Paper coating machine and paper coating method of single pole plate

A plate and paper-covering technology, which is applied in the direction of lead-acid battery electrodes, electrode carriers/collectors, sustainable manufacturing/processing, etc., can solve operator and on-site environmental pollution, high energy consumption in production processes, and high labor intensity for workers and other problems, to achieve the effect of eliminating lead mud and environmental pollution, reducing lead dust, and consistent water content inside and outside the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

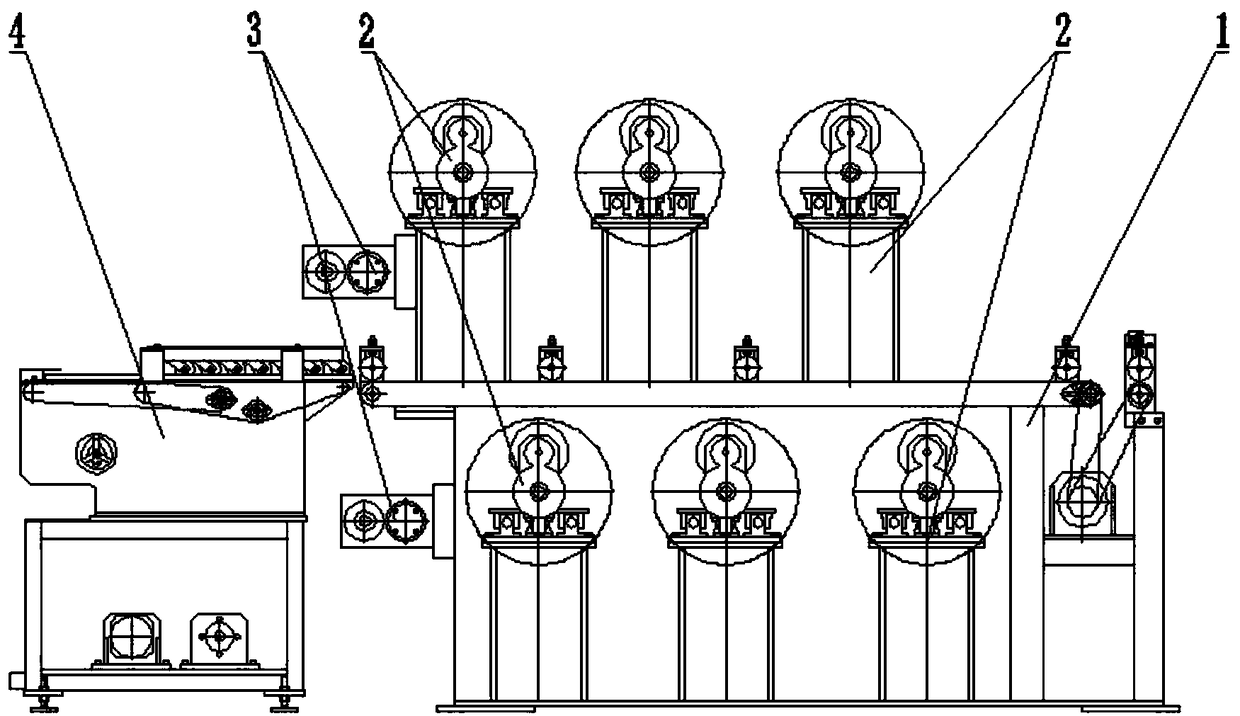

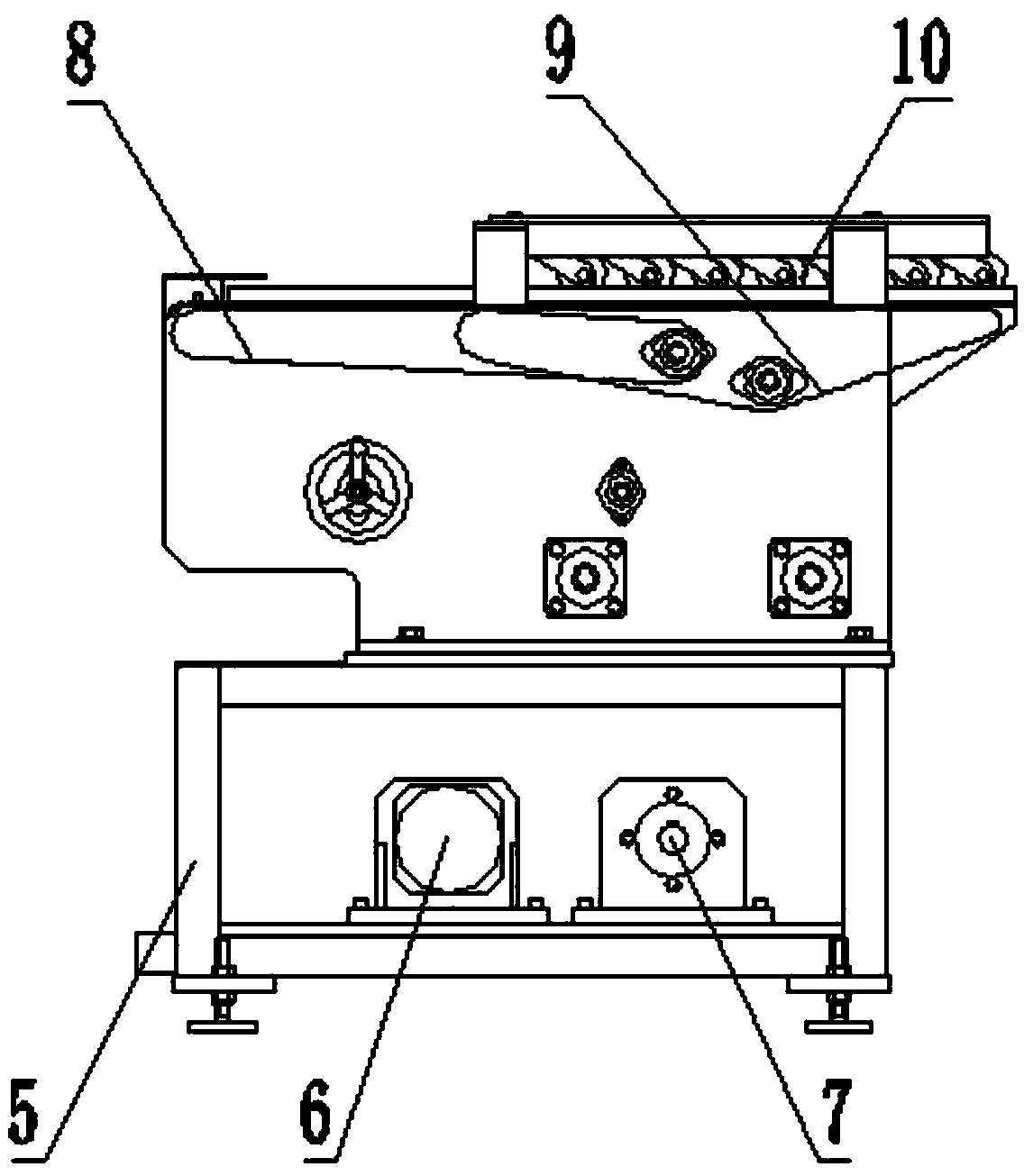

