Beam-adjustable femtosecond laser machining device

A femtosecond laser and processing device technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of difficult control of the size of the pipe processing area, achieve real-time optimization of laser processing parameters, improve performance, and reduce post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

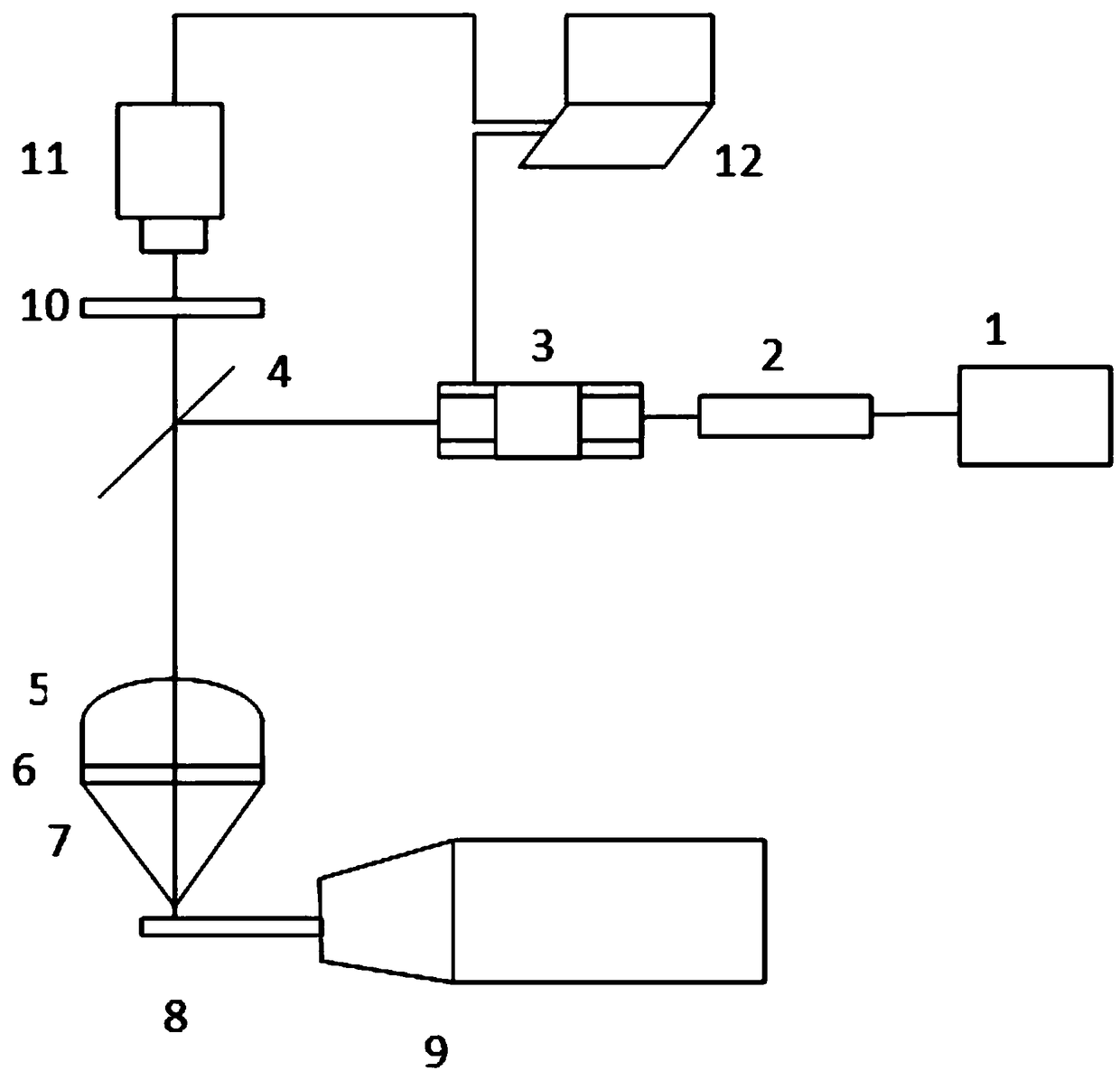

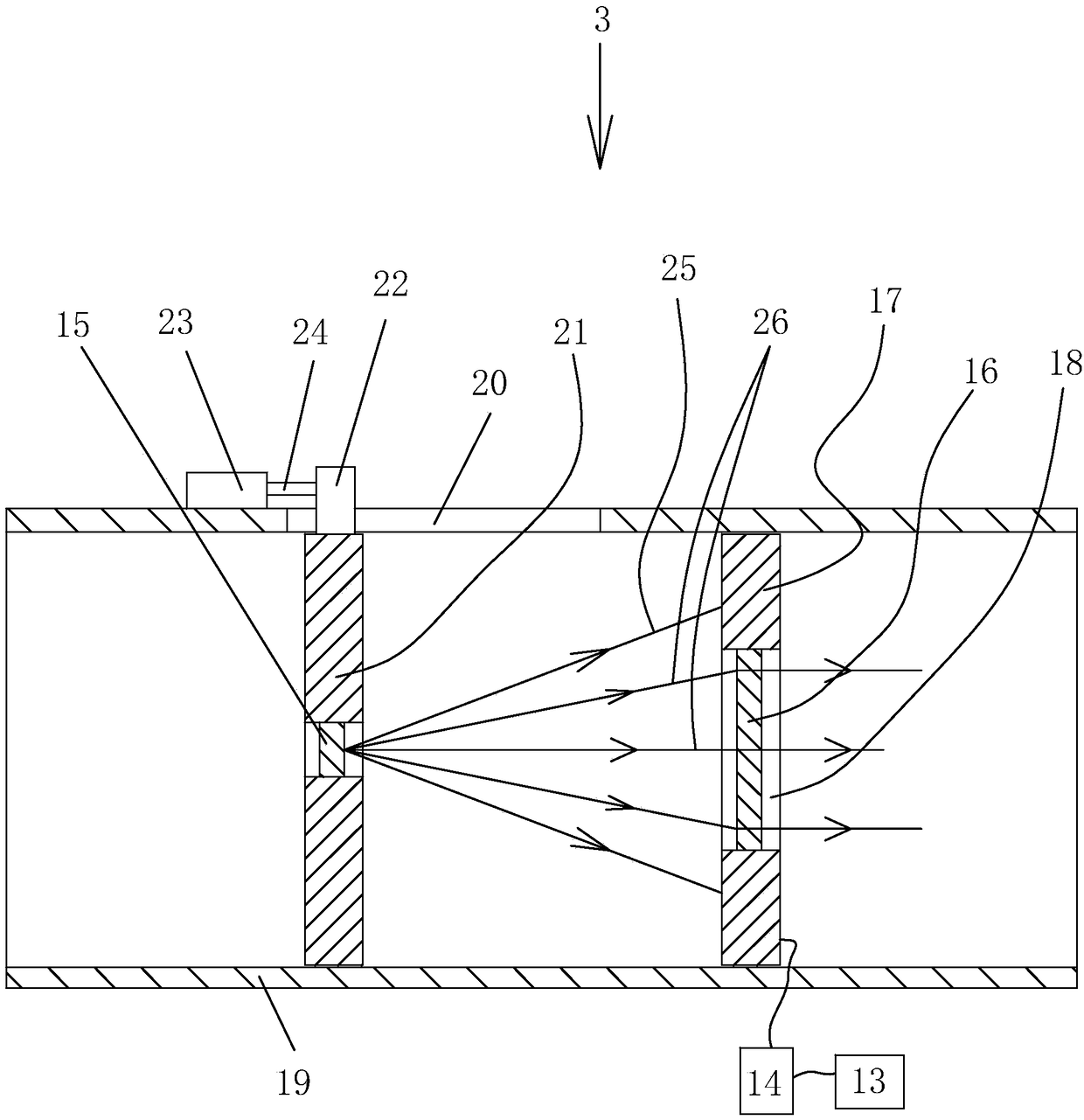

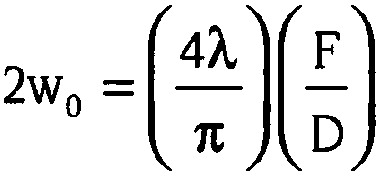

[0029] Embodiment, adjustable beam femtosecond laser processing device, see Figure 1-Figure 2 As shown, it includes an ultrafast laser 1, an ultrafast laser isolator 2, a laser beam expander with adjustable magnification 3, a mirror 4, a focusing lens 5, a protective glass 6, a laser cutting nozzle 7, a working table 9, and a filter chip 10, CCD camera 11 and control unit 12, the laser light output by the ultrafast laser 1 passes through the ultrafast laser isolator 2, laser beam expander 3 with adjustable magnification, mirror 4, focusing lens 5, protective glass 6 and the laser cutting nozzle 7 are irradiated on the work area 8 of the workbench, the control ends of the CCD camera and the laser beam expander are respectively connected with the control unit, and the lens of the CCD camera is arranged towards the work area of the workbench, so The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com