A kind of mechanical transmission drive device

A technology of driving device and mechanical transmission, which is applied in the direction of transmission device, mechanical equipment, rider drive, etc. It can solve the problems of uneven instantaneous speed, vibration and noise, high manufacturing and installation precision, and achieve less power loss and reasonable Speed, the effect of guaranteed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

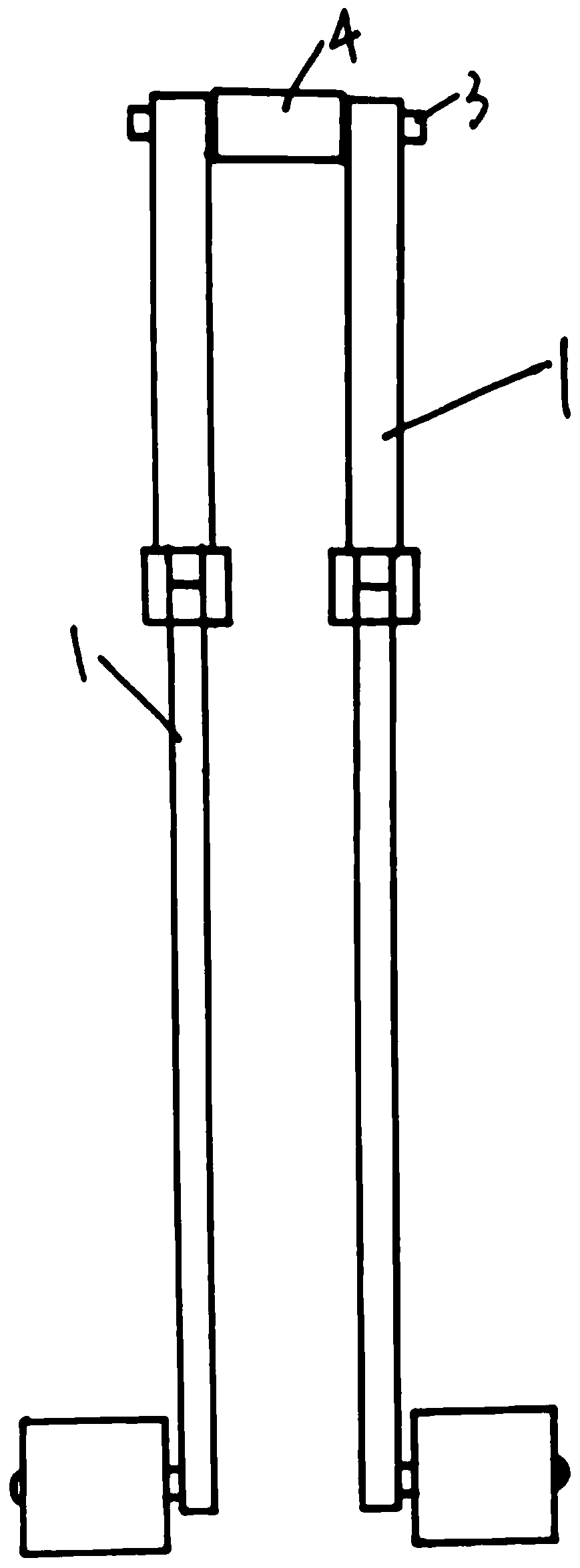

[0018] A mechanical transmission driving device, comprising two sets of levers 1, two sets of transmission mechanisms 2, an intermediate shaft 3, and a hollow rolling shaft 4. The hollow rolling shaft 4 is installed on the intermediate shaft 3, and the two sets of levers 1 are respectively installed on both ends of the intermediate shaft 3 through the transmission mechanism 2.

