Convection plate structure

A convection plate and bottom-end technology, applied in the field of metallurgy, can solve the problems such as the inability to solve the problems of the outer side of the small coil at the welding seam position, the size and specification, the surface morphology are different, and the effective operation rate of the heat treatment unit is affected, so as to reduce energy consumption and manpower. The effect of waste of resources, improvement of product quality, and improvement of operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

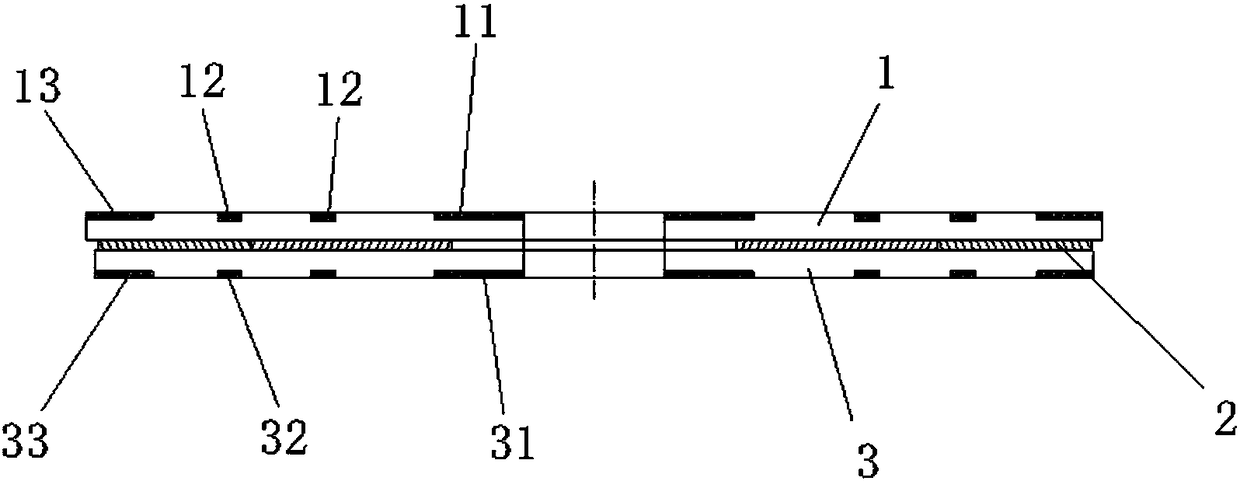

[0017] The present invention will be described in detail below with reference to the drawings, such as figure 1 As shown, the realization process of the technical solution of the present invention is divided into five steps, namely, the optimization of the surface shape of the convection plate, the improvement of the production material, the design of the size specification, the verification of the optimization design effect, and the economic benefits obtained.

[0018] Optimization of convection disk surface morphology

[0019] According to the analysis of the morphological characteristics of the damage caused by the convection plate to the stacked steel coils, the surface morphology of the upper and bottom end plates of the convection plate is redesigned.

[0020] The surfaces of the upper end plate and the bottom end plate of the convection plate are cut. The cutting area is divided into three areas, namely the inner cutting area, the outer cutting area and the middle cutting area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com