Preparation method of columnar jointing basalt undisturbed rock core

A columnar joint and basalt technology, applied in the field of geotechnical engineering, can solve problems such as disturbance, poor core success rate, and inability to reflect the real mechanical properties of rock samples, so as to reduce impact disturbance and avoid disturbance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Refer to attached picture. The method for preparing the original core of columnar jointed basalt of the present invention comprises the following steps:

[0029] (1) Excavation of sampling holes

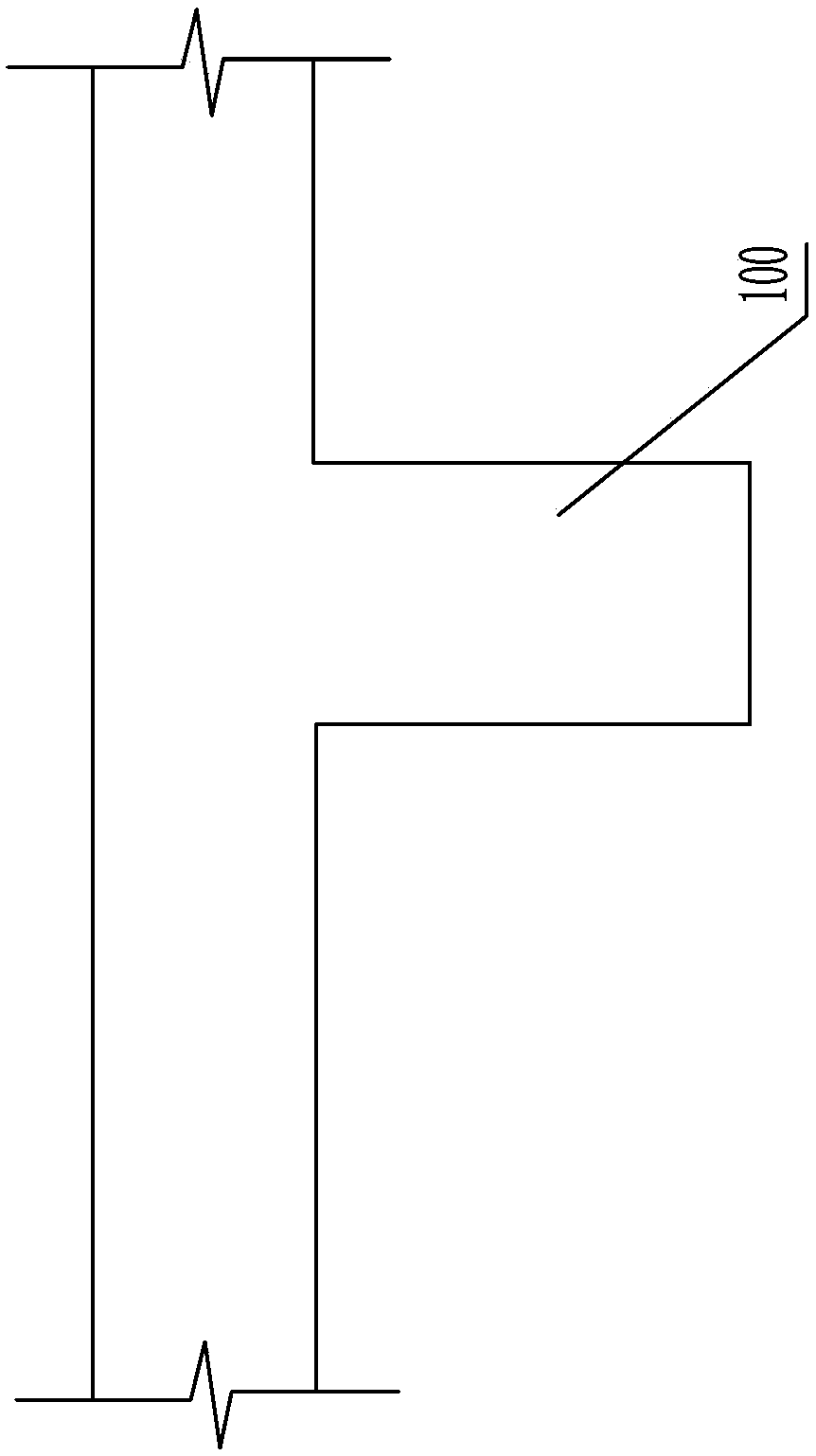

[0030] Select the area where columnar joints and groundwater develop at the same time, excavate 100 sampling holes, the diameter of the hole is not more than 3m, and the depth is 5-10m, which can meet the work of construction personnel and the placement of sampling equipment, see figure 1 .

