Gravity transmission system

A transmission system and gravity technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of complex structure, high manufacturing cost and long design cycle of motor drive system and chain drive system, and achieve simple structure, Low manufacturing cost and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

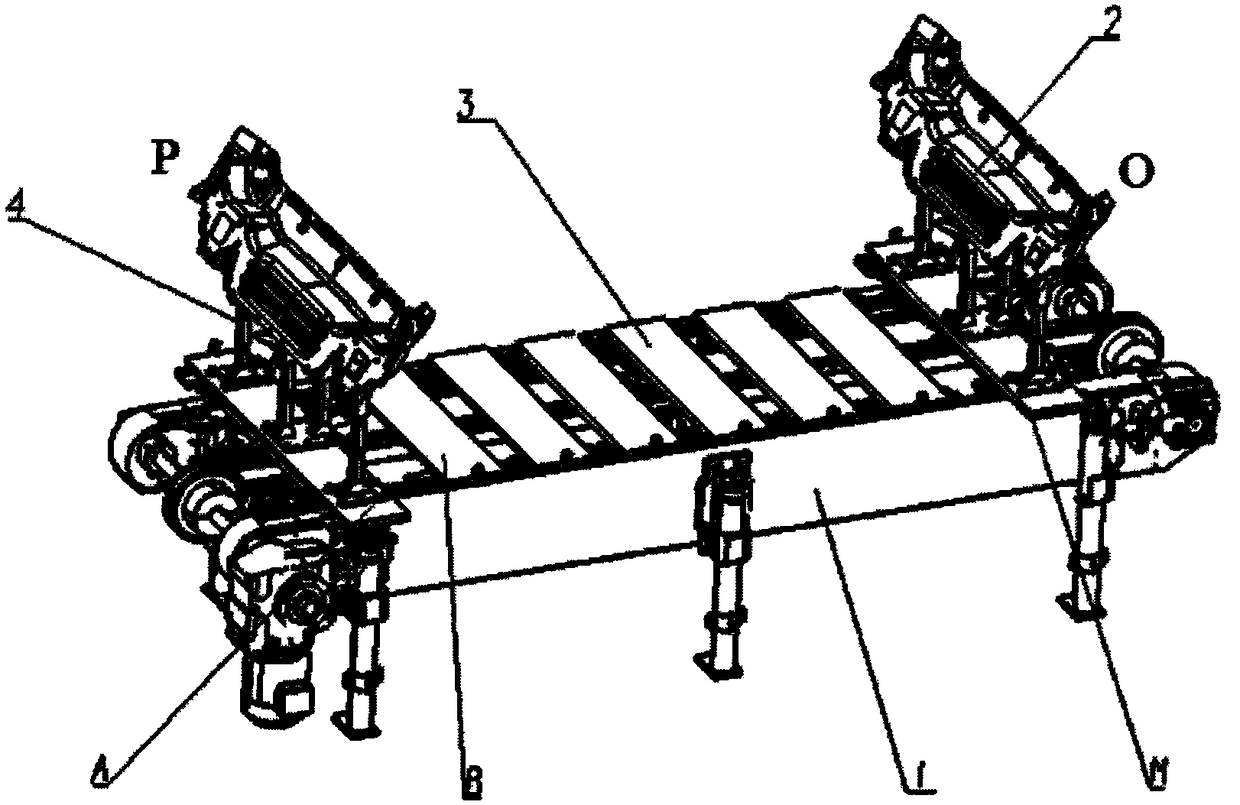

[0027] figure 2 It is a schematic diagram of the gravity transmission system provided in this embodiment, and the gravity transmission system is composed of a frame 5, a tray mechanism 6, a deceleration mechanism 7, a blocking mechanism 8, a pneumatic turning mechanism 9, and the like.

[0028] Frame 5 both sides are provided with guide rail 14, and guide rail 14 adopts hexagonal steel guide rail. The guide rail 14 comprises a forward transport guide rail 14-1 located above the frame 5 and a return guide rail 14-2 located below the frame 5, the forward transport guide rail 14-1 is inclined downward along the transport direction Z, and the return guide rail 14-2 is inclined downward along the return direction R slopes down. The two ends of the frame 5 are point O (upstream along the transport direction Z) and point P (downstream along the transport direction Z) of the loading po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com