Electromagnetic shielding telescopic structure and installation method thereof

A technology of electromagnetic shielding and telescopic structure, applied in the fields of magnetic field/electric field shielding, electrical components, screening cabinets, etc., can solve the problems of large difference in the width of expansion joints, difficult to achieve electromagnetic shielding, front and rear position errors, etc., and achieve fast installation speed. , Not easy to loosen, reduce the weight of the structure and the effect of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

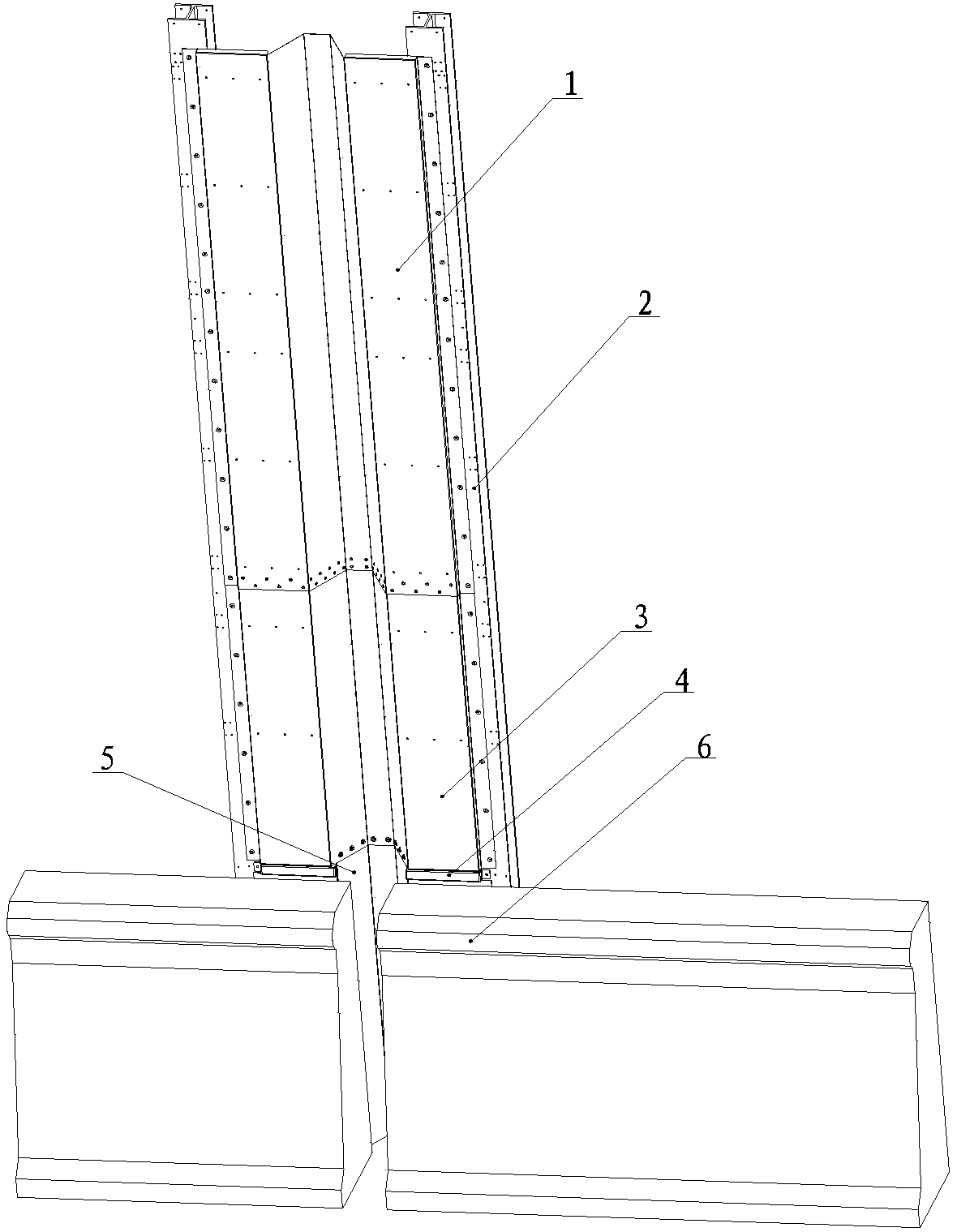

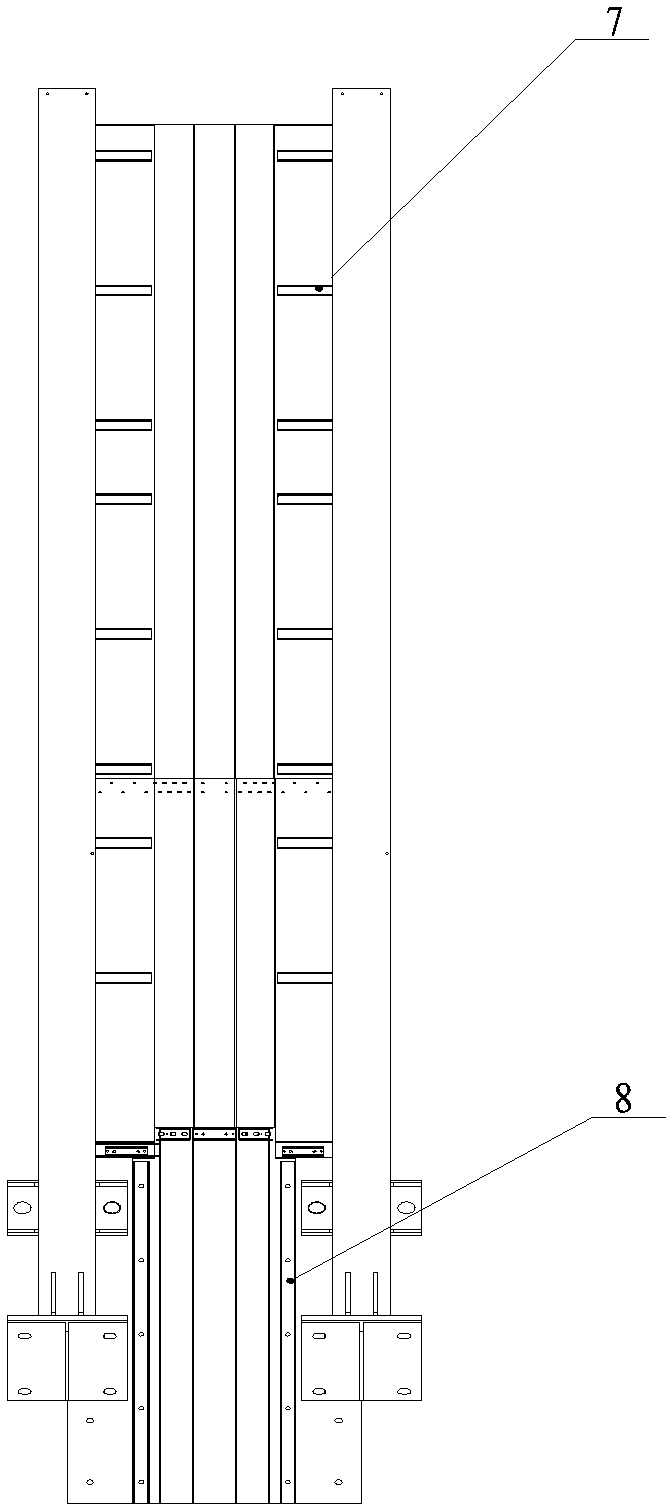

[0021] Example 1, such as Figure 1-2 As shown, this embodiment discloses a telescopic structure for electromagnetic shielding. The structure includes two columns 2 installed vertically on both sides of the expansion joint on the fixed foundation 6, and between the two columns 2 from bottom to top The lower shielding plate 5, the middle shielding plate 3 and the upper shielding plate 1, which are made of elastic materials and have electromagnetic shielding effects, are installed in sequence. The shielding plate 3 is fixedly connected, and is fixedly connected to the fixed base 6 through the rear shielding bead 8, and the middle shielding plate 3 and the upper shielding plate 1 are connected by rivets to form a telescopic shielding unit.

[0022] In this embodiment, the horizontal cross-sectional shape of the lower shielding plate, the middle shielding plate and the upper shielding plate is a stretched shape. Between the two columns 2, more than three support plates 7 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com