Automatic tapping machine for hoop nut

A technology of automatic tapping machine and clamp nut, which is applied in thread cutting machines, metal processing equipment, thread cutting devices, etc., can solve the problems of potential safety hazards, large floor space, low processing efficiency, etc., and achieve low labor costs, The effect of reducing the floor space and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

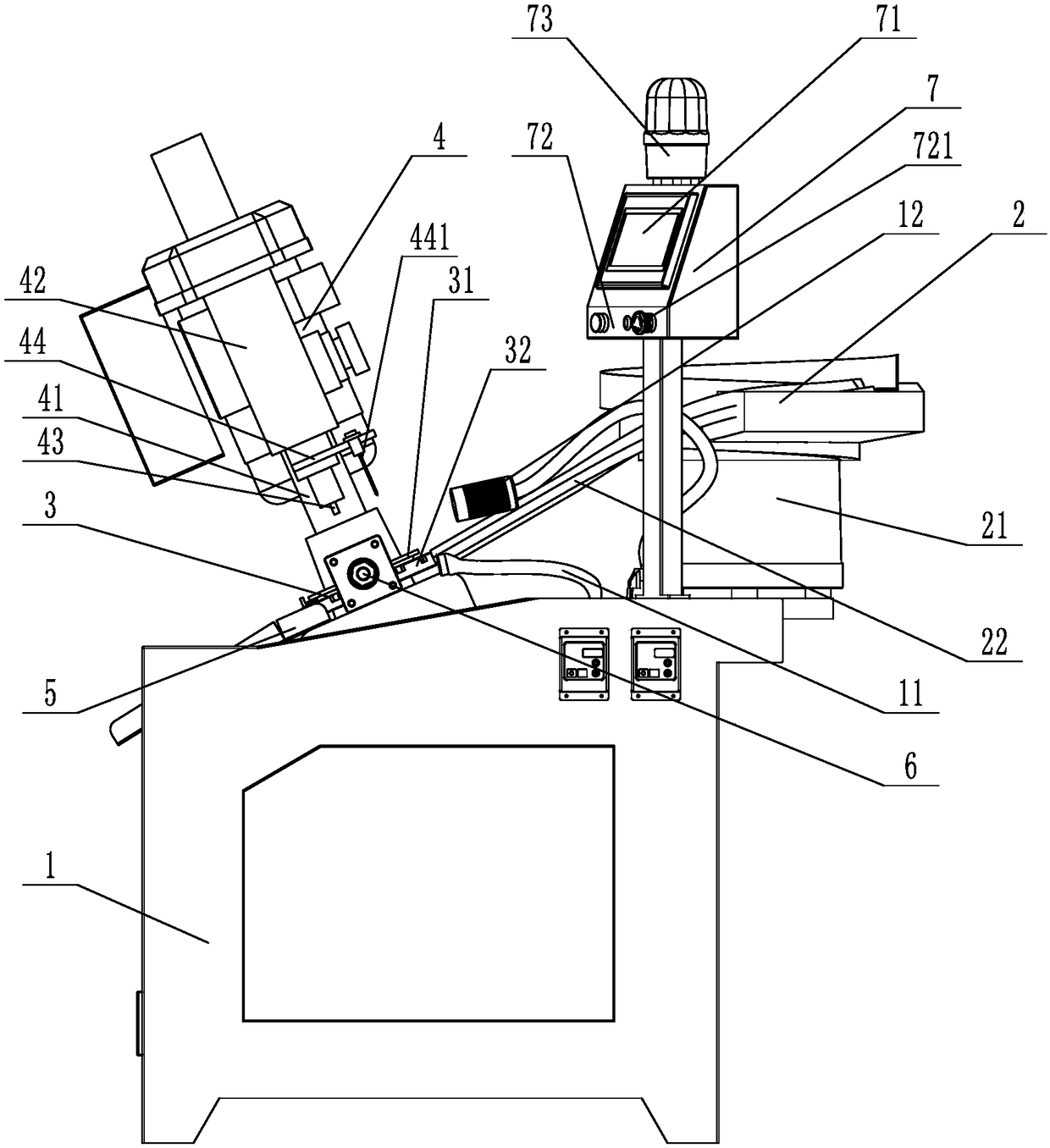

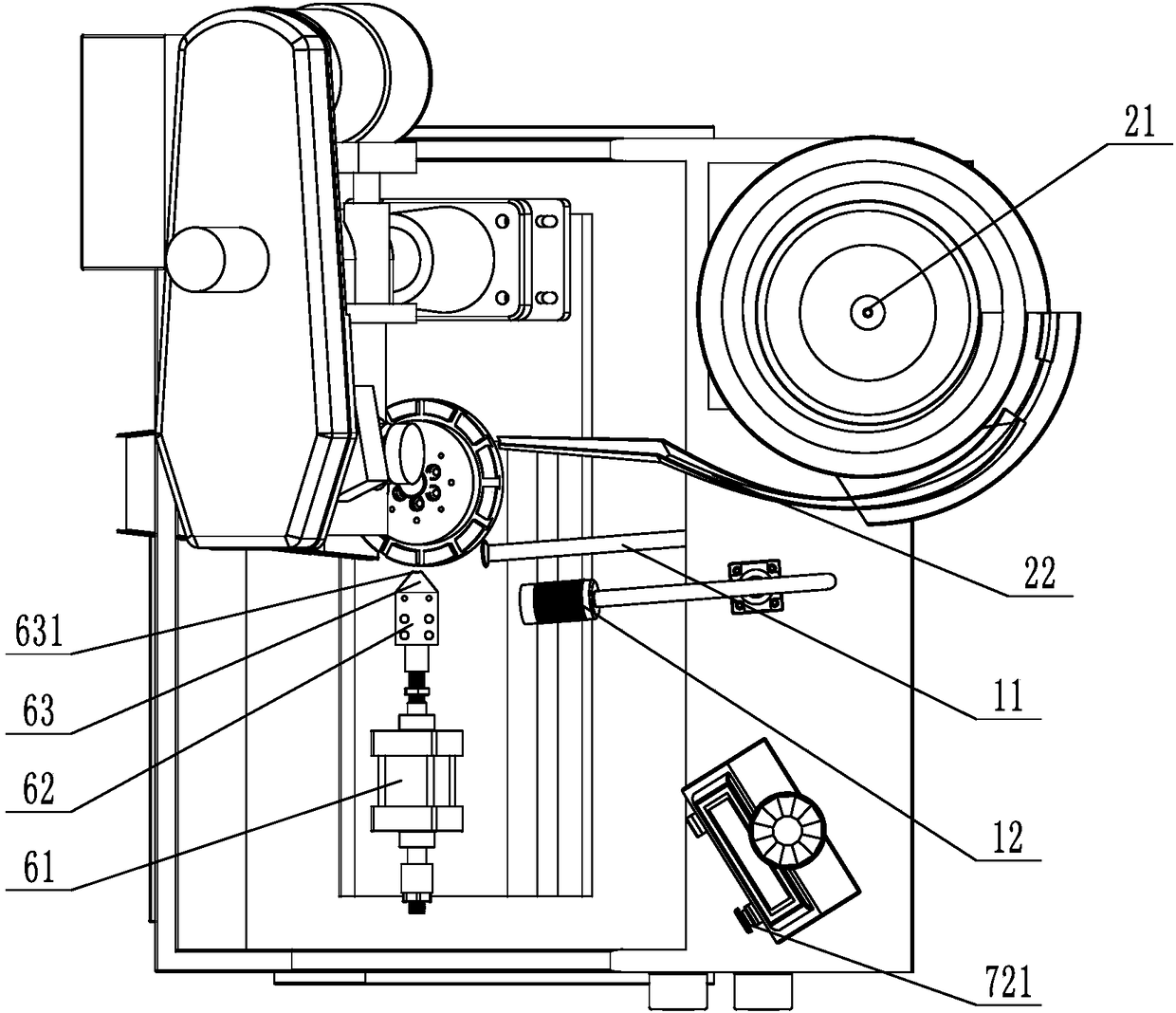

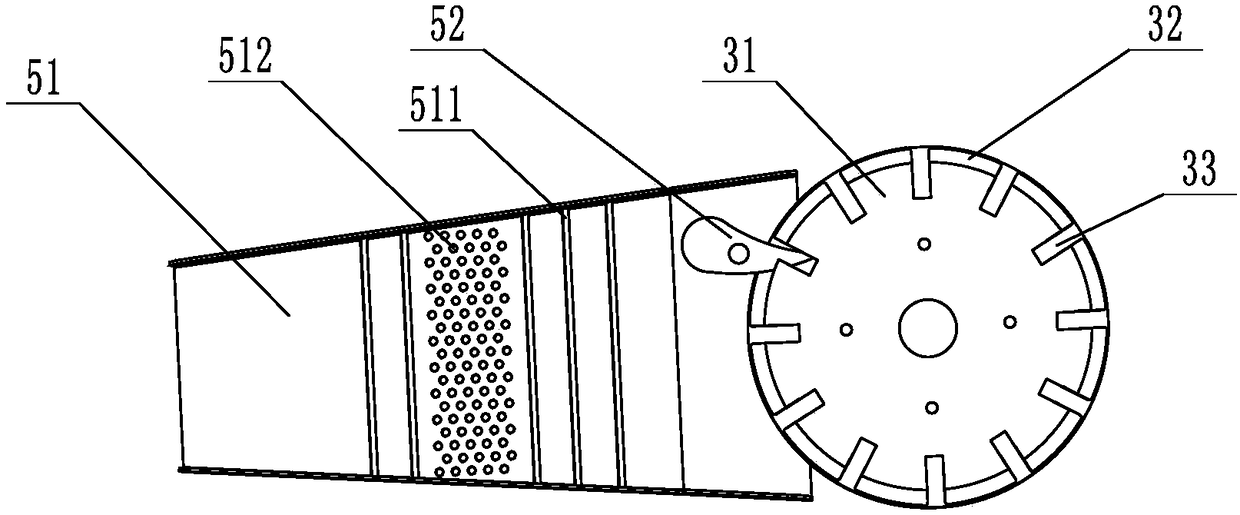

[0020] Such as Figure 1 to Figure 3 A kind of automatic threading machine that is used for clamp nut shown, comprises frame 1, feeding device 2, clamping device 3, tapping device 4 and discharging device 5, and described feeding device 2 includes the The vibrating plate 21 on the frame 1 and the feeding track 22 connected with the vibrating plate 21, the clamping device 3 includes a first fixed plate 31 and a second fixed plate 32 arranged up and down, and the first fixed plate 31 and the second fixed plate The outer edge of the fixed disk 32 is evenly distributed with several openings 33 that are compatible with the clamp nuts, the discharge port of the feeding track 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com