Control system and method for hydrogen-rich blast furnace based on low-quality oxygen and large humidification

A control method and control system technology, applied in the field of iron and steel production, can solve problems such as the fragile balance of blast furnace energy utilization, increase the difficulty of production scheduling, and increase the number of blast furnaces, so as to reduce the number of blast furnaces produced, reduce smelting costs, and improve furnace charges Restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

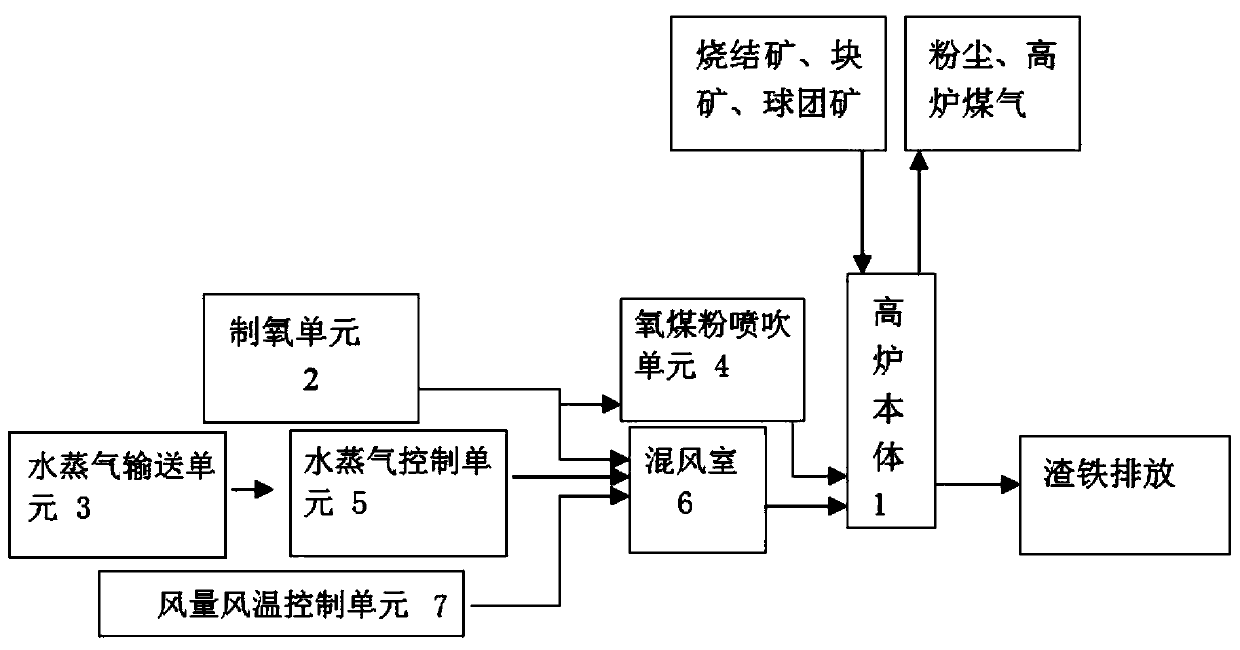

[0052] As shown in 1, the present invention discloses a hydrogen-rich blast furnace control system based on low-quality oxygen and large humidification, which includes a blast furnace body 1, and the top of the blast furnace body 1 is provided with a charging charging unit and a gas processing unit. The bottom end of the blast furnace body 1 is provided with a slag processing unit, and the charge adding unit, the gas processing unit and the slag processing unit etc. are all kept as they were in the invention without any modification; An oxygen generator unit 2 and a water vapor delivery unit 3 are provided, wherein the oxygen generator unit 2 uses an oxygen generator to prepare oxygen with a purity ≥ 90%, and the model of the oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com