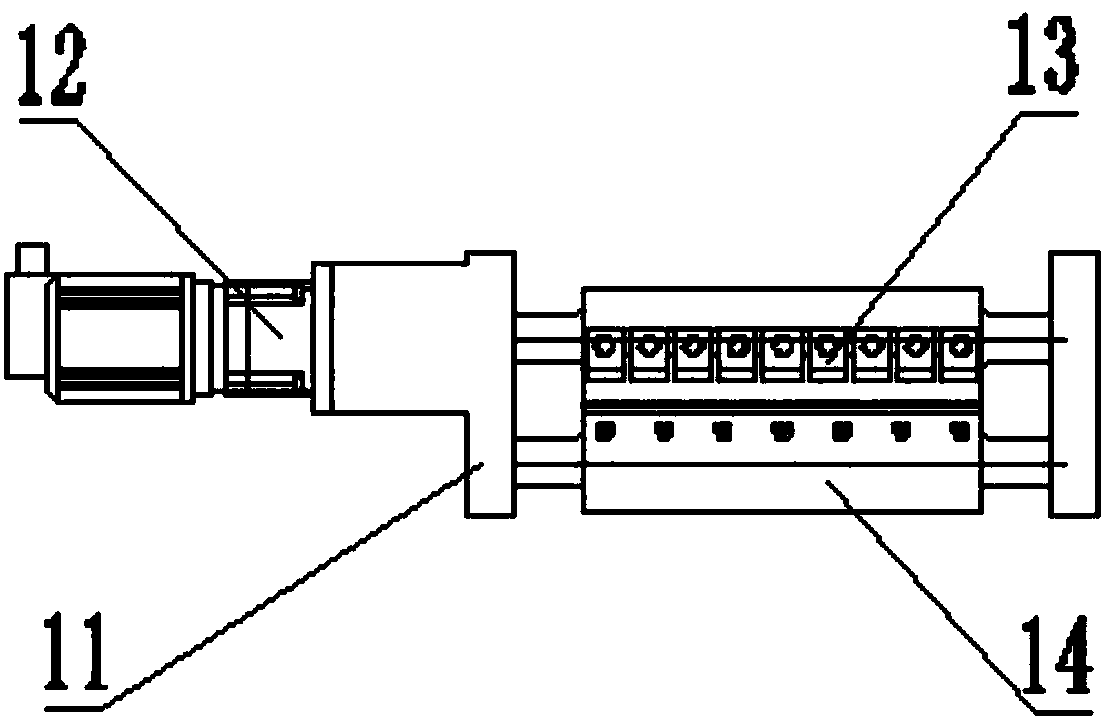

[0034] refer to Figure 1-5 , a specific embodiment of the present invention includes a coated paper coating and breaking mechanism 1, a number of coated paper feeding devices 2 are installed on the fourth frame body 21 of the coating paper coating and breaking mechanism 1, The cardboard paper supply device 2 is respectively located above and below the synchronous toothed conveyor belt 23 of the coated paper coating and breaking mechanism 1, and the fourth frame body 21 of the coated paper coating and breaking mechanism 1 is installed with Two dotted line cutting devices 3 for coated paper, the two dotted lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com