Air pumping device and preparation method of laminated glass

A technology of air extraction device and laminated glass, which is applied in lamination devices, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of not being able to meet mass production, inconvenient operation, and low energy consumption, and achieve Reduce the possibility of air bubbles, simplify the structure, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

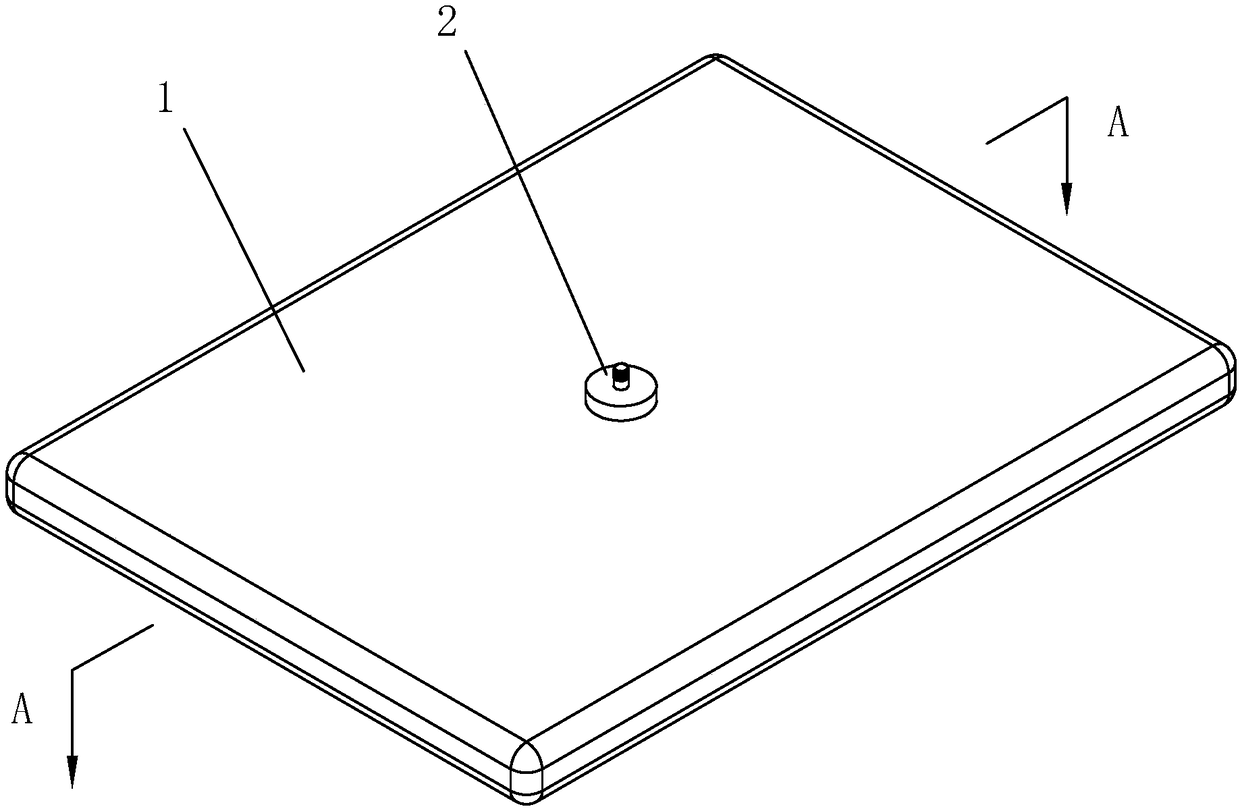

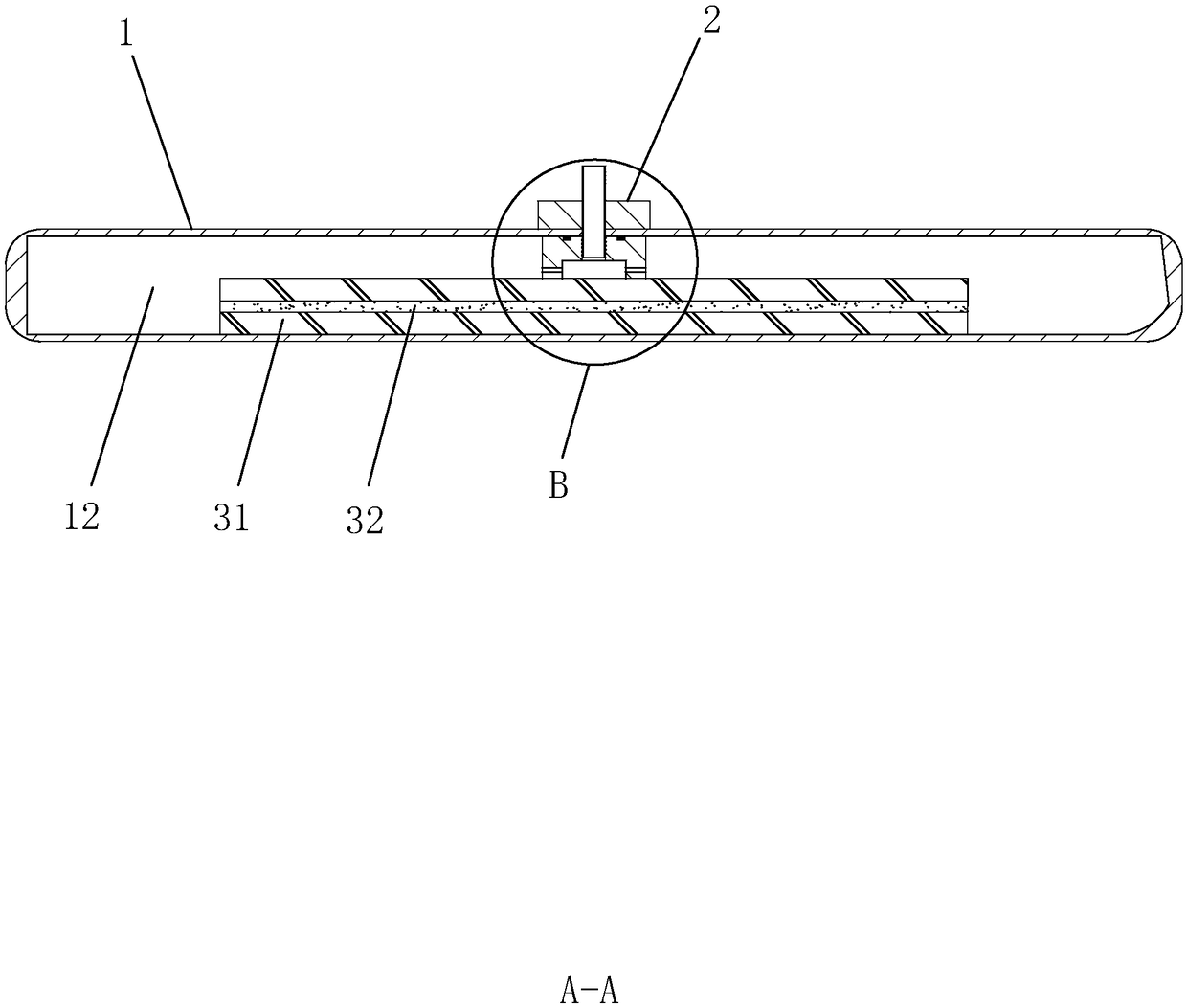

[0040] Embodiment one: a kind of air extraction device, such as figure 1 As shown, it includes a plastic bag 1 and an air pumping assembly 2 installed thereon. The air pumping assembly 2 is connected to an external vacuum pump to vacuum the inside of the plastic bag 1 .

