Air purification defense system

A defense system and air purification technology, applied in air conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve problems such as loud noise, limited water volume of fog cannons, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

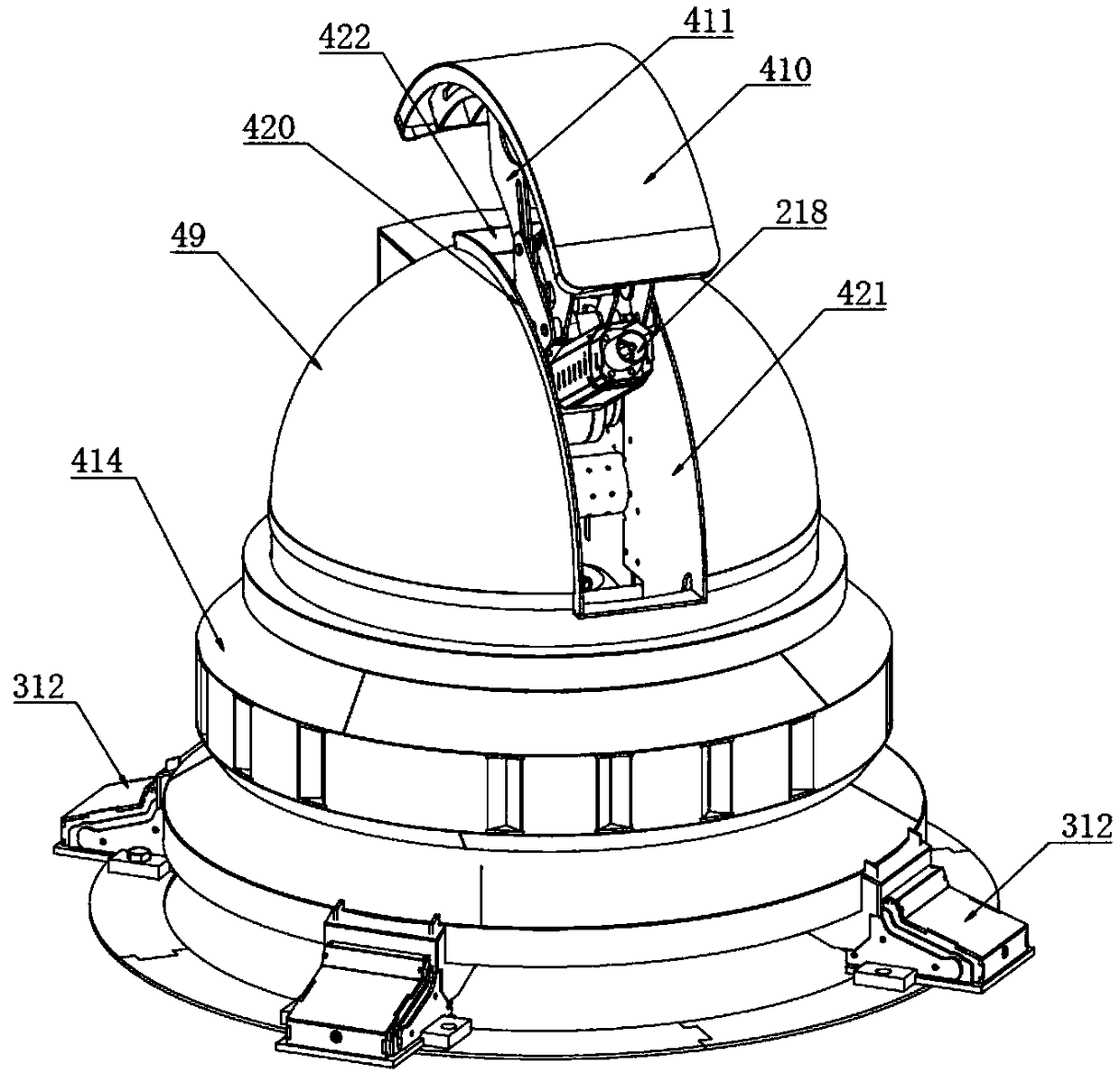

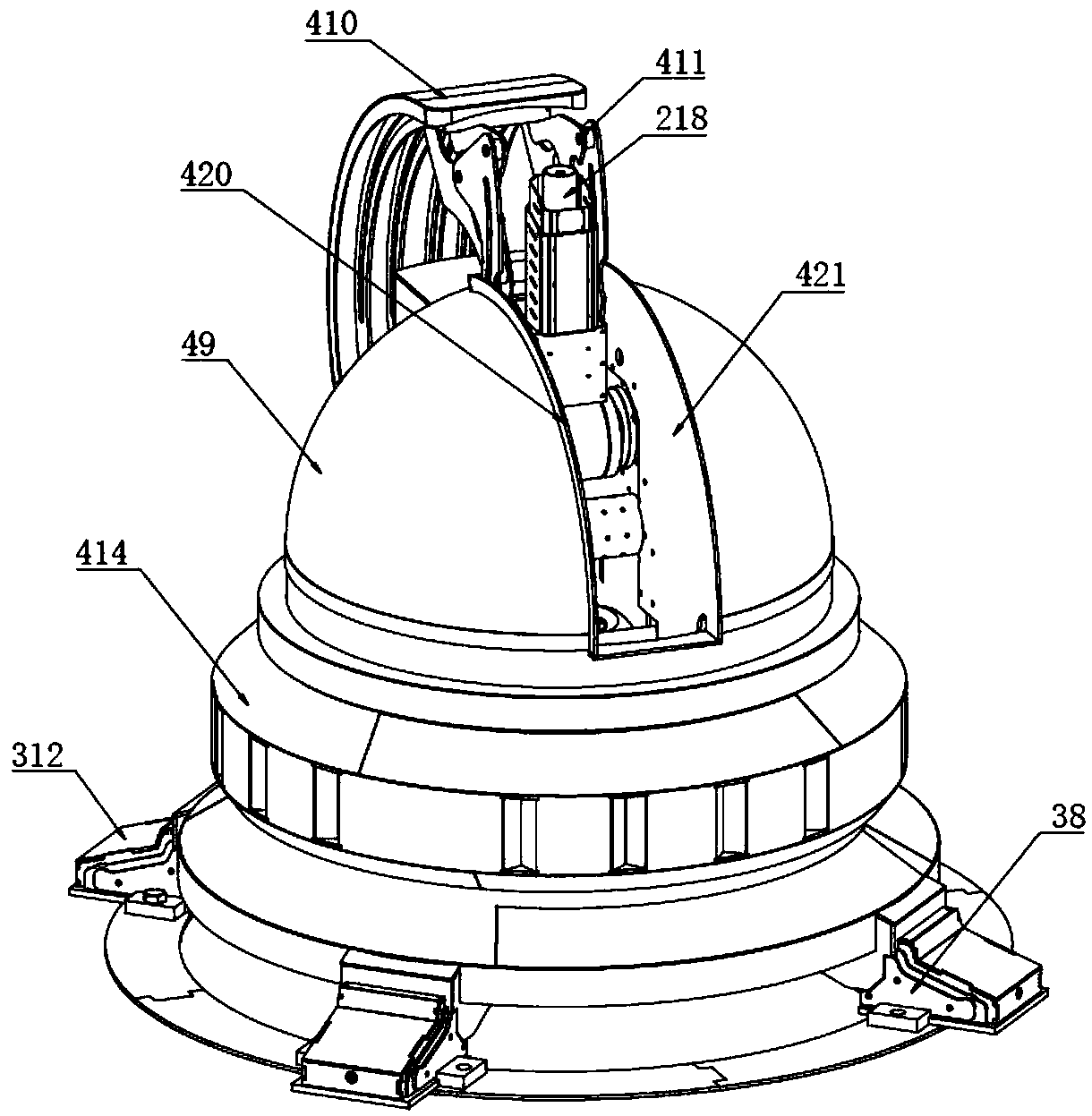

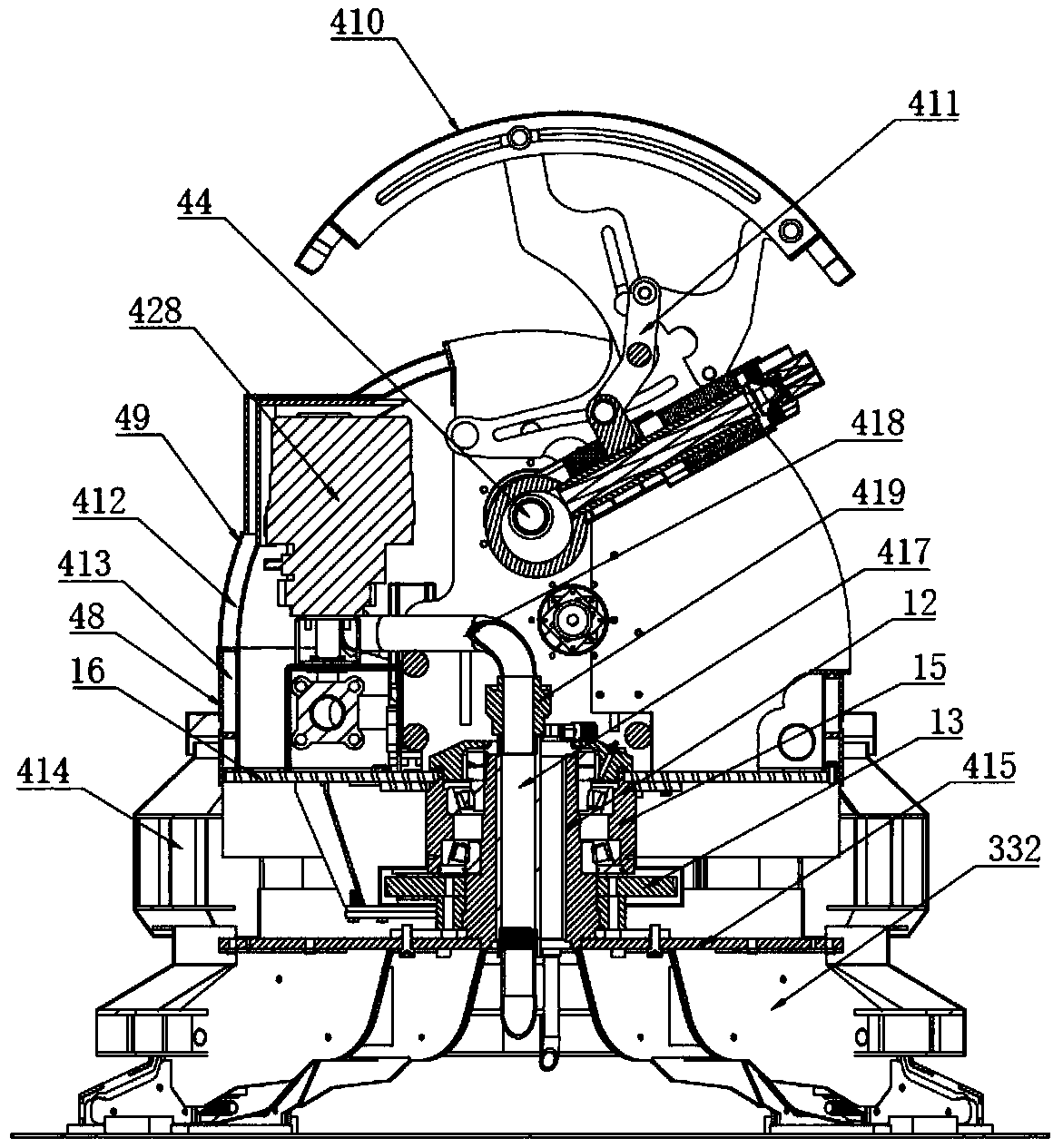

[0188] Embodiment 1: as Figure 1 to Figure 18 As shown, an air purification defense system includes a water supply device and a terminal. The terminal includes a rotary support mechanism, a fluid injection mechanism and a fluid supply pipeline. The rotary support mechanism includes a base 11, a main shaft 12, a main gear 13, and a drive gear 14. Oil cylinder housing 15, rotating platform 16 and gear drive mechanism 17. The main shaft 12 is vertically arranged on the upper surface of the base 11. The main shaft 12 is provided with a main shaft through hole penetrating up and down. The main gear 13 is sleeved and fixed On the outer side of the main shaft 12, the oil cylinder housing 15 is sleeved on the outer side of the main shaft 12 through