Five-axis linkage laser 3D (Three Dimensional) metal printer

A five-axis linkage, printer technology, applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problem of ignoring the metal parts of 3D metal printers, and achieve the effect of fast printing and flexible laser head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

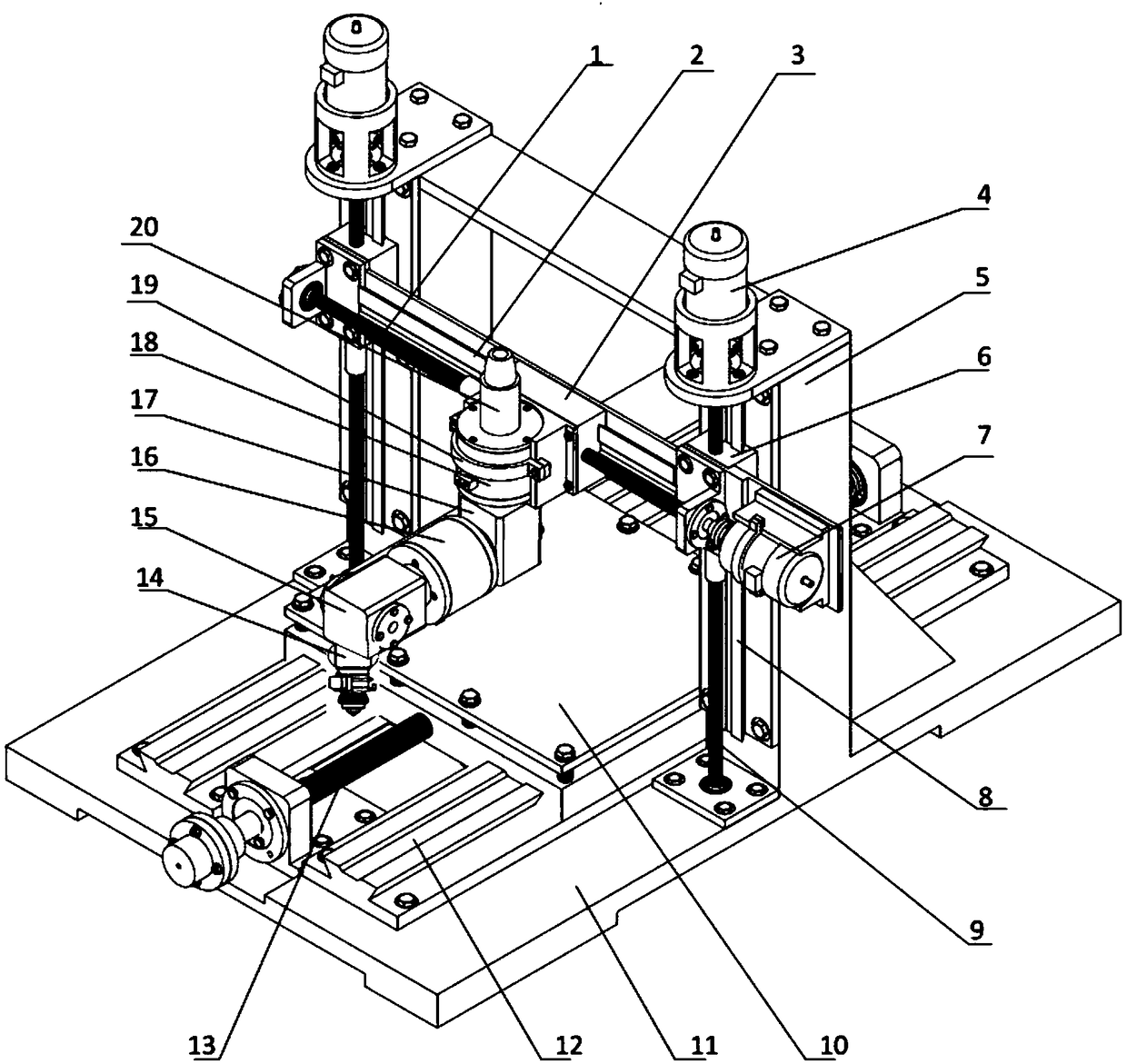

[0020] The present invention will be further explained below in conjunction with the drawings.

