Organic tanning agent for leather and preparing method of organic tanning agent

An organic and leather technology, applied in the field of organic tanning agents for leather and its preparation, can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

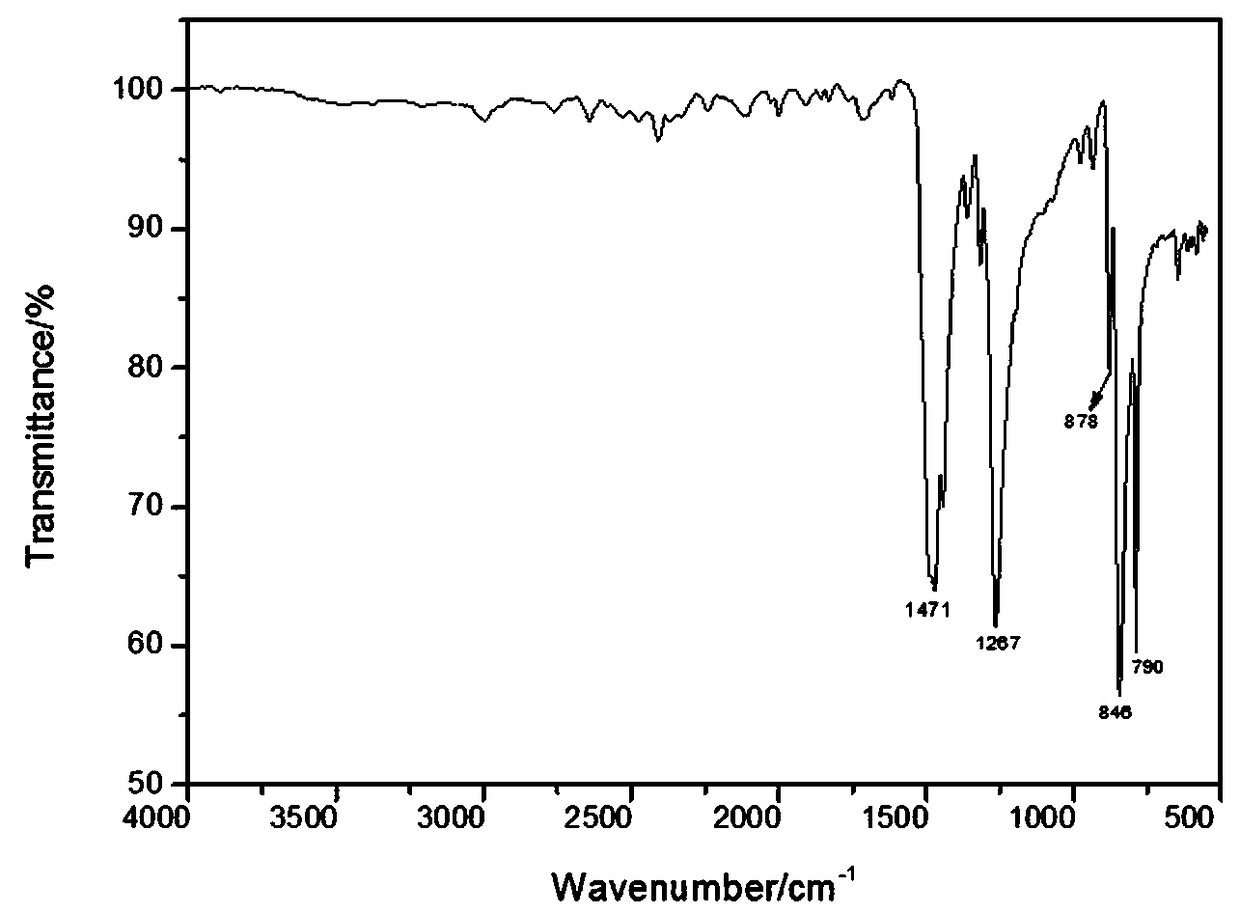

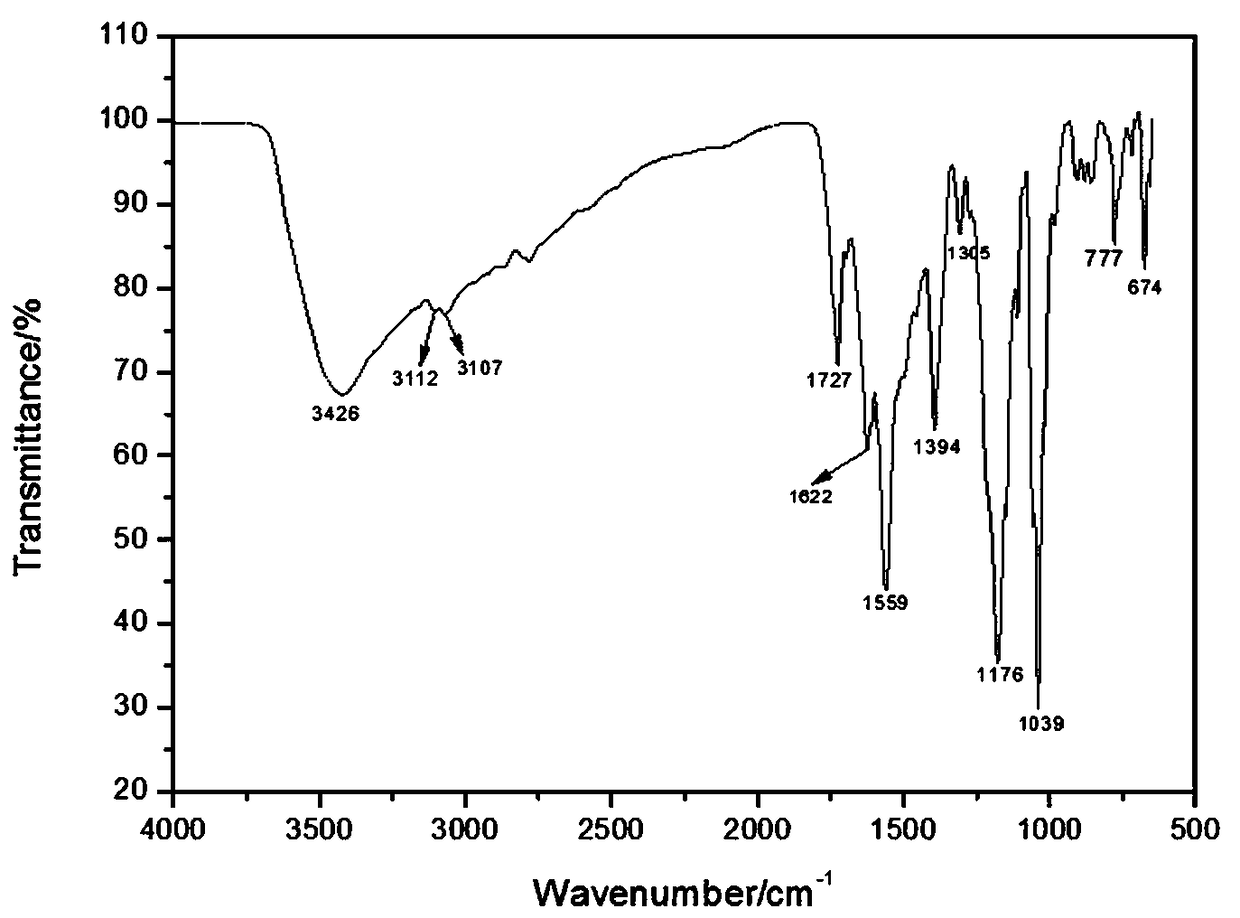

Image

Examples

Embodiment 1

[0036] Embodiment one: the experimental procedure of H acid and cyanuric chloride reaction

[0037] 5.59g of cyanuric chloride (TCT) was added into a 100mL three-necked flask, and 17.46g of water was added at room temperature. Put it into a pre-prepared constant temperature water bath with a temperature controlled at 0-5°C, and stir with a stirring bar for 20 minutes to cool the solution to 0-5°C. Add 11.26g of lysine to 26.53g of 12.23% sodium carbonate aqueous solution, mix evenly and place it in a beaker, and use a peristaltic pump to drop it into a three-necked flask at a speed of 0.5mL / min. 19.9 g of 12.23% sodium carbonate aqueous solution was added dropwise into the funnel, and the addition was completed in 60 minutes. The pH value was measured every 30 minutes to monitor the reaction progress, and the reaction was kept at 0-5° C. for 5 hours. After the reaction, an aqueous dispersion with a solid content of 25% was obtained, ready for use.

Embodiment 2

[0038] Embodiment two: the experimental procedure of taurine and cyanuric chloride reaction

