Agronomic land surface sprinkler

A sprinkler and surface technology, which is applied in the field of agronomic irrigation, can solve the problems of inability to irrigate large areas, easy scaling and clogging of drippers, and low efficiency of drip irrigation, and achieve good promotion and use value, reduce irrigation costs, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

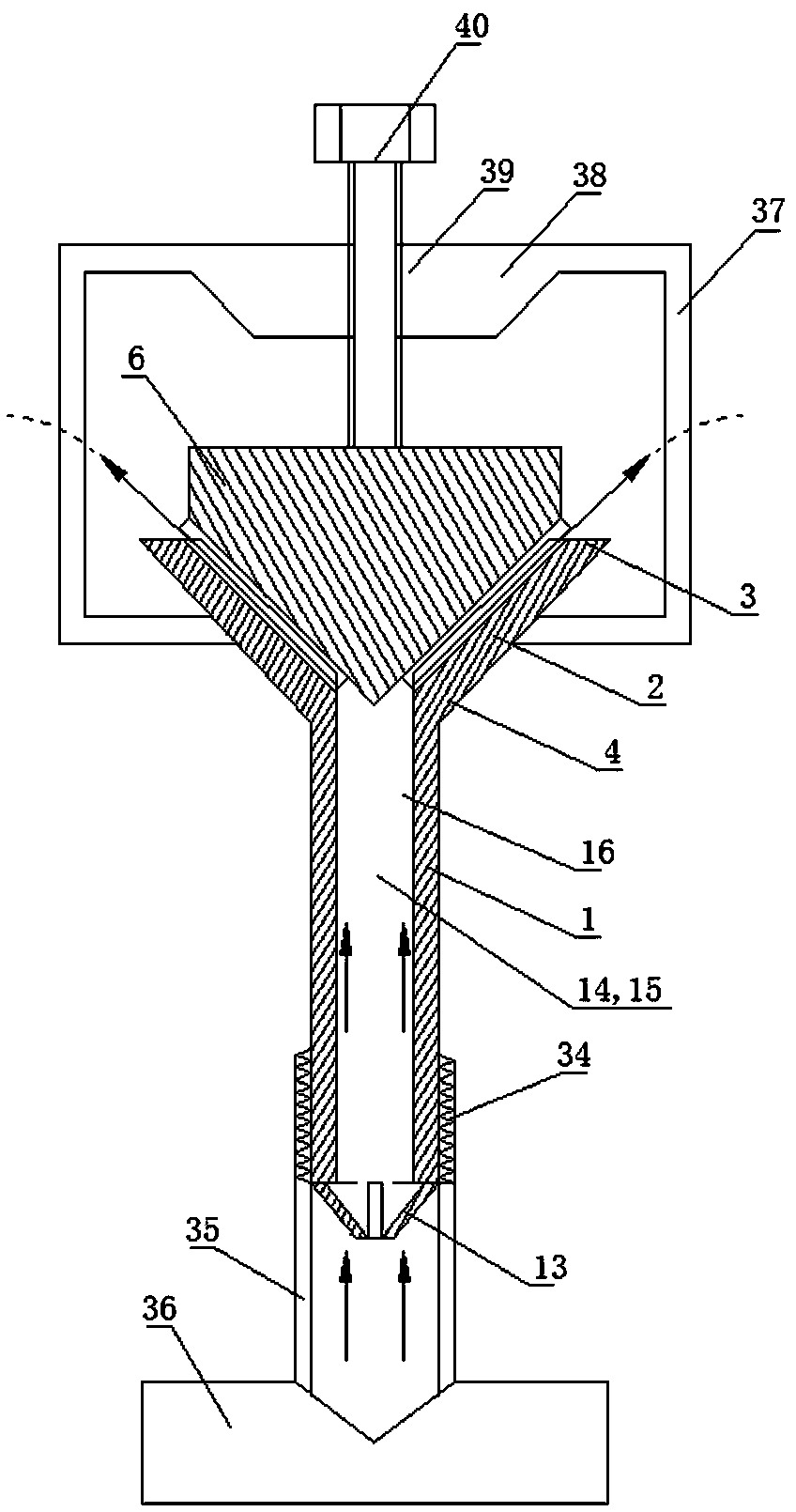

Embodiment 1

[0075] Design for axial feed mechanism:

[0076] The structure of the axial feed mechanism is: the periphery of the cone bucket bracket is fixedly connected with the peripheral frame integrated with the cone bucket bracket, the peripheral frame bulges upwards and surrounds the top cone, the raised top of the peripheral frame 37 is a closed entity, and the closed entity part 39 is provided with a screw hole, and the screw hole is on the same central axis as the conical bucket bracket and the top cone; the screw hole is pierced with a fastening bolt, the bolt head of the fastening bolt is upward, and the threaded body of the fastening bolt is screwed in. Screw hole, and screw out the screw hole downwards, the top is connected to the center of the top surface of the top cone, the fastening bolt squeezes the top cone downward, forcing the top cone to fit the cone bucket bracket, and the bottom dead center of extrusion is The bevel teeth of the cone bucket bracket and the cone teet...

