Classified acid pickling acidification method of horizontal well

A horizontal well and pickling technology, which is applied in the direction of earthwork drilling, wellbore/well parts, cleaning equipment, etc., can solve the problems of poor pertinence and unsatisfactory acidizing effect, and achieve the effect of simple structure and convenient on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

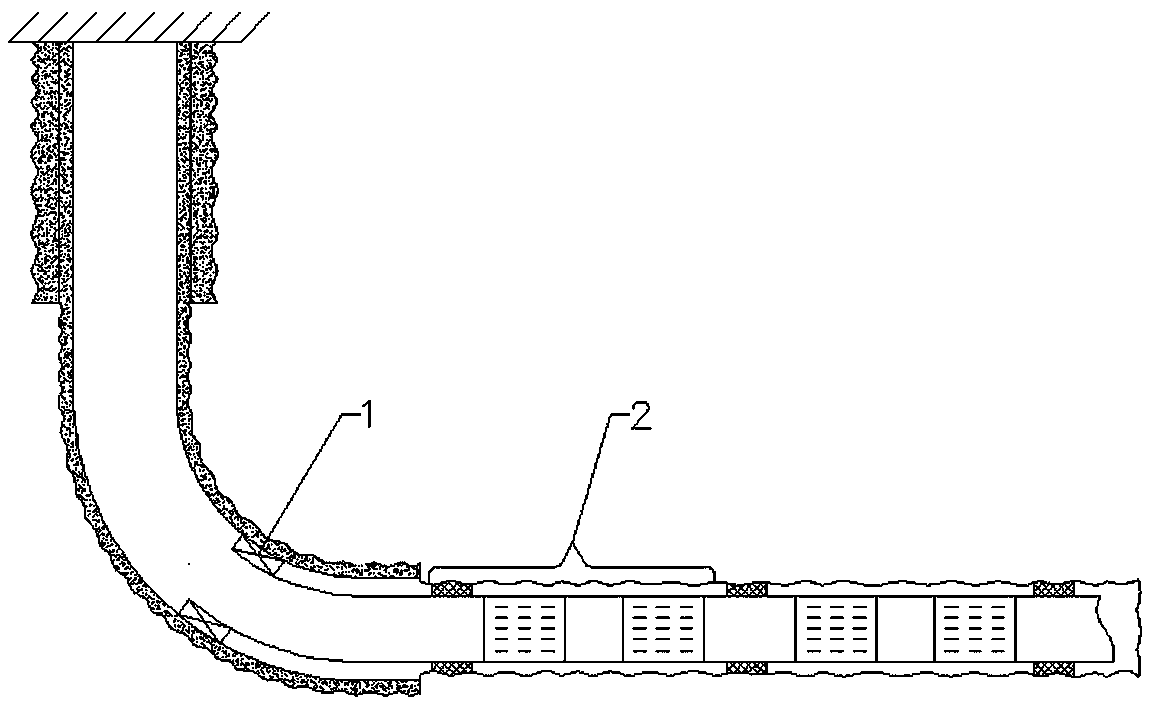

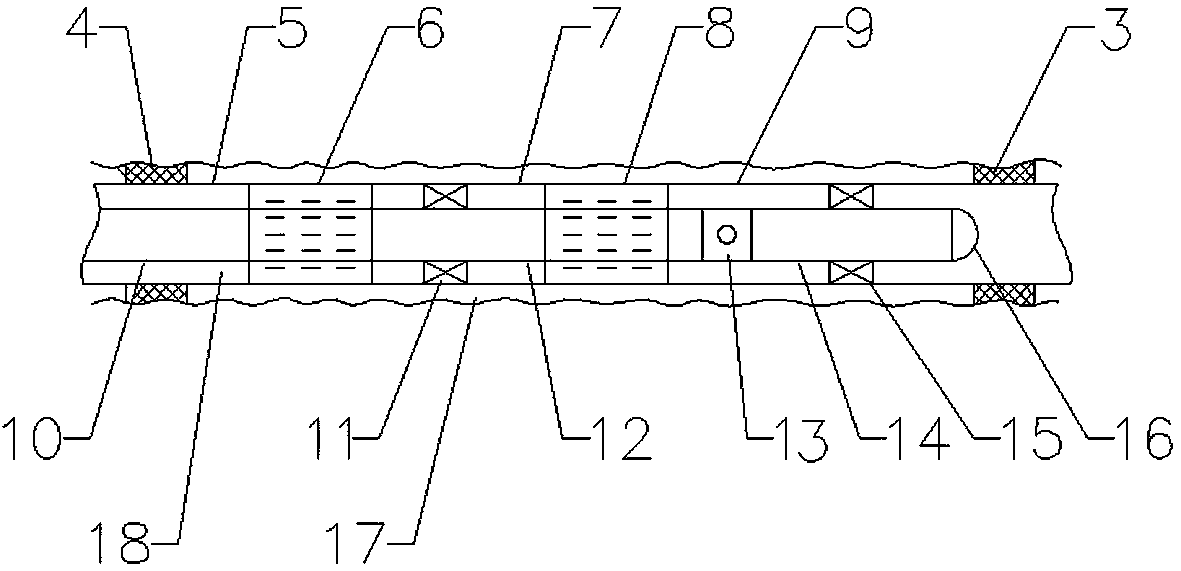

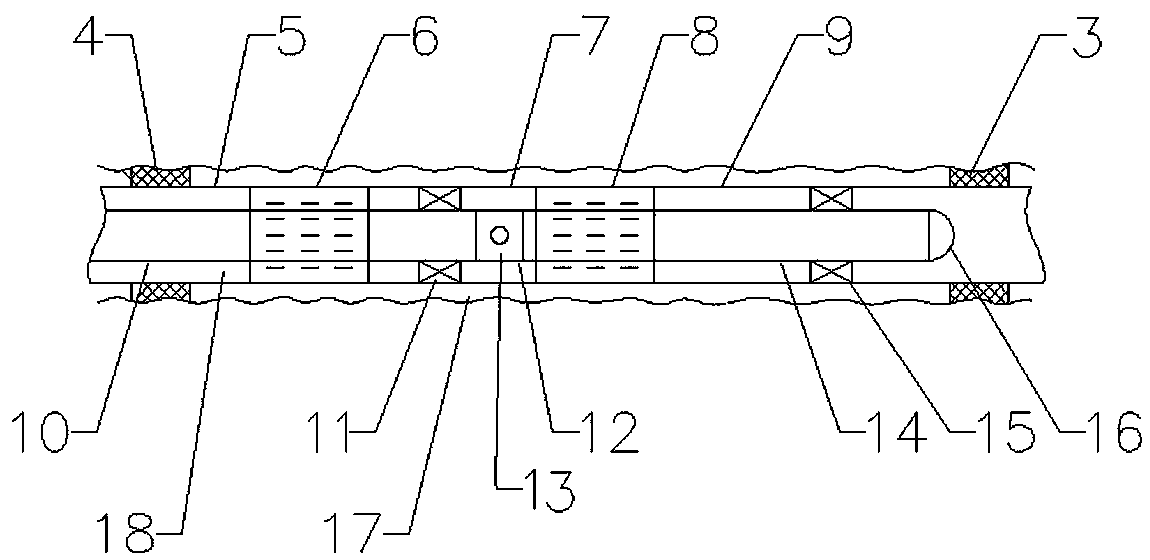

[0021] Specific embodiment one of the horizontal well staged pickling acidification method of the present invention, as figure 1 and figure 2 As shown, the staged pickling and acidizing method for horizontal wells includes completion strings and pickling strings. The completion string includes a liner hanger 1 and several sets of completion units 2. The number of sets of completion units 2 in the horizontal section is determined by the number of acidizing stages in the horizontal well; the completion unit 2 includes the first casing packer 4. The first casing 5 is provided on the right side of the first casing packer 4, and the first slotted screen 6 is threaded on the right side of the first casing 5, and the first slotted screen 6 constitutes the outlet Liquid screen pipe, the right side of the first slotted screen pipe 6 is threaded with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com