Low-NOx stable combustion burner for boiler

A technology for burners and boilers, which is applied in the direction of burners, burners burning powder fuel, and combustion methods, etc., which can solve the problems of increasing resistance, prolonging the flame stroke, and disadvantages, so as to reduce the generation of NOx and reduce coking and slagging Problems, the effect of preventing flame from sticking to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

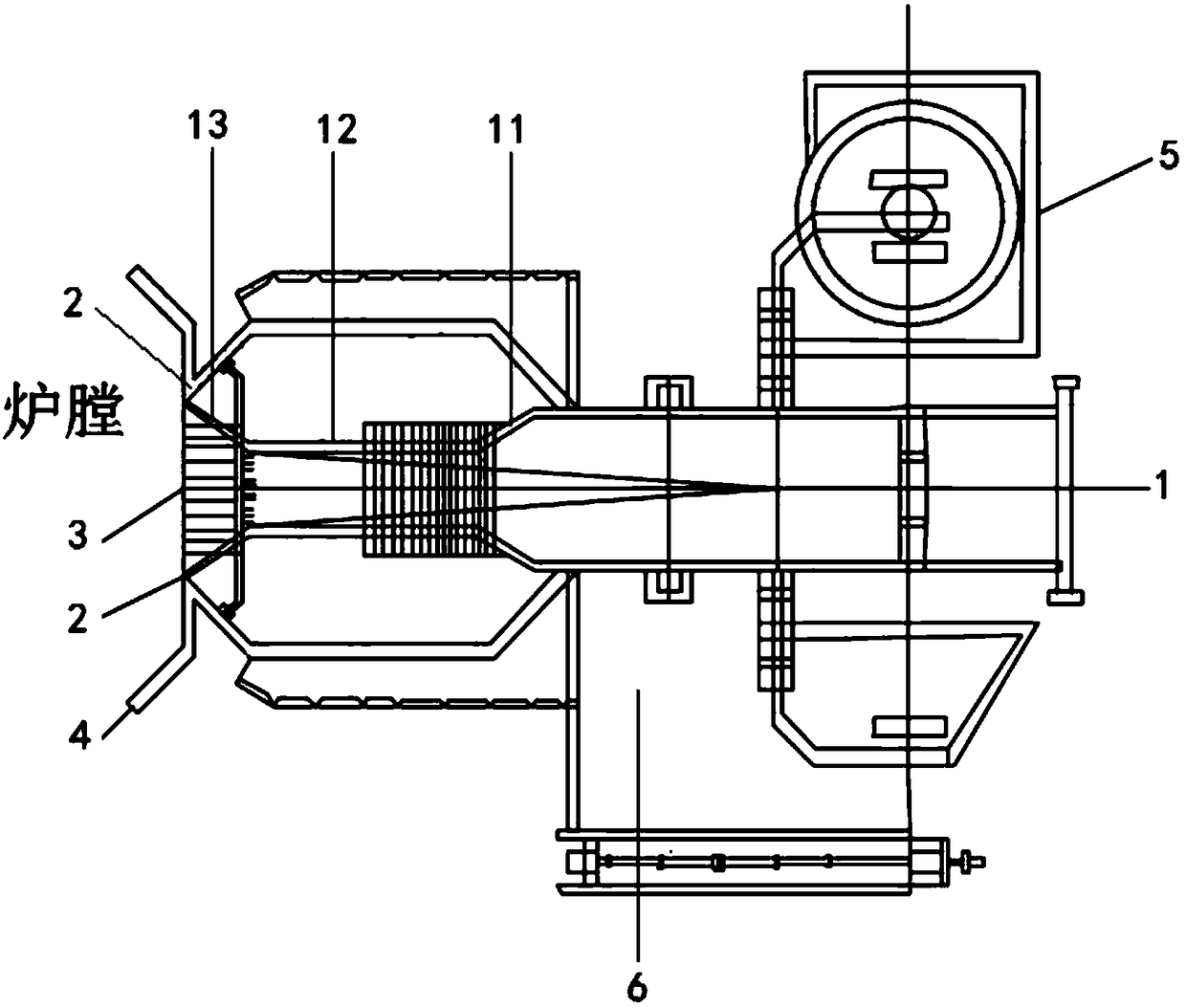

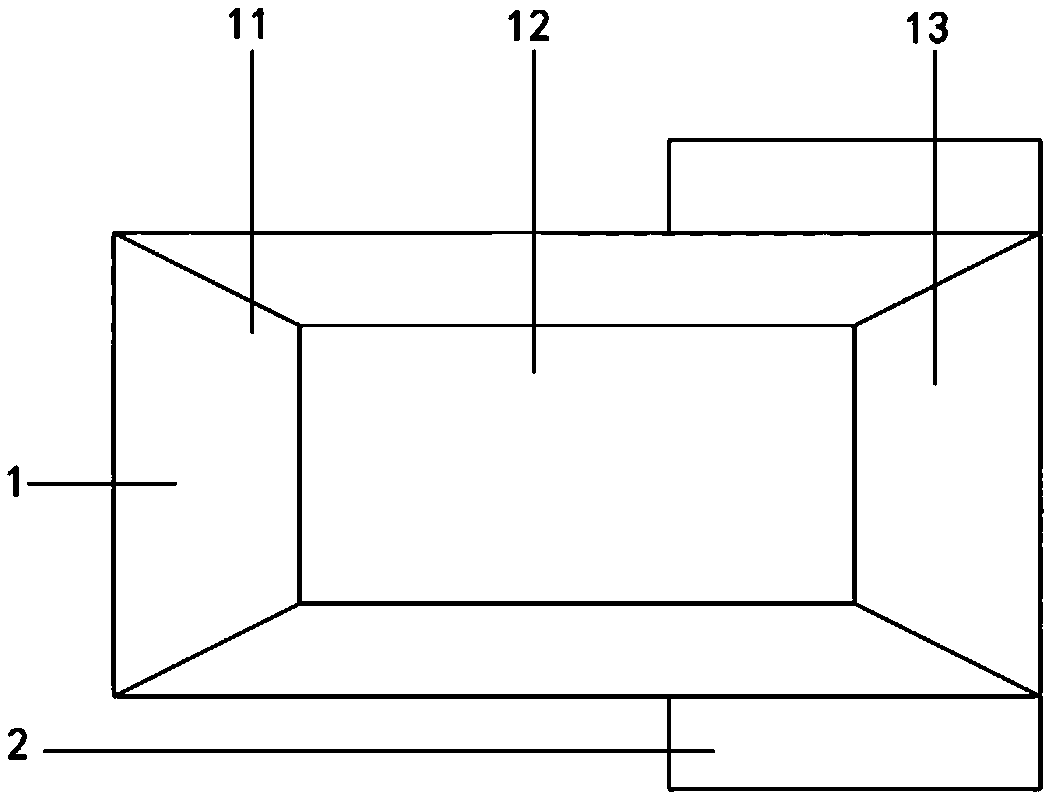

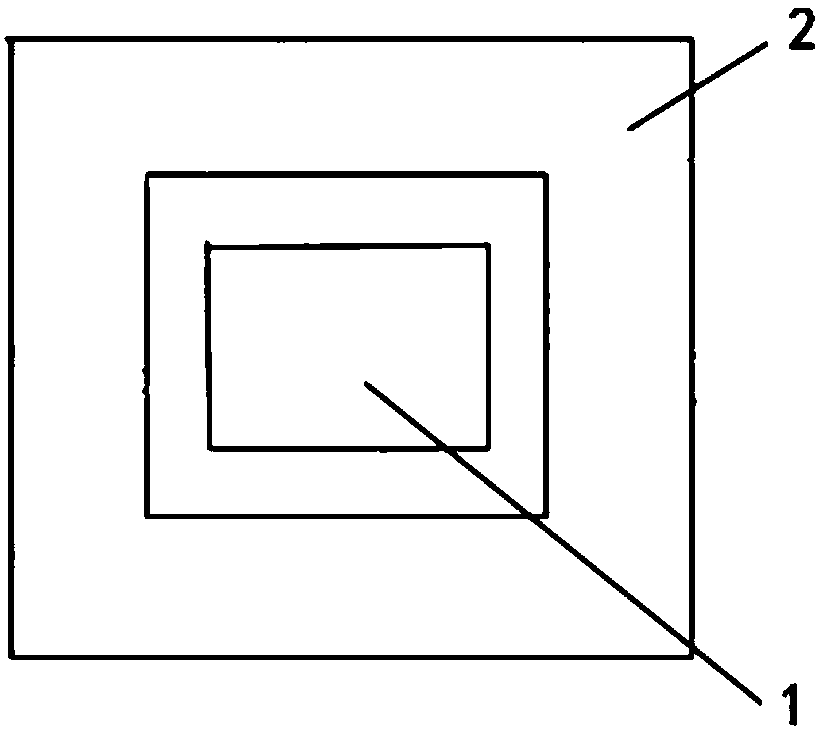

[0027] A low NOx stable combustion burner used in a boiler, comprising a primary air duct 1 and a peripheral air duct 2 communicating with the furnace, such as figure 1 As shown, the primary air duct 1 is provided with a reducer 11 , a straight duct 12 and an expander 13 in sequence before it passes into the furnace, and the perimeter air duct 2 is sleeved outside the primary air duct 1 . The maximum cross-sectional area of the reducer 11 and the expander 13 is the same, as figure 2 , 3 As shown, the ratio of the maximum cross-sectional area to the minimum cross-sectional area is about 1.2-3:1, the cross-section of the primary air duct 1 is rectangular or circular, the cross-section of the perimeter air duct is "back" or circular, and the cross-sectional area of the perimeter air duct The ratio to the cross-sectional area of the outlet of the primary air duct is 1:2-3. The ratio of the wind speed between the perimeter air duct and the primary air duct is 1.5-3:1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com