the main bearing 18, the rotating platform 16 is sleeved and fixed on the oil cylinder housing 15, the driving gear 14 meshes with the main gear 13, and the The gear drive mechanism is arranged on the rotating platform 16, and the gear dri...

Embodiment 2

[0237] Embodiment 2, as a kind of improved scheme of embodiment 1, such as Figure 20 to Figure 22 As shown, the sliding shaft driving mechanism is a hydraulic sliding shaft driving mechanism, and the hydraulic sliding shaft driving mechanism includes a fixed shaft 314, a hydraulic cylinder 316, a coupling 318 and a hydraulic system 317, and the hydraulic system 317 is arranged on the bottom horizontal plate 31, the two ends of the fixed shaft 314 are respectively connected with the two lower support plates 32, the hydraulic system includes an oil storage tank, a hydraulic pump, a one-way valve and a reversing valve, the oil storage tank, hydraulic pump, The one-way valve and the reversing valve are connected in turn through the oil inlet pipeline, the oil storage tank and the reversing valve are connected through the oil return pipeline, the reversing valve and the hydraulic cylinder 316 are connected through two hydraulic pipelines, and the hydraulic cylinder 316 The cylinde...

Embodiment 3

[0240] Embodiment 3, as another kind of improved scheme of embodiment 1, such as Figure 23 and Figure 24 As shown, the sliding shaft driving mechanism is an electric sliding shaft driving mechanism, and the electric sliding shaft driving mechanism includes a leg driving motor controller 321, a leg driving motor 319, a connecting rod 320 and a link 318, and the legs The drive motor 319 is arranged on the bottom horizontal plate 31, the leg drive motor 319 is connected with the leg drive motor controller 321, the leg drive motor 319 is connected with one end of the connecting rod 320, the other end of the connecting rod 320 One end is connected with one end of the coupling part 318 , and the other end of the coupling part 318 is connected with the sliding shaft 35 , and the coupling part 318 is a bolt connecting the sliding shaft 35 and the connecting rod 320 . The terminal controller is connected with the leg drive motor controller 321 through a signal line;

[0241] The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com