Efficient condenser

A condenser and high-efficiency technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of low condensation efficiency, large size, and high cost of the condenser, and achieve improved condensation efficiency, improved condensation efficiency, and heat dissipation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

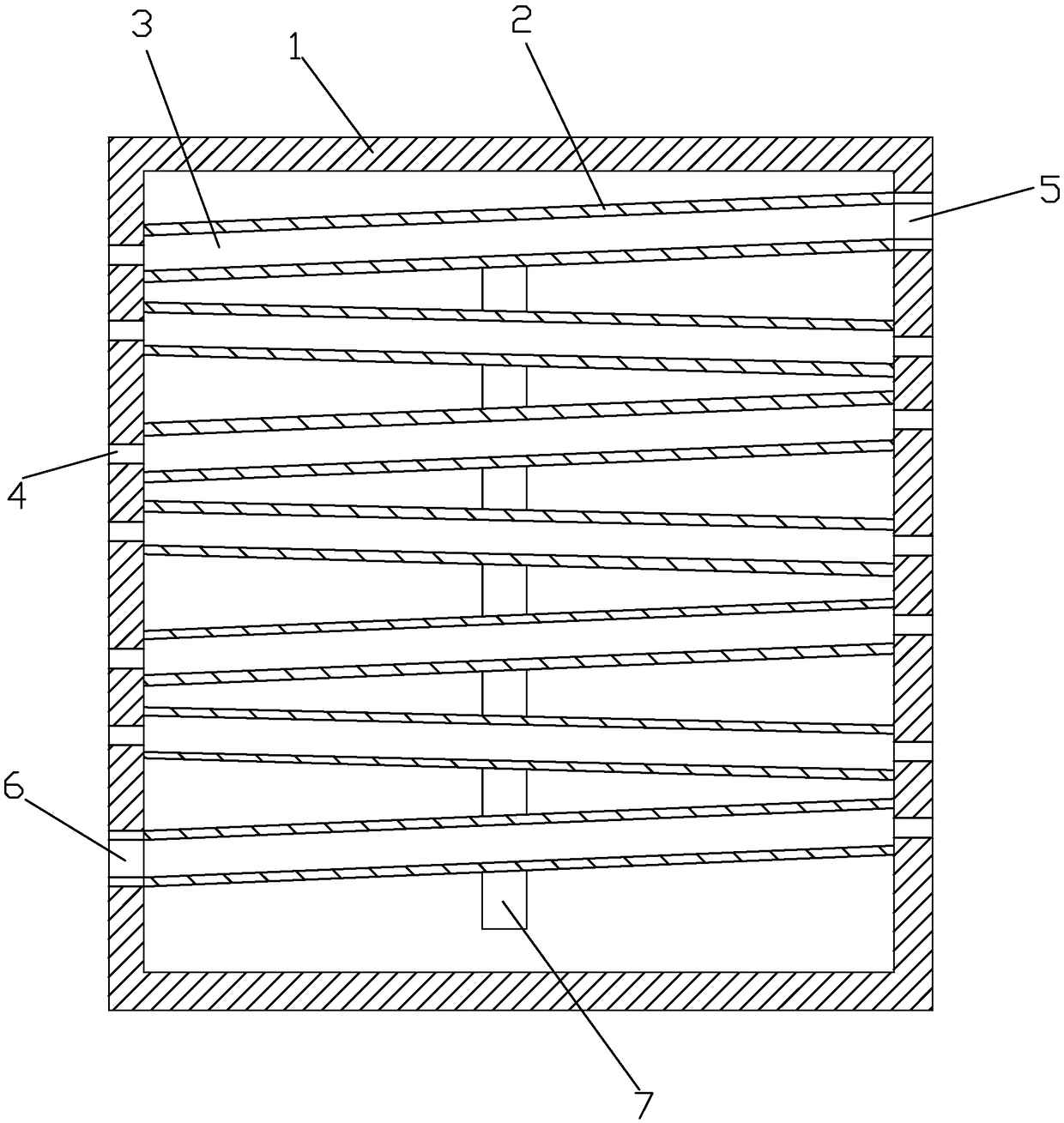

[0022] A high-efficiency condenser provided in this embodiment has a structure such as figure 1 shown.

[0023] The high-efficiency condenser includes an outer shell 1 and several inner shells 2 evenly distributed inside the outer shell 1 from top to bottom. The inner casing 2 is arranged obliquely and the included angle range with the horizontal direction is 15-30°, and the inclination directions of the inner casings 2 adjacent up and down are opposite. A connecting pipe 7 communicating with each other is provided between the inner shells 2, the uppermost inner shell 2 is provided with a liquid inlet 5, and the lowermost inner shell 2 is provided with a liquid outlet 6, and the liquid inlet 5 and The liquid outlet 6 is respectively provided with an automatic liquid inlet valve and an automatic liquid outlet valve.

[0024] The two sides of the inner shell 2 are open and connected with the outer shell 1 to form a refrigerating chamber 3, the refrigerating chamber 3 is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com