Basalt fiber asphalt pavement structure

A kind of asphalt pavement and basalt technology, which is applied to roads, roads, on-site coagulation pavement, etc., can solve the problems of inability to adapt, resistance to high temperature deformation and crack performance, etc., to achieve resistance to high temperature deformation, rutting, The effect of solving road noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Attached below figure 1 , attached figure 2 The present invention will be further described in detail with specific embodiments, and it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

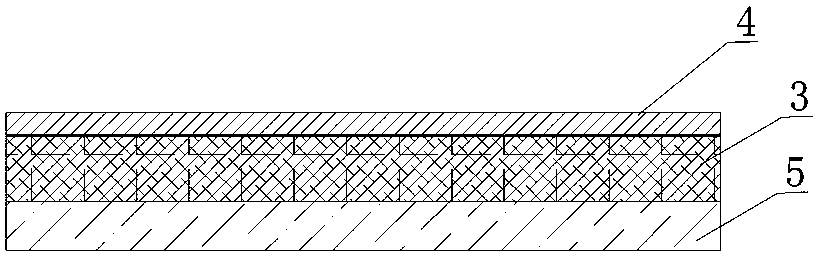

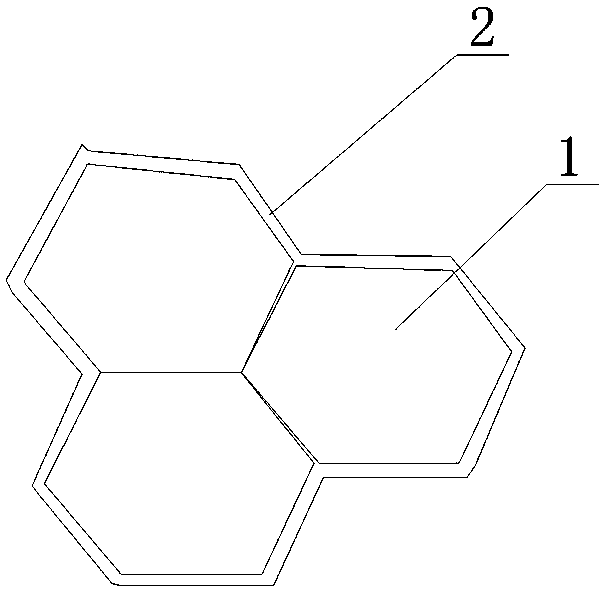

[0014] Such as figure 1 , figure 2 As shown, a basalt asphalt pavement structure includes a cushion layer 5, a base layer and a surface layer, the base layer is a basalt asphalt base layer 3, and the basalt asphalt base layer 3 is connected to each other by several basalt asphalt base structure units to form a network topology , that is to say, the basalt asphalt base structure units are closely arranged and laid one by one. The basalt asphalt base structure unit includes three benzene ring-connected basalt prefabricated blocks 1, the outer layer of the basalt prefabricated block 1 is an asphalt frame 2, and the basalt asphalt base structure unit is made of basalt m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com