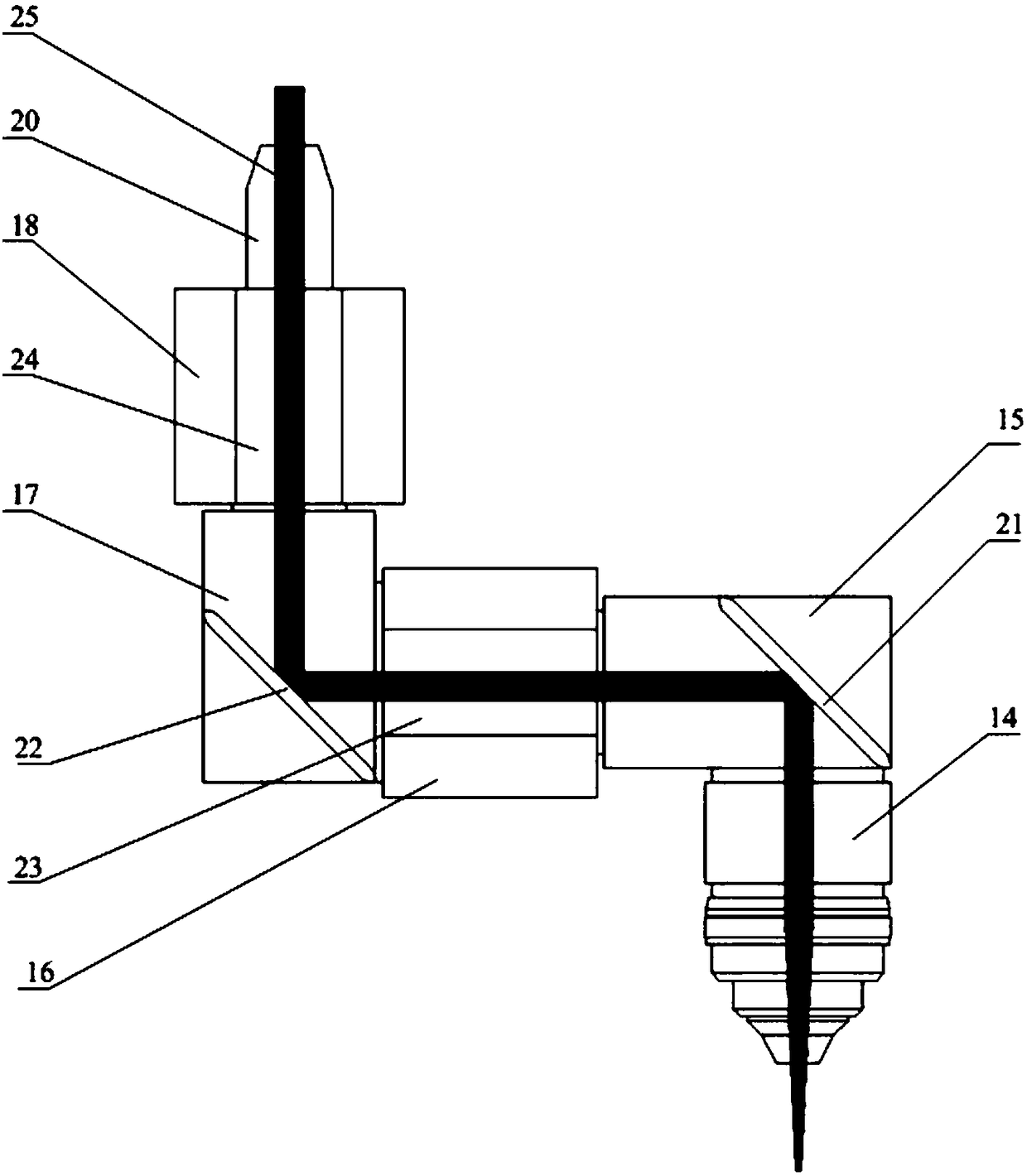

[0021] As shown in the figure, a five-axis linkage laser 3D metal printer of the present invention includes a base 11 on which a Y-axis sliding guide 12, a Y-axis ball screw 13, a gantry 5, a Y-axis sliding guide 12 and A worktable 10 is installed on the Y-axis ball screw 13, and the Y-axis ball screw 13 is driven by a Y-axis drive motor. The Y-axis ball screw 13 drives the worktable 10 to move along the Y-axis sliding guide 12, and the gantry 5 is installed Z-axis sliding guide 8, Z-axis ball screw 9, Z-axis sliding guide 8 and Z-axis ball screw 9 are equipped with Z-axis slider 6, Z-axis ball screw 9 is driven by Z-axis drive motor 4, Z-axis The ball screw 9 drives the Z-axis slider 6 to move along the Z-axis sliding guide 8. The Z-axis slider 6 is equipped with X-axis ball screw 1, X-axis sliding guide 2, X-axis ball screw 1 and X-axis sliding guide X-axis slider 3 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com