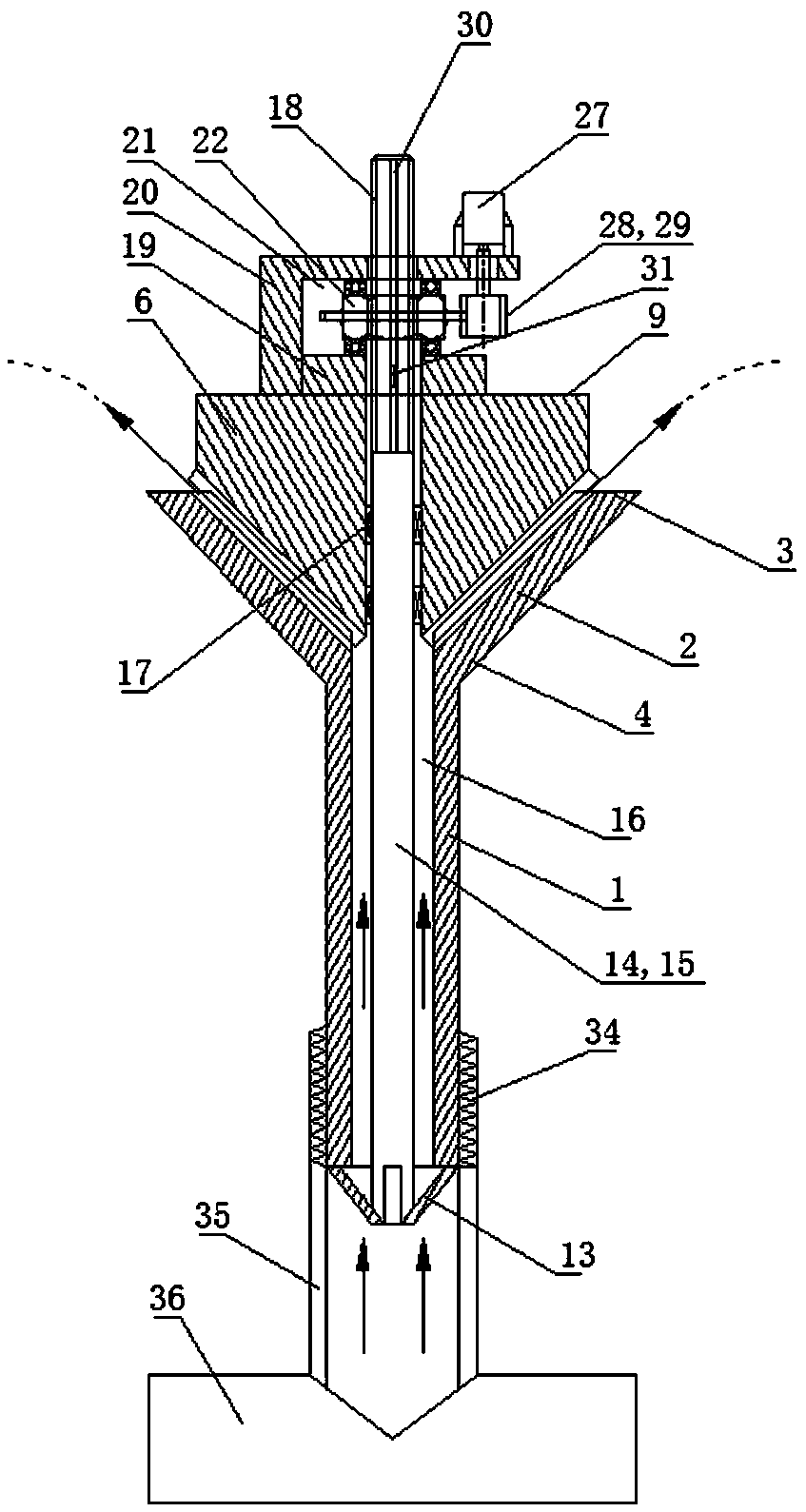

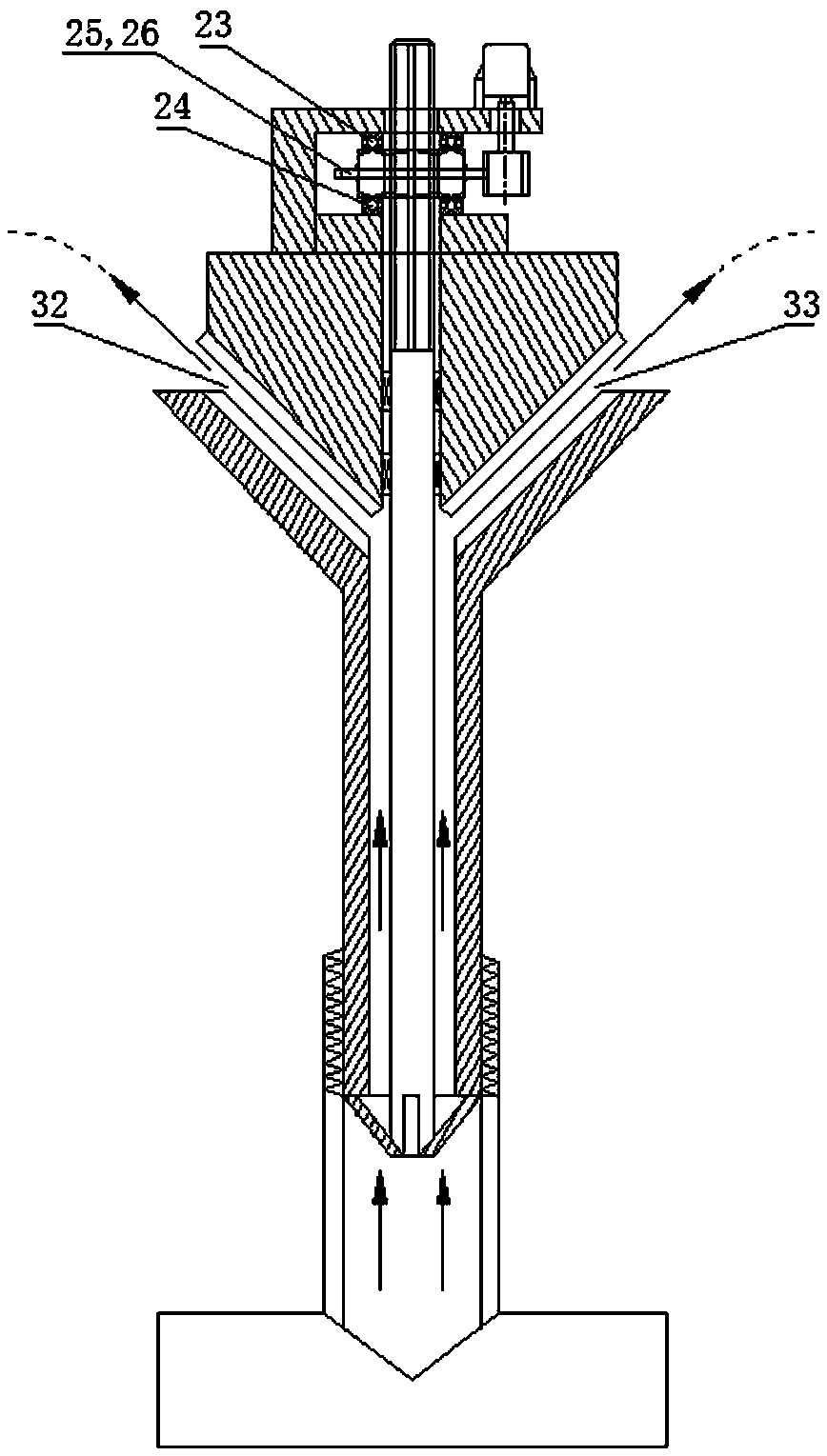

Embodiment 2

[0078] Another design for the axial feed mechanism:

[0079] The axial feed mechanism is driven by the central coaxial driving mechanism attached to the conical bucket bracket and the top cone respectively to make the top cone move up and down relative to the conical bucket bracket; the structure of the respectively attached central coaxial driving mechanism is: the top cone 6 sets There is a through hole 12 along the centerline direction, the through hole runs through the top cone,

[0080] The nozzle at the bottom end of the water spray pipe 1 is fixedly connected with a screw frame 13, and the screw rod 13 is fixedly connected with the water spray pipe 1 as a whole. Connect to the water spray pipe, extend upwards and protrude out of the top cone through the through hole of the top cone;

[0081] The middle and lower section of the screw rod 14 is set as a smooth section rod body 15, and the space between the smooth section rod body and the inner wall of the water spray pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com