Lithium battery tool transfer machine

A transporter and lithium battery technology, applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of high cost, unsafe operation, occupying a lot of space, etc., and meet the requirements of reducing production costs and high requirements. Low, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

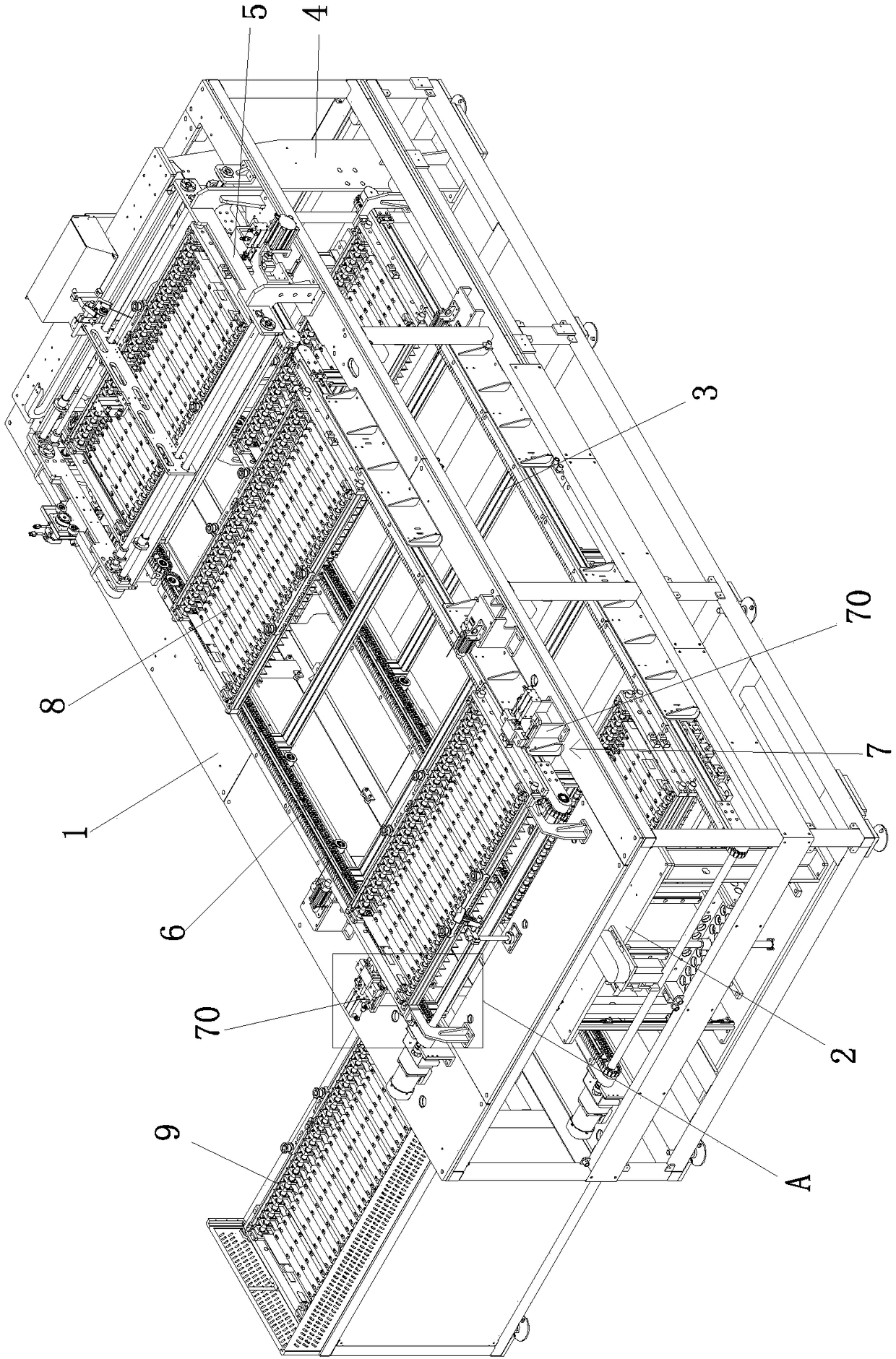

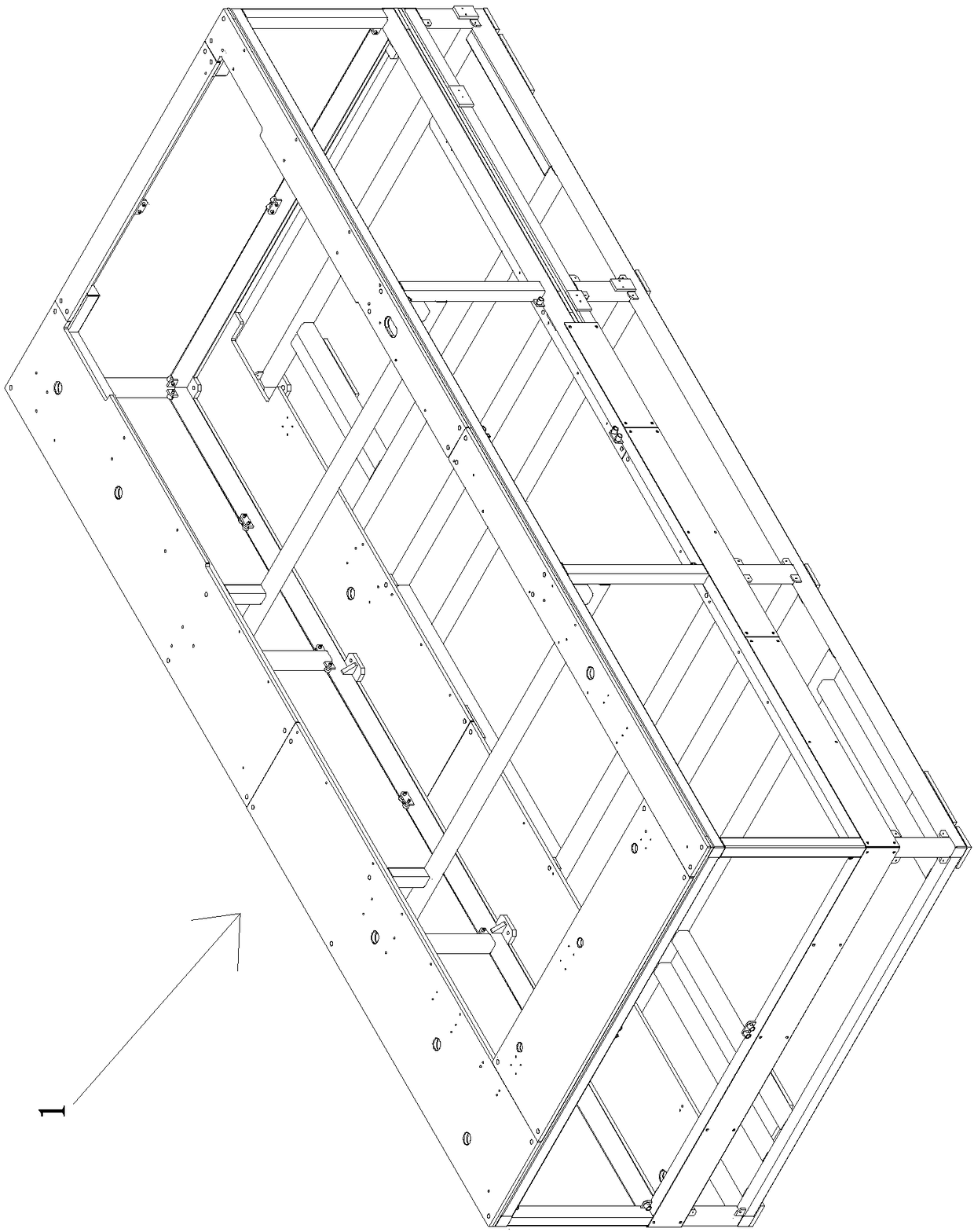

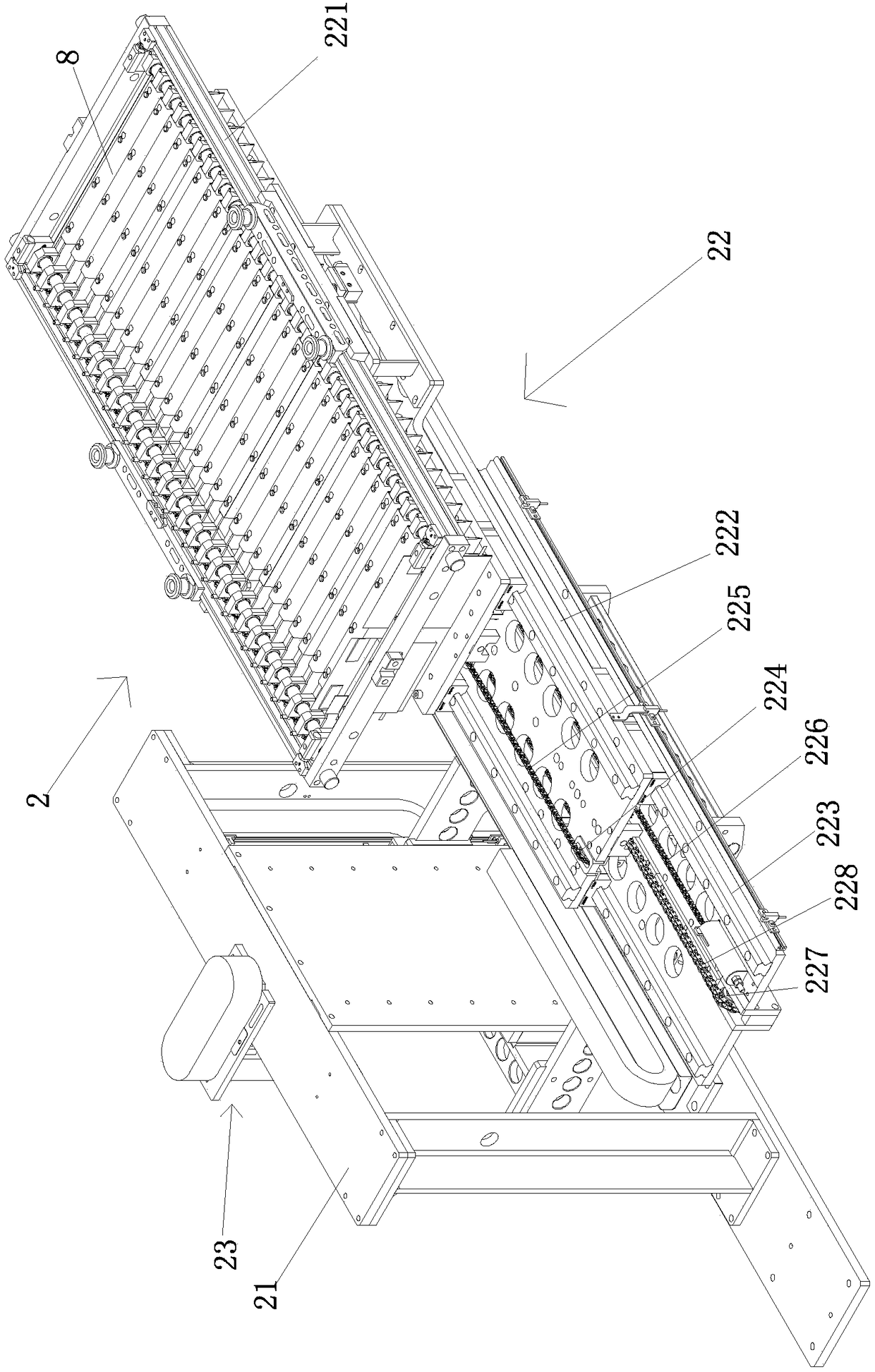

[0033] Such as figure 1 , 2, 3, and 4, the lithium battery tooling transfer machine of the present invention includes a frame-shaped frame 1, and the frame 1 is provided with upper and lower layers, and the lithium battery tooling transfer machine also includes a The tooling telescopic mechanism 2 used for loading in the left end, the lower layer conveying mechanism 3 arranged on the lower layer of the frame 1 for conveying tooling extending left and right, and the lower layer conveying mechanism 3 arranged in the right end of the frame 1 for transferring the tooling The tooling sent by the lower conveying mechanism 3 is transferred to the jacking mechanism 4 on the upper layer of the frame 1, and the opening and closing conveying mechanism 5 arranged on the right side of the upper end of the frame 1 for receiving the tooling conveyed by the jacking mechanism 4 , the upper conveying mechanism 6 located on the left side of the opening and closing conveying mechanism 5 and exte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap