Traveling wheel mechanism with automatic lifting function and for rail trolley

A technology of automatic lifting and traveling wheels, applied in railway car body parts, bogies, transportation and packaging, etc., can solve the problems of testing equipment, testing equipment and personnel safety hazards, rubber tire oil corrosion, and high center of gravity of equipment. , to achieve the effect of compact structure, no damage to the track, and not easy to derail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0030] This embodiment provides a traveling wheel mechanism with automatic lifting function for rail trolleys. The mechanism has convenient operation, compact structure, simple processing technology, heavy bearing capacity, no derailment, flexible travel, no damage to the track, stable lifting, etc. Features, can realize safe and reliable travel, lifting and tightening limit between rail trolley and I-shaped track.

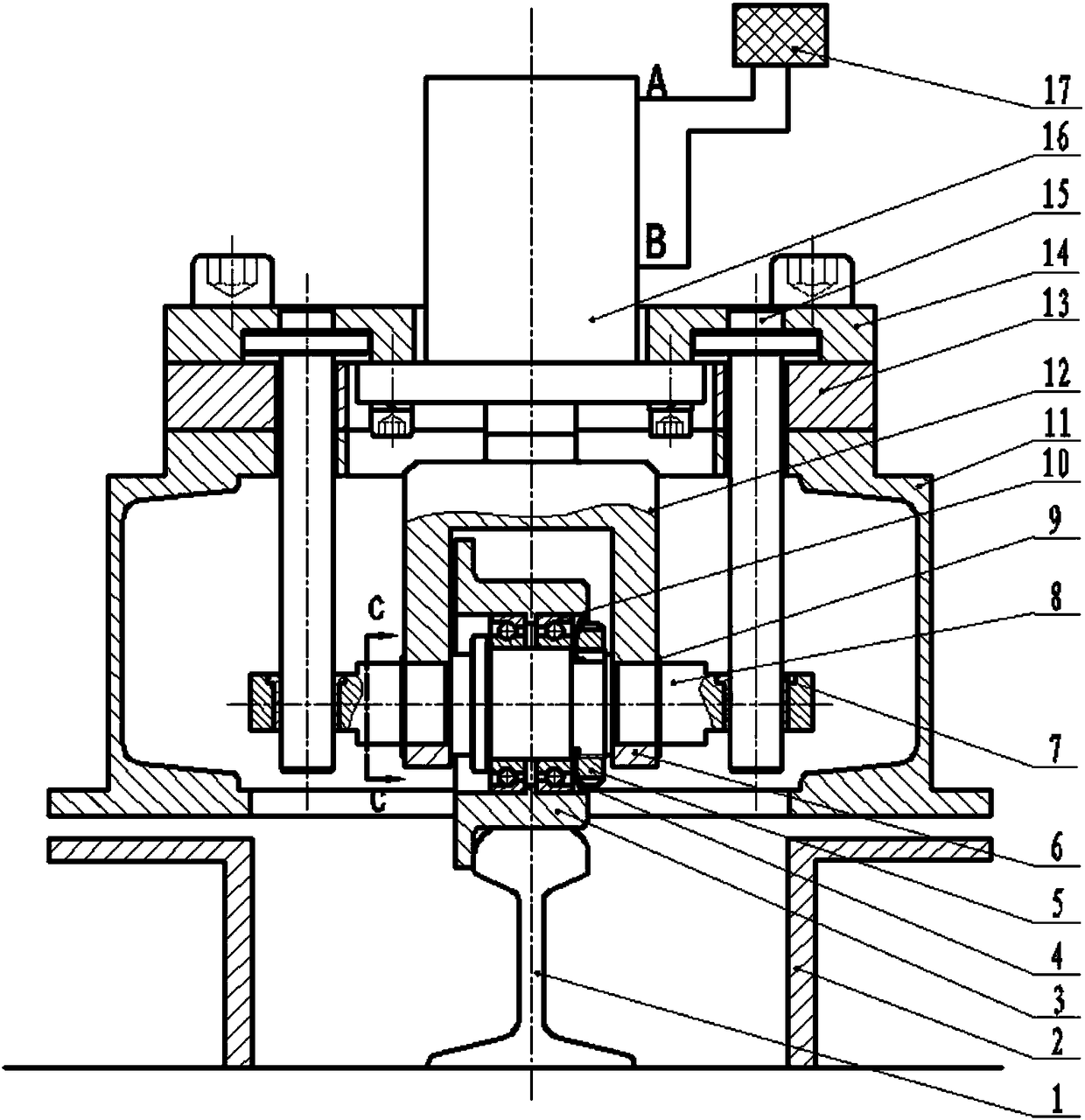

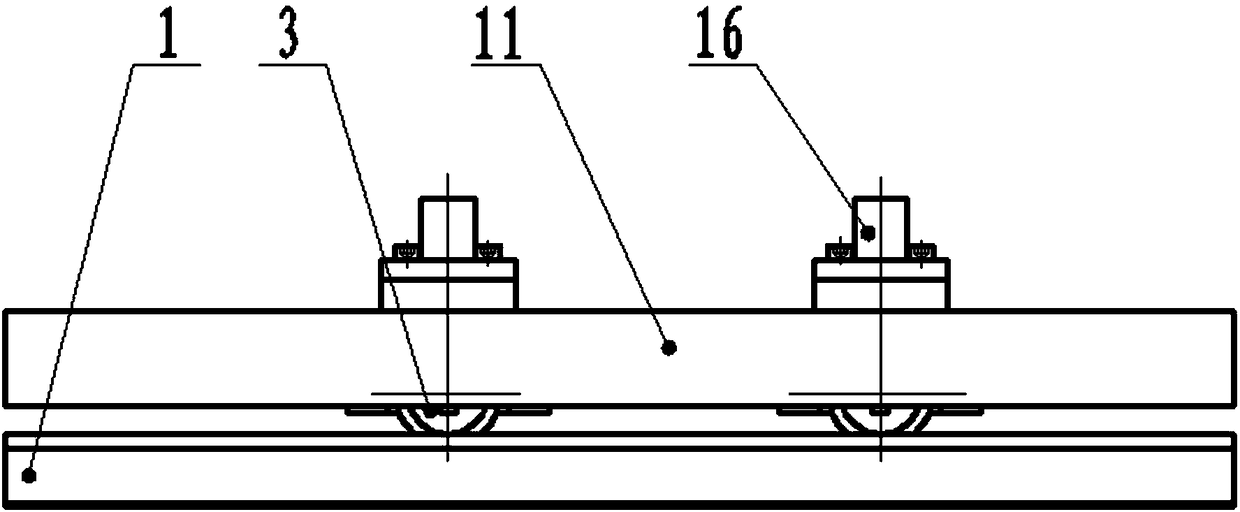

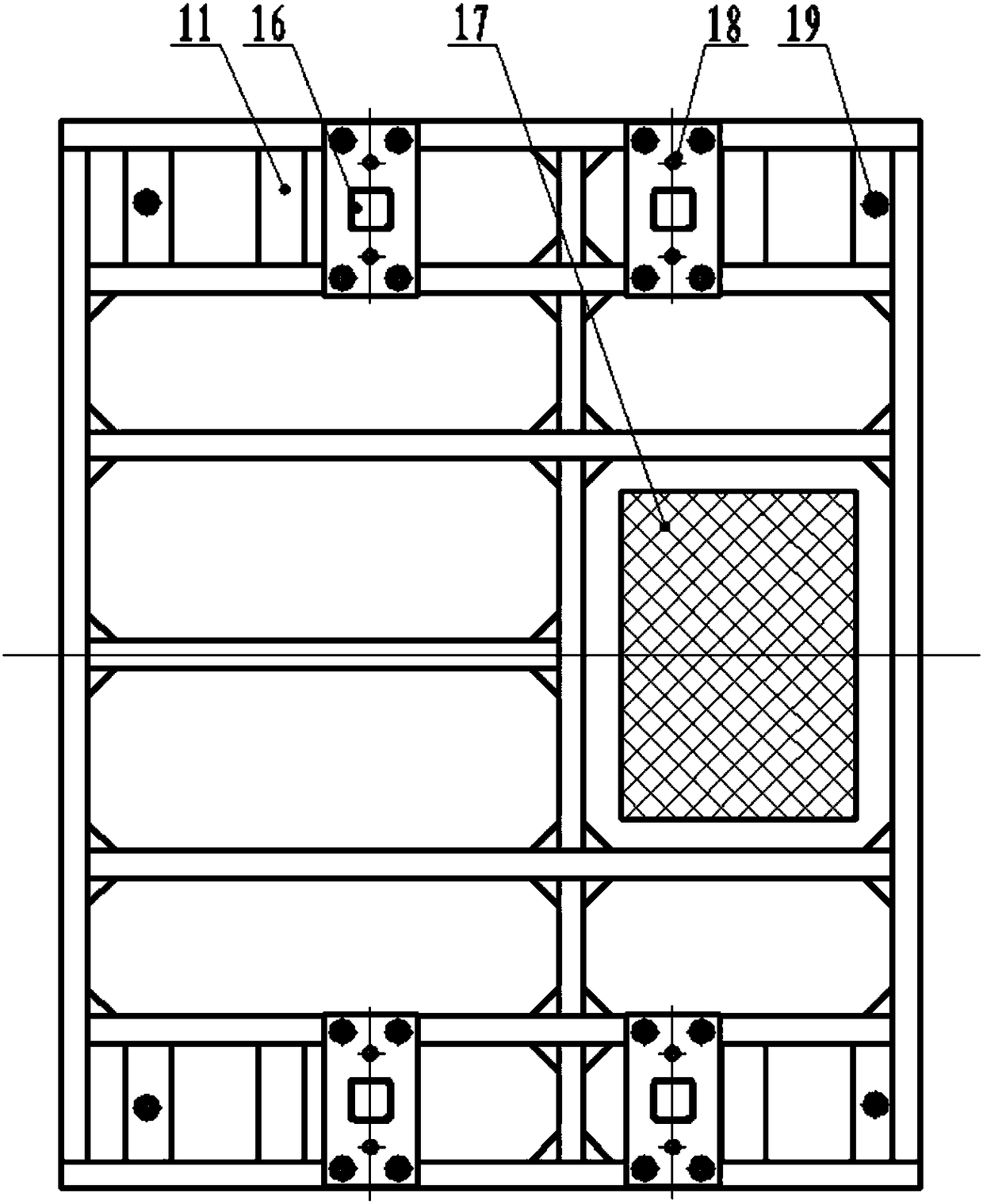

[0031] Such as figure 1 with figure 2 As shown, the traveling wheel mechanism with automatic lifting function includes: a traveling structure, a hydraulic lifting structure and a fastening and limiting structure; the I-shaped track 1 is matched with it.

[0032] The traveling structure includes: traveling wheel 3, axle 8 and traveling wheel mounting bracket 12. The selected material of the axle 8 is 40Cr quenched and tempered material, which has good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com