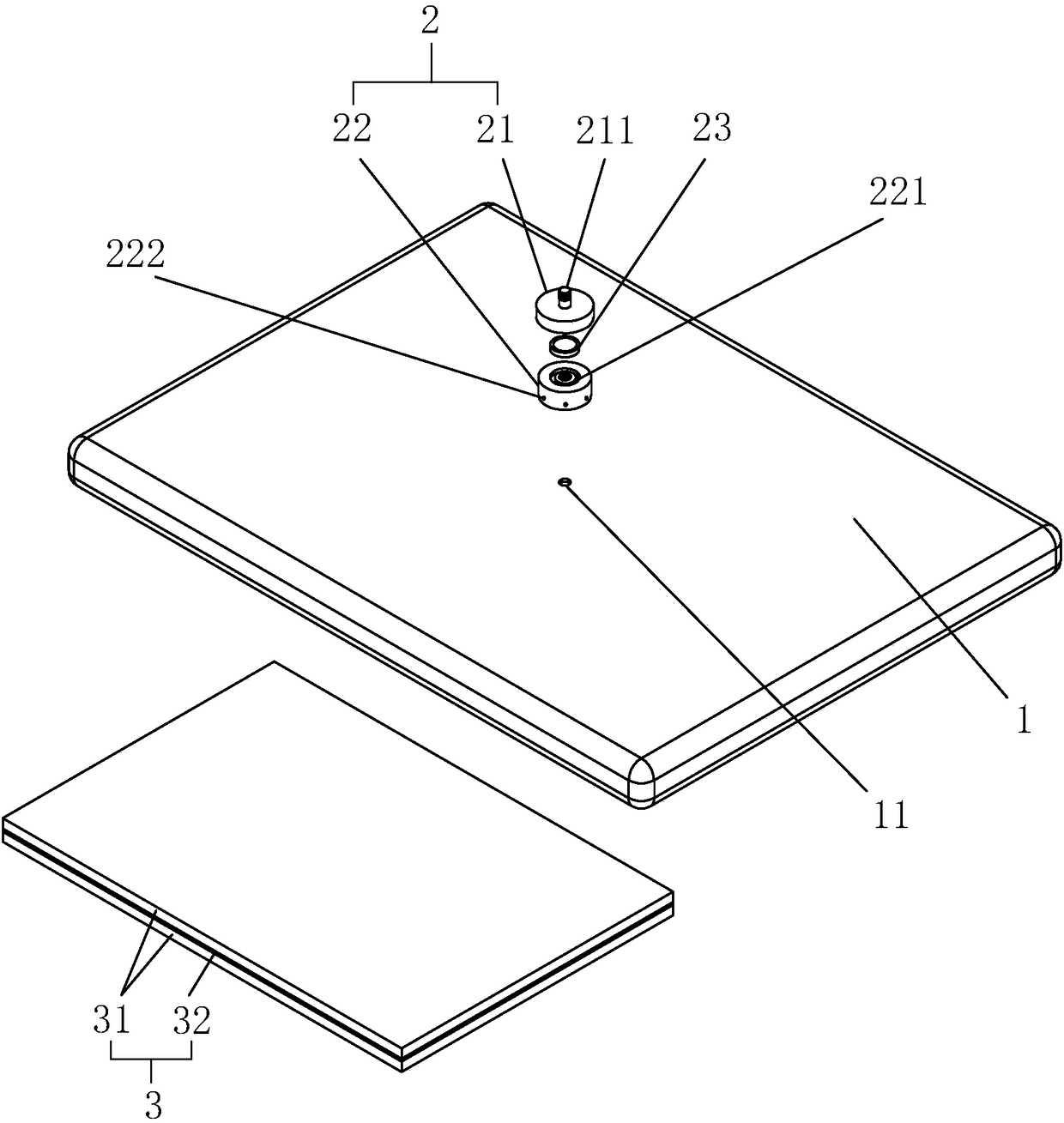

[0041] refer to figure 2 , The plastic bag 1 is provided with a through hole 11, and the air extraction assembly 2 is installed at the through hole 11. The plastic bag 1 can adopt high-temperature-resistant plastic film to form through heat-pressing edge sealing.

[0042] refer to figure 2 , The air extraction assembly 2 includes an outer connector 21 and an inner connector 22, and the outer connector 21 and the inner connector 22 can be made of aluminum alloy. An air guide tube 211 is fixed on the outer connector 21 along its axis, and the two ends of the air guide tube 211 protrude from the main body of the outer connector 21 . The outer diameter of the air duct 211 is equal to or slightly smaller tha...

Embodiment 2

[0052] Embodiment two: a kind of preparation method of laminated glass, comprises the following steps:

[0053] S1: Lay the plastic film flat on the workbench and fold it in half, then place two glass plates 31 of the same size and a piece of film 32 between the plastic films, the edge of the plastic film is about 5-10 cm longer than the glass plate 31;

[0054] S2: Open a hole 11 in the middle of one side of the plastic film, install the air extraction component 2 at the through hole 11, and then use a hot-press edge sealing machine to seal the open sides of the plastic film on three sides to form a plastic bag 1, and the air extraction component 2 passes through Connect the trachea to the external vacuum pump for 10-30min;

[0055] S3: Transfer the plastic bag 1 together with the glass plate 31 and the film 32 inside the reaction kettle, the temperature in the reaction kettle is raised to 130°C, the temperature deviation does not exceed ±5°C, and the pressure is increased to...

Embodiment 3

[0057] Embodiment 3: A preparation method of angled glass, changing step S1 in Embodiment 2 to use three glass plates 31 and two films 32 alternately stacked between plastic films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com