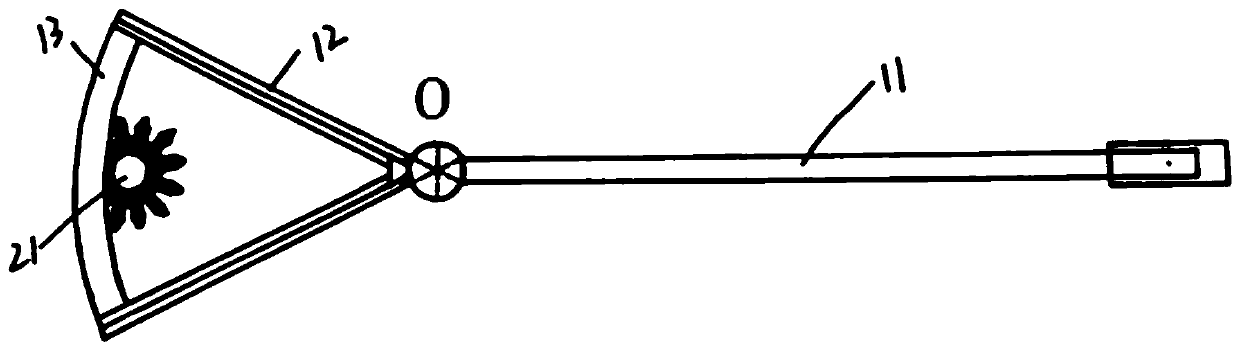

[0019] Described lever 1 comprises a power arm 11, two resistance arms 12 and an internal gear arc 13, and two resistance arms 12 are connected with power arm 11 at the fulcrum, and power arm 11 and resistance arm 12 rotate synchronously around the fulcrum, The fulcrum remains relatively stationary with the intermediate shaft 3 . The distal ends of the resistance arms 12 are respectively connected to the two ends of the inner tooth arc 13, and the center of the inner tooth arc 13 coincides with the fulcrum.

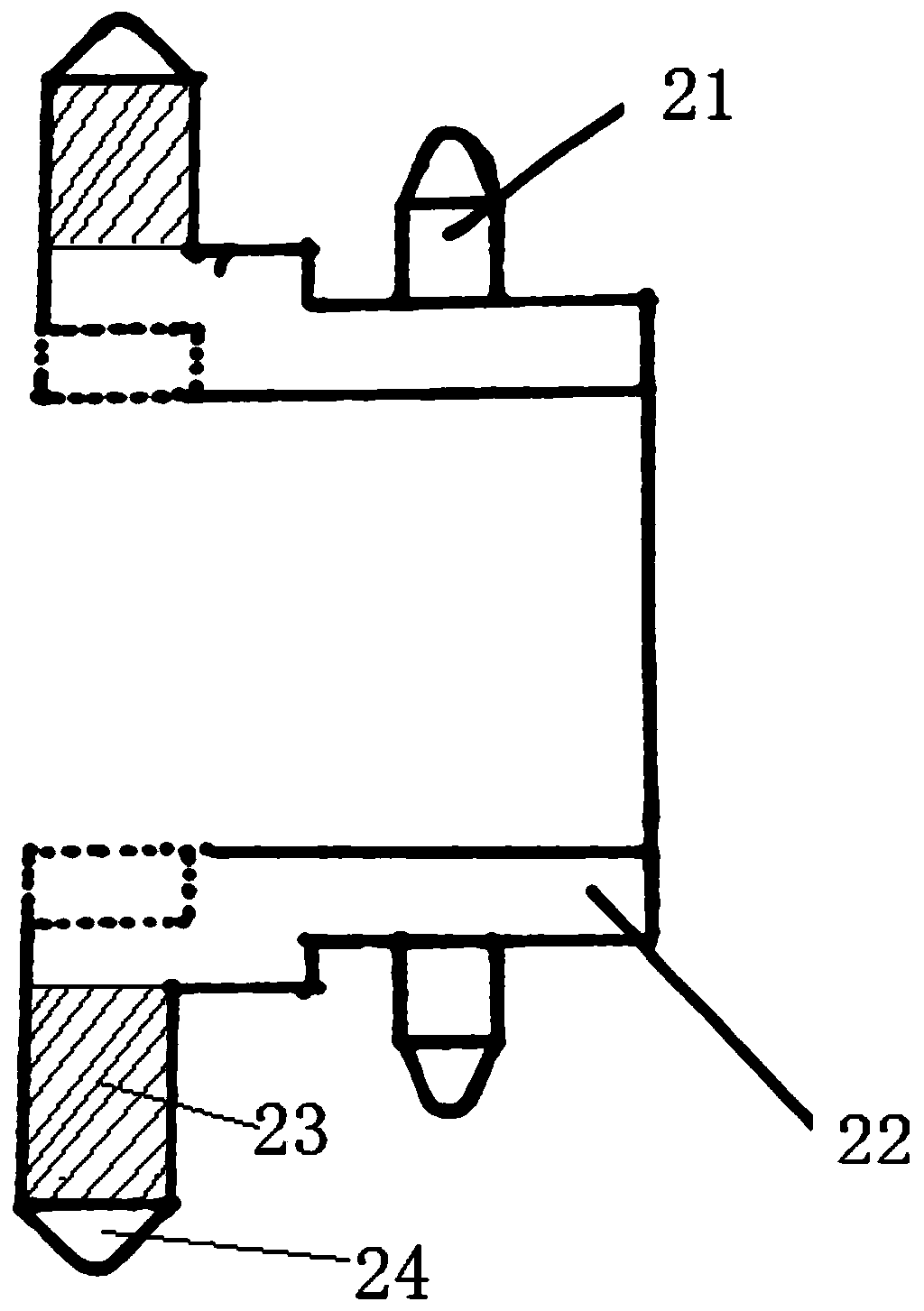

[0020] The transmission mechanism 2 includes a first gear 21, an inner gear ring 22 coaxially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com