Bidirectional synchronous paper inserting intelligent robot for power distribution station motor

An intelligent robot, two-way synchronization technology, applied in the direction of laying solid insulation, etc., can solve the problems of consuming a lot of time and energy and labor costs, low production efficiency, inconvenient use, etc., to improve the quality of the motor, save labor costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

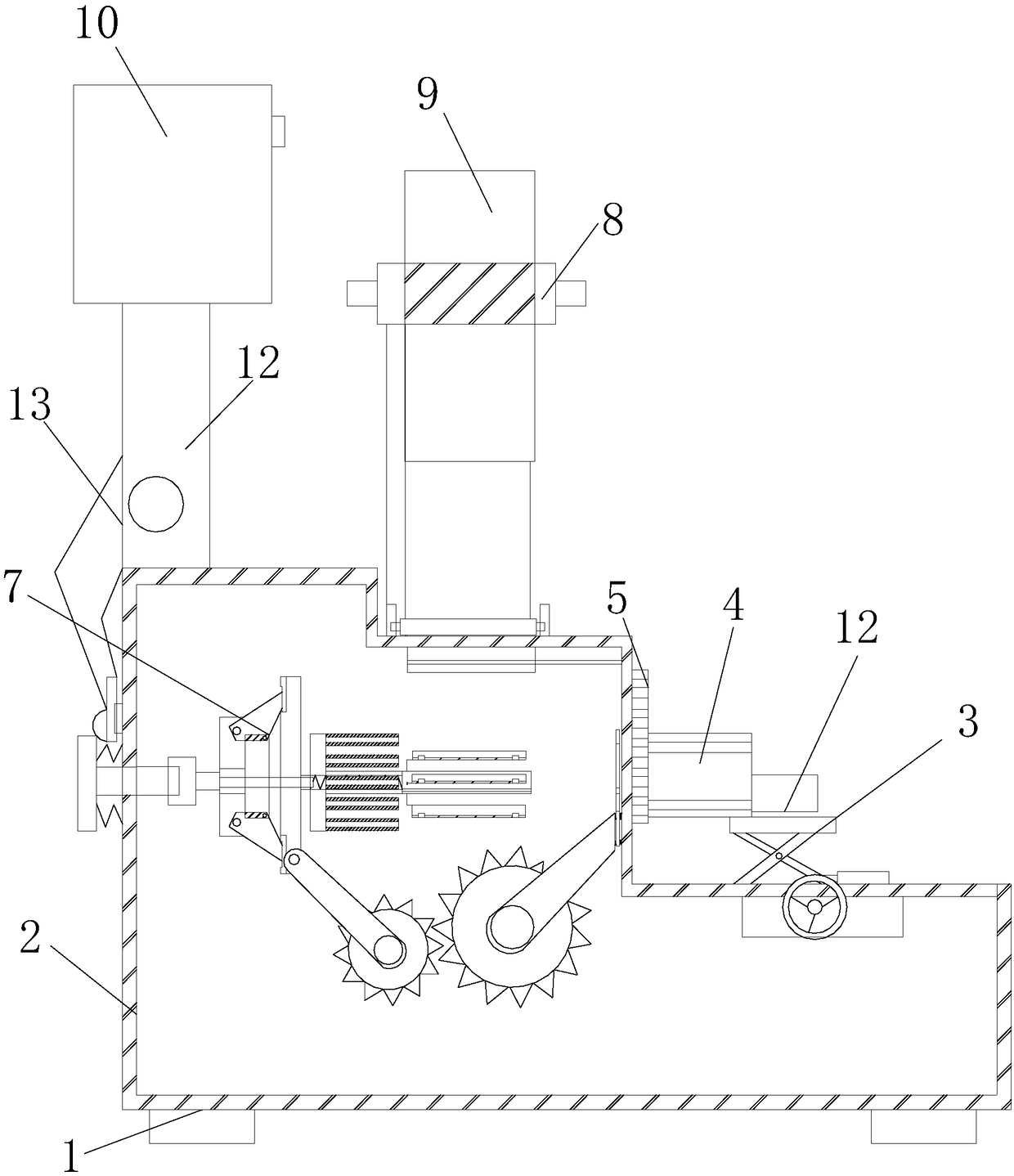

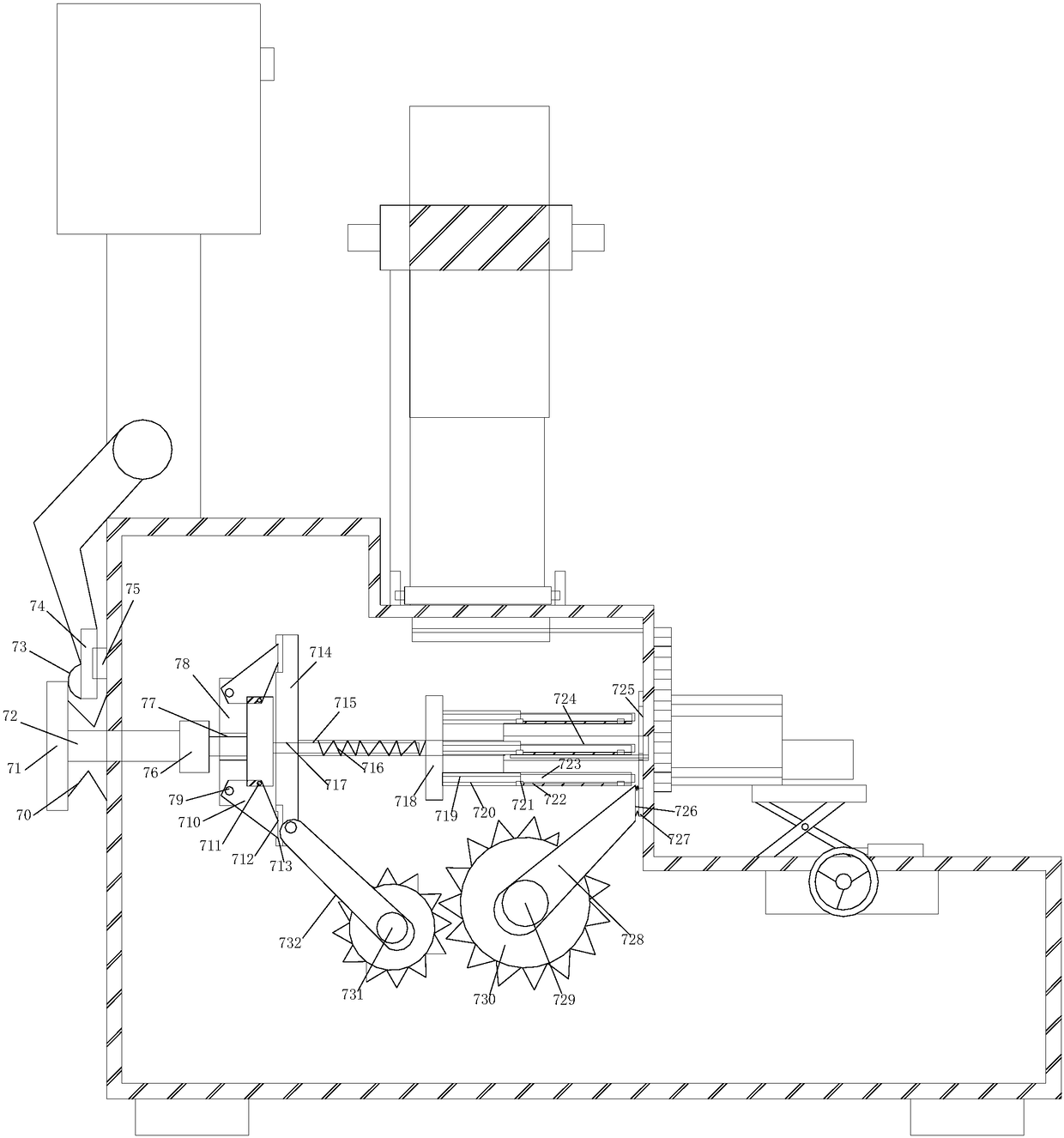

[0026] see Figure 1-Figure 5 , the present invention provides a kind of electric motor two-way synchronous paper-inserting intelligent robot for power distribution station: its structure comprises shock-absorbing pad 1, box body 2, support frame 3, motor rotor 4, support gear 5, power gear 6, synchronous paper-inserting Device 7, fixed frame 8, insulating paper 9, machine head 10, monitor 11, support column 12, movable arm 13, rotating stick 14, rotating shaft 15, control box 16;

[0027]The shock-absorbing foot pad 1 is arranged at the bottom of the box body 2 and is connected to the ground. The upper part of the box body 2 is stepped and connected to the support frame 3. The support frame 3 is provided with the front end of the box body 2 and is connected to the motor rotor. 4 support connection, the motor rotor 4 is connected with the support gear 5 slot and is rotationally connected with the support gear 5 through the power gear 6, the support gear 5 is installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com