Stator and motor

A stator and stator core technology, applied in the shape/style/structure of the winding conductor, can solve the problems of high operation requirements, influence of the coil structure, damage to the insulation structure, etc., to achieve easy operation, simple process, reduce welding point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

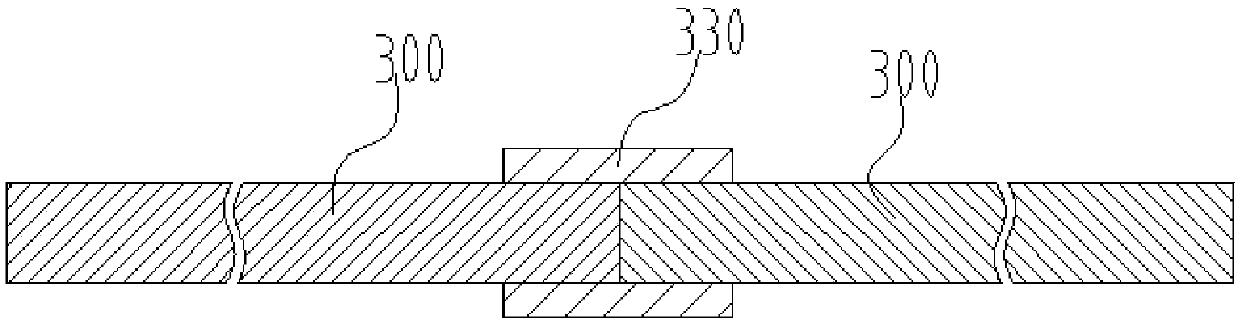

[0039] Such as figure 1 As shown, the stator provided in this embodiment includes: a plurality of coil structures 300 and a plurality of sleeves 330; one end of one coil structure 300 and one end of another coil structure 300 are respectively sleeved in the sleeves 330 and cooled Press tightly; and the two ends are in contact.

[0040]In the stator provided in this embodiment, the coil structure 300, the sleeve 330 and the coil structure 300 are sequentially connected by putting the ends of the two coil structures 300 in the sleeve 330 respectively, and then compressing them by cold pressing. . The cold-pressed connection replaces the welding method, which generates less heat and reduces the impact on the insulation structure of the outer layer of the coil structure 300; in addition, the cold-pressed connection is simple in process and easy to operate, reducing errors in the welding process, and at the same time , The cold-pressed connection method makes the coil structure 3...

Embodiment 2

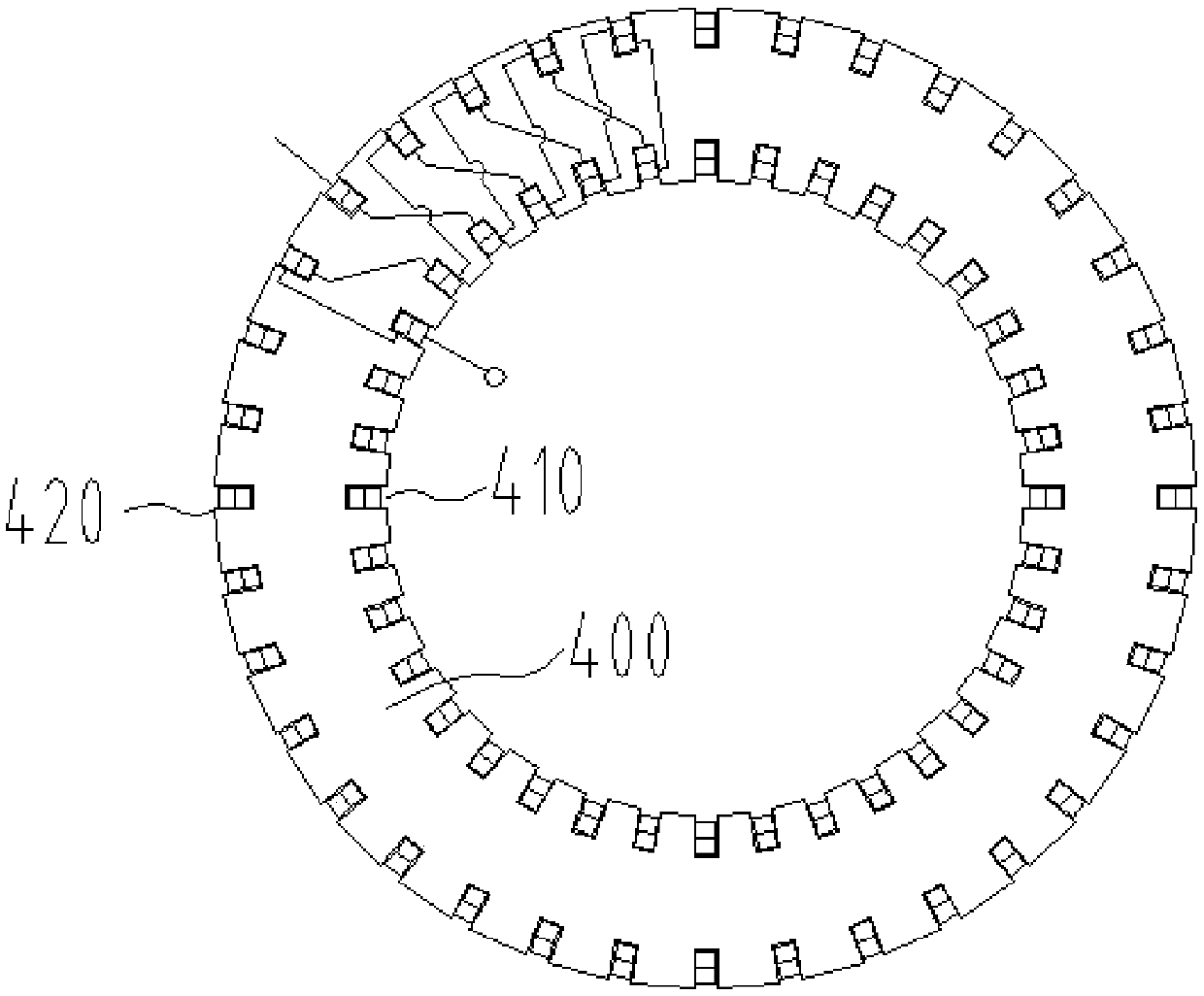

[0053] The motor provided in this embodiment includes: the stator provided in Embodiment 1.

[0054] In the motor provided by this embodiment, the welding method is replaced by cold-press connection, so that the two coil structures 300 are connected to the sleeve 330, reducing the number of welding spots, thereby reducing the influence on the resistance of the motor, so that the motor can rotate effectively. Wherein, the structure and beneficial effects of the stator have been described in detail above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com