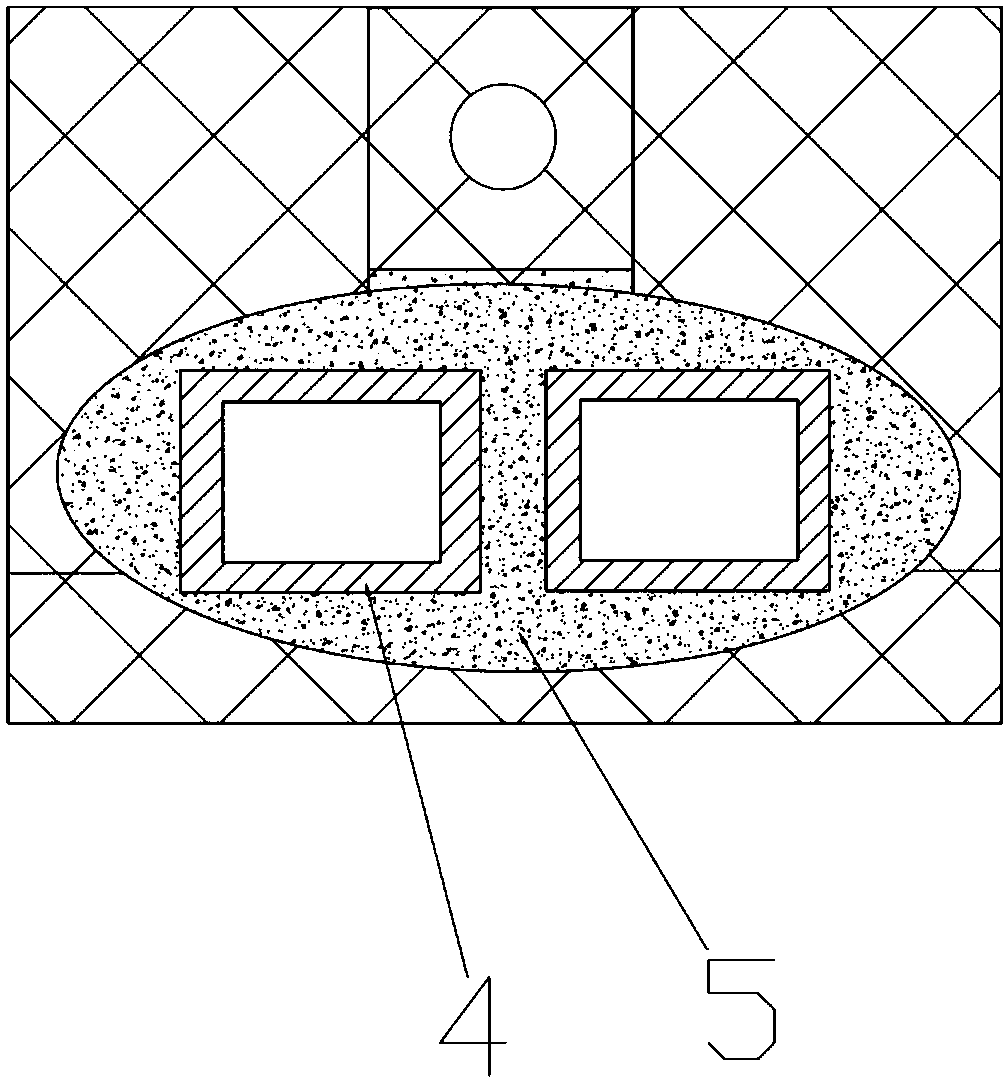

[0027] 3) Make a mold 4 consistent with the shape and size of the original chute mouth 1;

[0028] 4) Extend the mold 4 into the chute opening 1, connect the mold 4 with the chute opening to be repaired after cleaning, pour and fill the refractory material 5 along the outside of the mold 4 until it is level with the upper edge of the chute opening.

[0029] Described mold 4 is tubular, can be the special-shaped tube of square, round or other shapes, and one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com