Shock-absorbing rotary disk electrode device for avoiding bubbles in center of electrode

A technology of rotating disc electrodes and electrodes, which is applied in the direction of electrochemical variables of materials, can solve the problems of air bubbles, increase of S/N ratio, and increase of equipment maintenance costs, so as to reduce surge interference, reduce S/N ratio, and measure accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

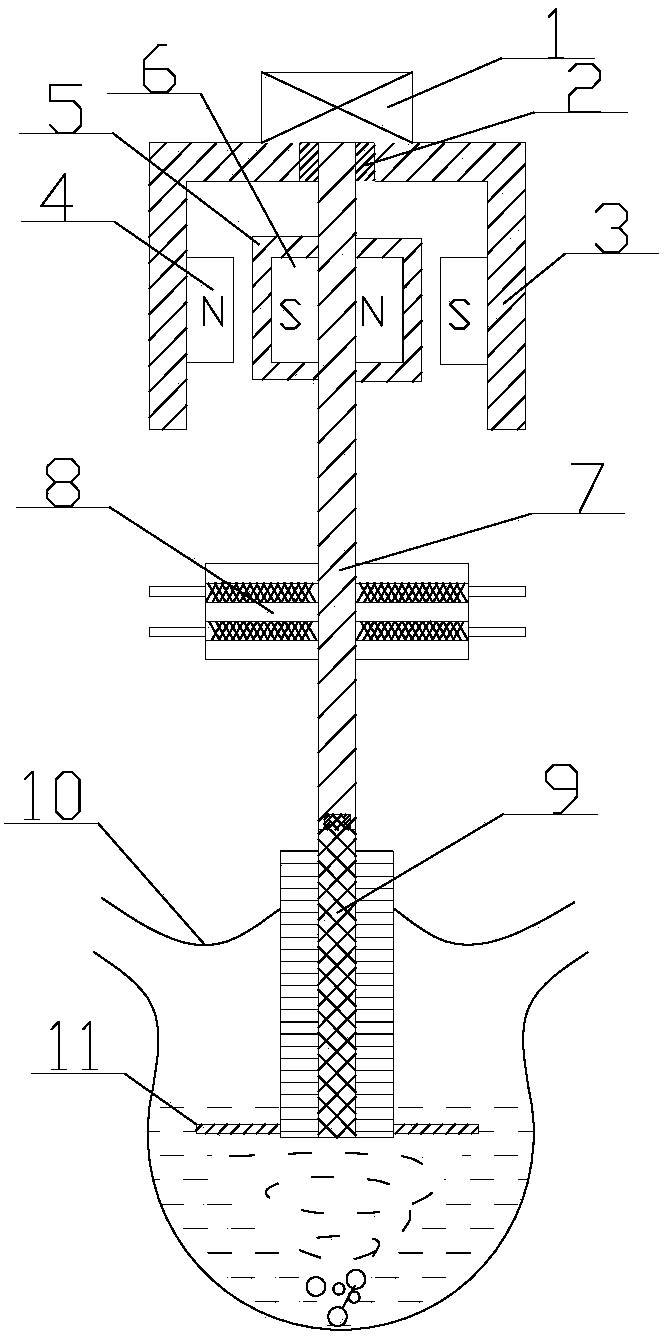

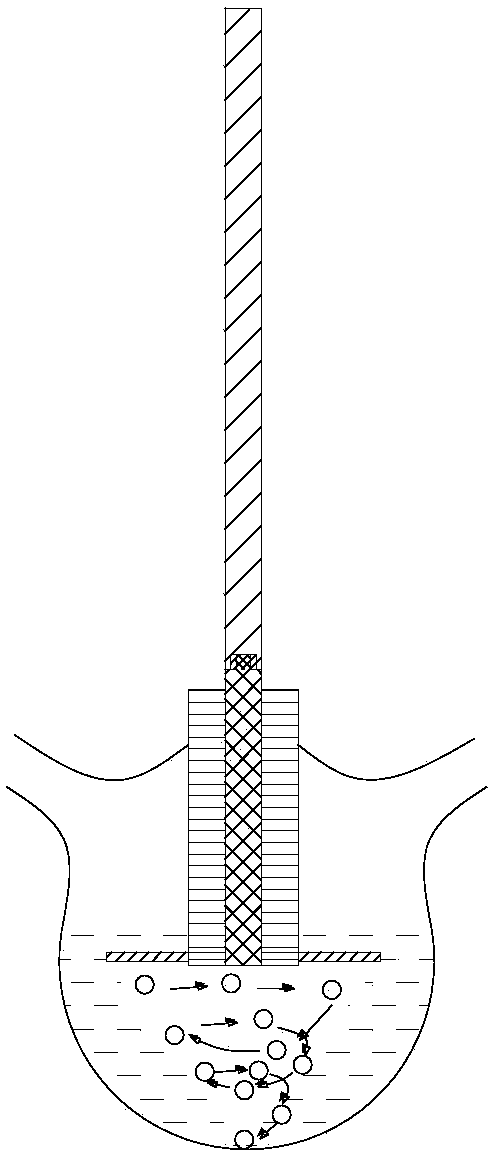

[0015] See attached for details figure 1 and 2 . Including motor, bearing, circular motor braking device, permanent magnet N-S, central shaft internal protection device, central shaft outer wall permanent magnet S-N, central shaft, signal receiving carbon brush, test electrode, three-necked flask, eddy current plate.

[0016] The motor 1 is connected with the circular motor brake device 3, the bearing 2 is connected externally with the circular motor brake device 3, and the inside is connected with the central shaft 7, and the permanent magnet N-S 4 is connected with the inner wall of the circular motor brake device 3, The N pole is opposite to the S pole, the outer wall permanent magnet S-N of the central axis 7 is connected with the central axis 7, the inner protection device of the central axis 7 is connected with the outer wall permanent magnet S-N of the central axis 7, and is fixed on the central axis 7, and the central axis 7 is connected with the central axis 7. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com