[0039] 5.59g of cyanuric chloride (TCT) was added into a 100mL three-necked flask, and 27.94g of acetone was added at room temperature to dissolve the cyanuric chloride. Put it into a pre-prepared constant temperature water bath pot with a temperature controlled at 0-5°C, and stir for 20 minutes with a stirring bar, so that the temperature of the solution is lowered to 0-5°C to form a saturated solution. 3.99g taurine was added into 33.69g mass fraction of 10% sodium carbonate aqueous solution, mixed uniformly and placed in a beaker, and was added dropwise to a three-necked flask at a speed of 0.5mL / min by a peristaltic pump, and the addition was completed in 60 minutes. The pH value was measured every 30 minutes in order to monitor the progress of the reaction, and the reaction was incubated at 0-5°C for 5 hours. A reaction solution with a solid content of 15.7% was obtained and was...

Embodiment 3

[0040] Embodiment three: the reaction of lysine and cyanuric chloride

[0041] 5.59g of cyanuric chloride (TCT) was added into a 100mL three-necked flask, and 38.4g of acetone was added at room temperature to dissolve the cyanuric chloride. Put it into a pre-prepared constant temperature water bath pot with a temperature controlled at 0-5°C, and stir for 20 minutes with a stirring bar, so that the temperature of the solution is lowered to 0-5°C to form a saturated solution. Add 2.84g of lysine to 12.96g of 20% sodium hydroxide aqueous solution, mix evenly and place it in a beaker, and drop it into a three-necked flask with a peristaltic pump at a speed of 0.5mL / min. After 30 minutes, the addition is complete. The pH value was measured every 30 minutes in order to monitor the progress of the reaction, and the reaction was incubated at 0-5°C for 5 hours. A reaction solution with a solid content of 18% was obtained and was ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com