Feeding hopper

A technology of feeding hopper and feeding port, applied in the field of hopper, can solve the problems of waste, material spillage, and the inability to open and close the feeding hopper in time, so as to achieve the effect of improving work efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

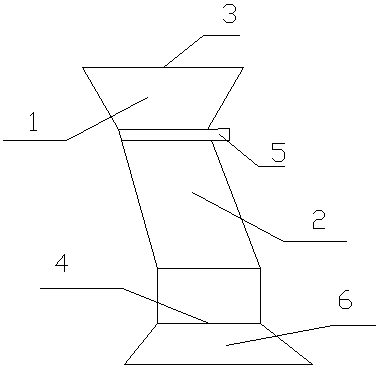

[0012] A new type of feeding hopper, including a feeding hopper 1 and a conveying pipe 2, the feeding hopper 1 is provided with a feed inlet 3, the feed inlet 3 is connected with a conveying pipe 2, and the conveying pipe 2 is provided with a discharge outlet 4 , there is an adjusting plate 5 under the feeding port 3, the adjusting plate 5 is located between the feeding port and the conveying pipe, the inner side of the feeding port 3 is provided with a connecting groove, the inner adjusting plate 5 is fixed in the connecting groove, and the adjusting plate 5 can be connected Move back and forth in the tank, the conveying pipe 2 is located between the feed port 3 and the discharge port 4, the conveying pipe 2 is located between the feed port and the discharge port in an inclined manner, the angle of inclination is 20°, and the feed port 3 is Trumpet-shaped, the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com