[0031] (2) Freeze construction

[0032] As long as the natural water content of the formation is greater than 10%, and the groundwater flow or infiltration velocity is less than 10m / d, freezing construction can be used in the area of the sampling hole.

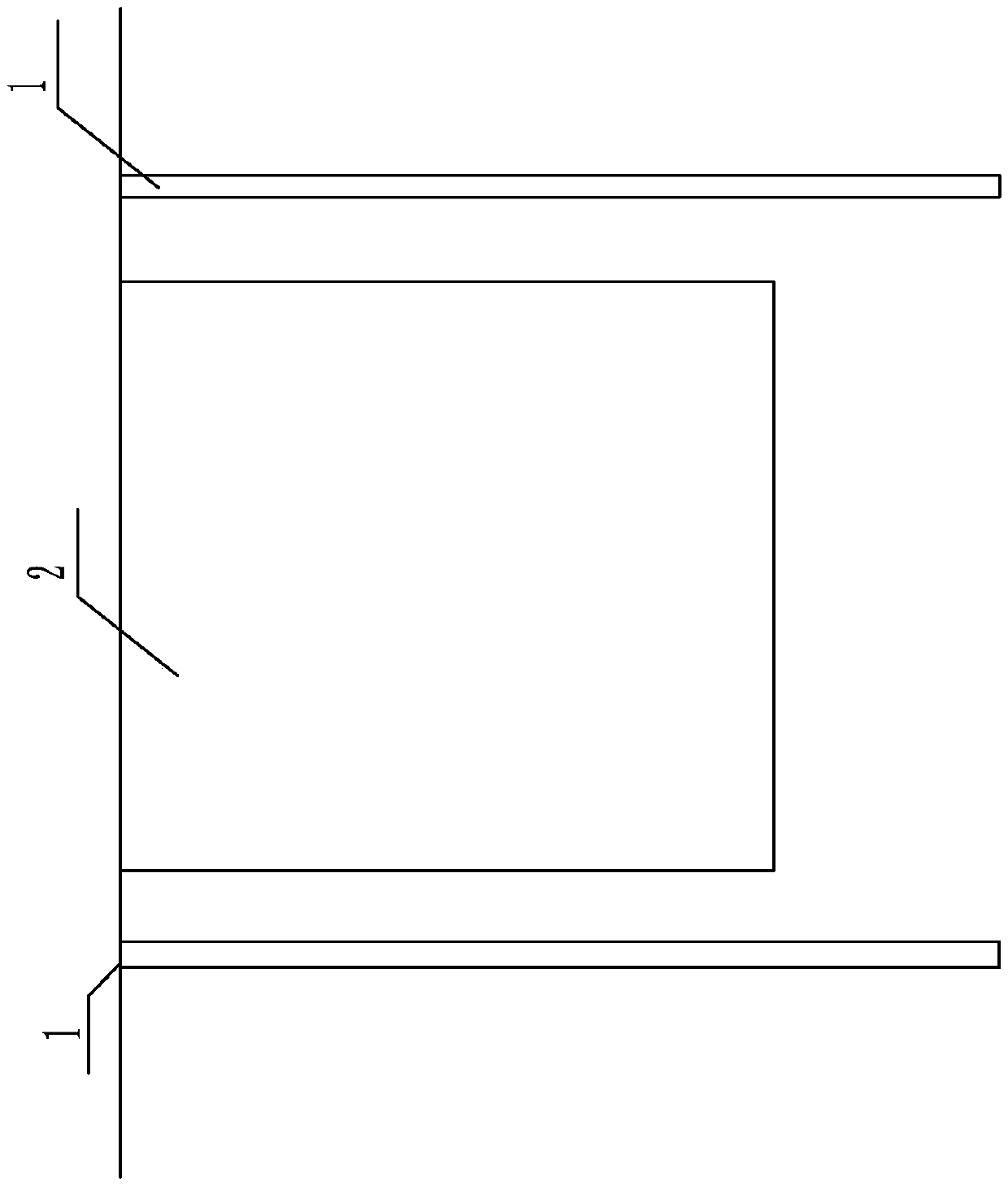

[0033] In order to facilitate the construction and ensure the freezing effect, the sampling area is generally set on the bottom plate of the sampling hole. The sampling area 2 contains columnar jointed basalt rock mass with relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com