Modularized surface-mount type permanent magnet rotor

A permanent magnet, surface-mounted technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, magnetic circuit shape/style/structure, etc. Problems such as difficult processing of permanent magnets, to avoid the decline of glue adhesion, simple processing, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

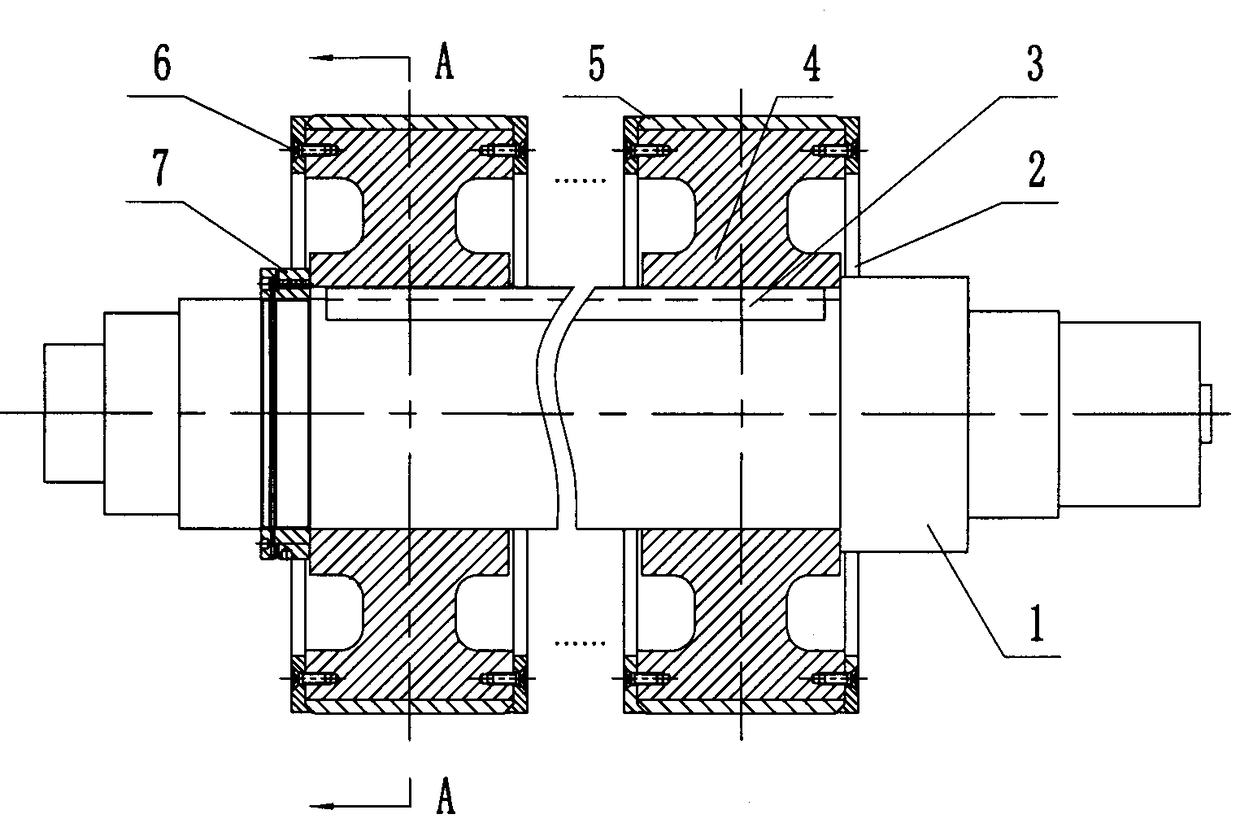

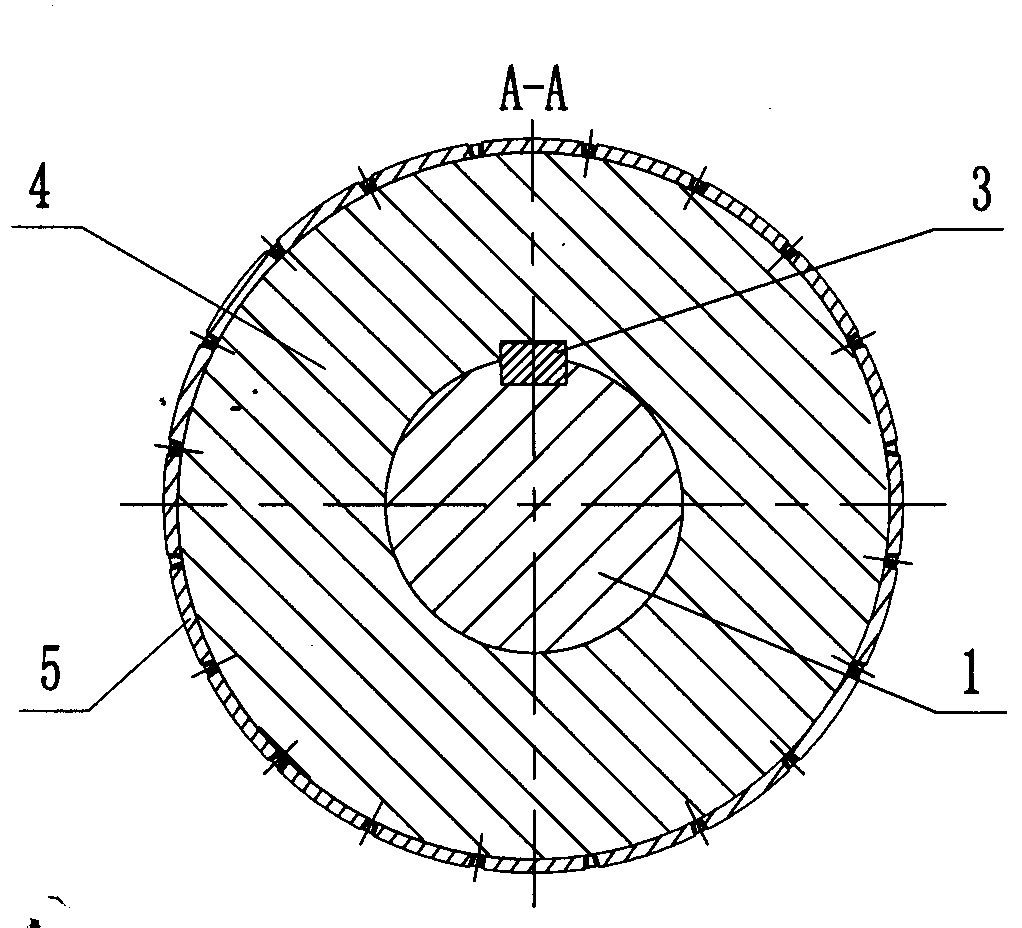

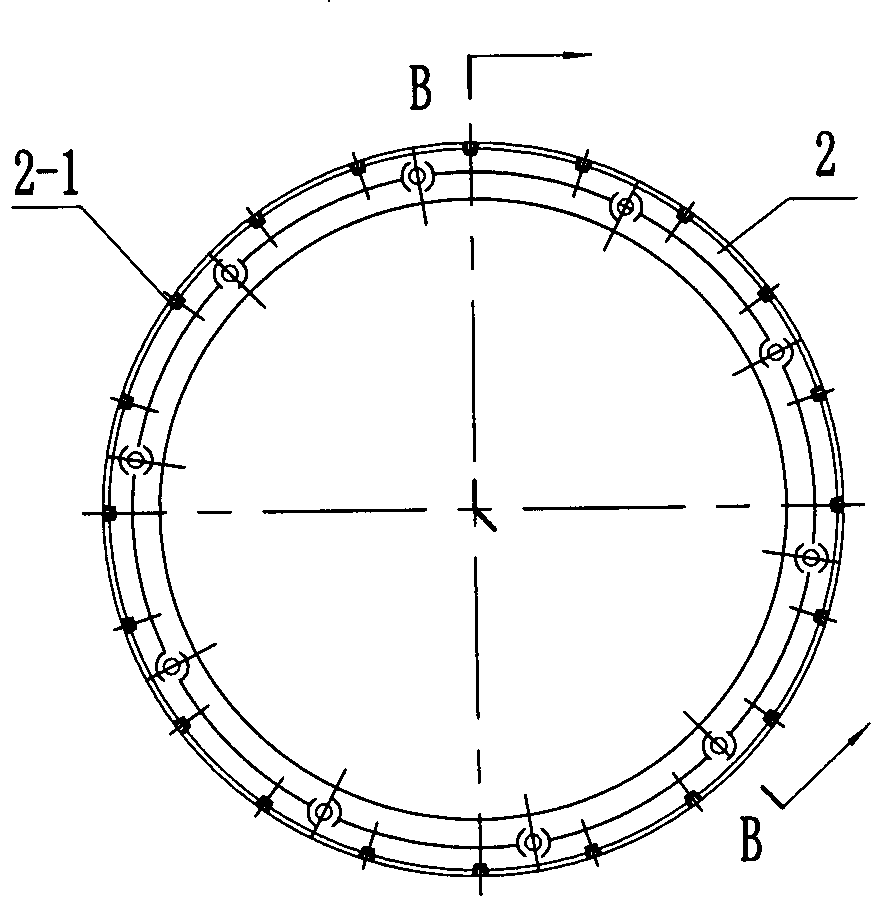

[0021] according to Figure 1-7 The specific structure of the present invention will be described in detail. The modular surface-mounted permanent magnet rotor includes a main shaft 1 and components such as a rotor module unit assembled on the main shaft 1 by means of a flat key 3 and a lock nut 7 . Wherein, at least one rotor module unit is assembled on the main shaft 1 . Each rotor module unit can be composed of a rotor sleeve 4 assembled together, a plurality of permanent magnets 5 , two clips 2 and fasteners 6 to form an integrated structure. Therefore, according to the high torque of the motor, the number of rotor module units can be assembled arbitrarily, and the output torque of the motor can be increased, which solves the technical problem that the surface-mounted permanent magnet cannot be firmly fixed due to the high torque required by the motor. Fasteners 6 may consist of countersunk screws. The outer periphery of the buckle 2 is provided with conical stops evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com