Automatic correction control system for strips

A control system and automatic deviation correction technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem of high market price, and achieve the effects of improving response speed, reducing cost, strong anti-interference and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

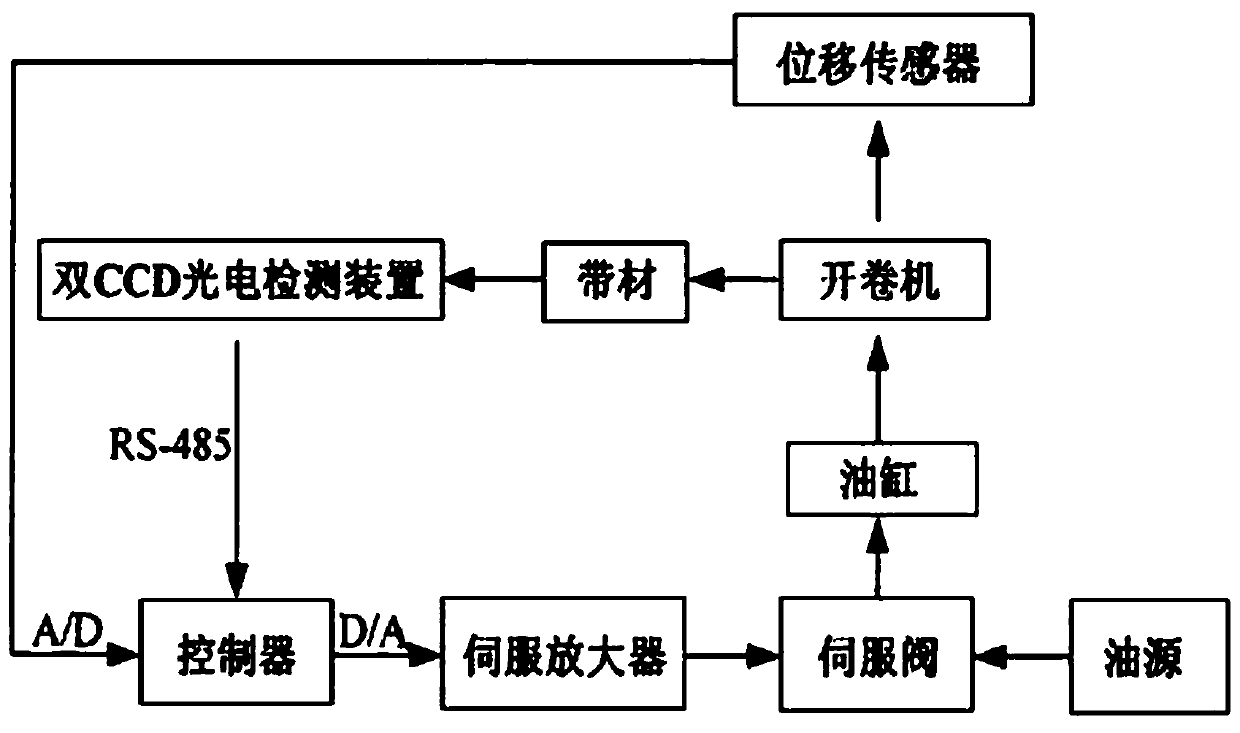

[0019] Such as figure 1 , in the automatic deviation correction control system, when the strip deviates from the center position of the unit during the transmission process, the CCD photoelectric detection device detects the real-time point information of the corresponding strip edge, and sends the point information to the single chip computer through RS-485 for processing , Calculate the actual deviation displacement of the strip, process the calculated deviation displacement through the PID algorithm, and send the deviation correction signal to the electro-hydraulic servo system through DIA conversion, and drive the deviation correction roller through the oil cylinder to perform deviation correction, thus forming a closed-loop control system.

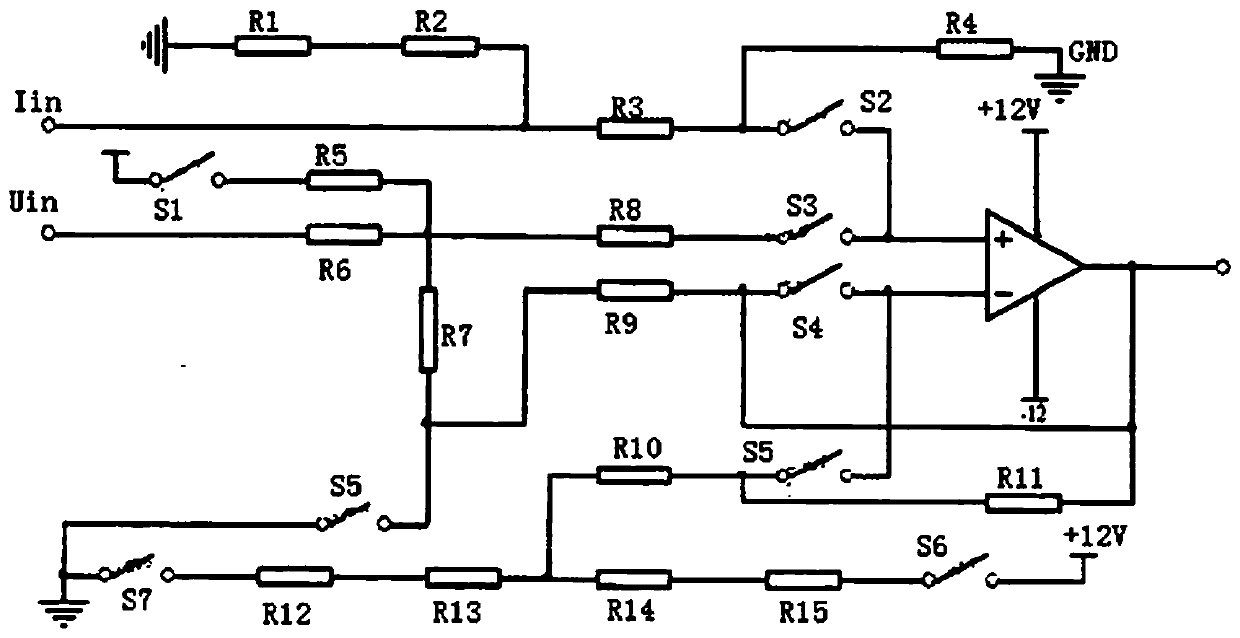

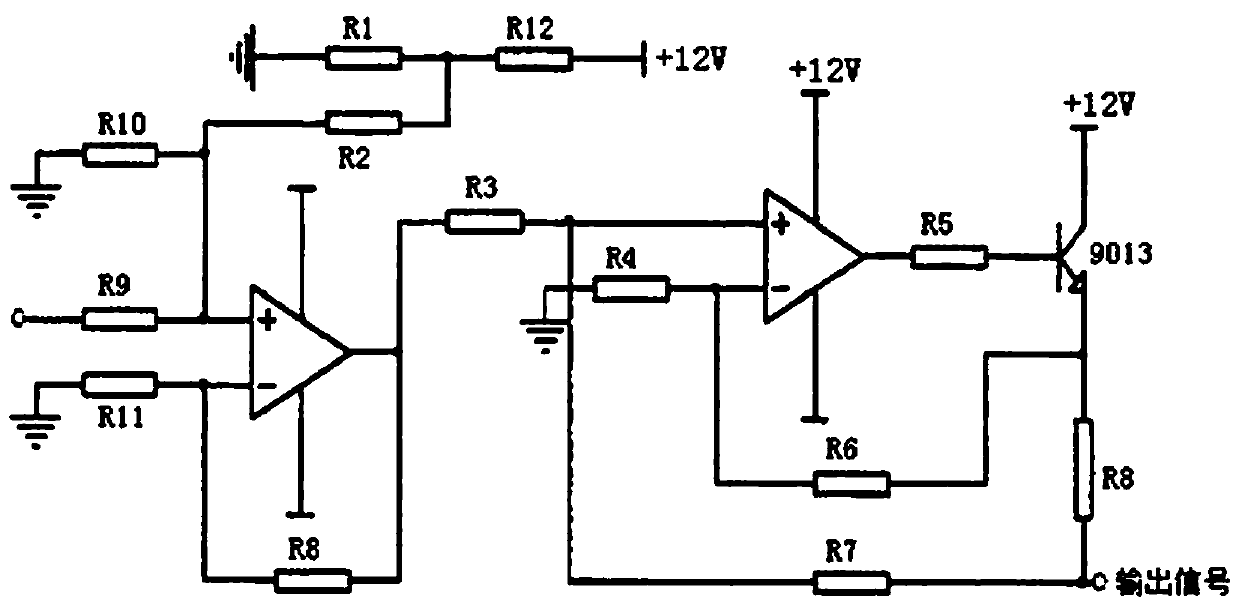

[0020] Such as figure 2 , The A / D conversion pre-signal processing circuit uses an operational amplifier as a voltage foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com